Laser impact method for extrusion die key part

A technology for extrusion dies and key parts, which is applied in the field of surface laser shock strengthening of key parts of extrusion dies. It can solve problems such as die damage and product quality affecting the service life of the die, so as to ensure quality and performance, improve service life and production. Efficiency, improve the effect of stress corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Select the extrusion punch made of H13 material, at the quenching temperature of 1020-1060°C and tempering temperature of 560-650°C, increase its hardness, improve its internal microstructure and stress state, so that the surface hardness value after heat treatment is 52HRC, the surface The roughness reaches 0.12μm. Through the comparison of the extrusion punch before and after use, it is found that the outer surface of the extrusion punch has the most severe friction and wear when it is working.

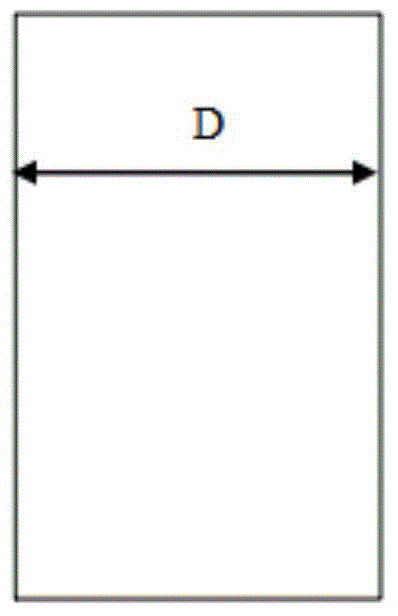

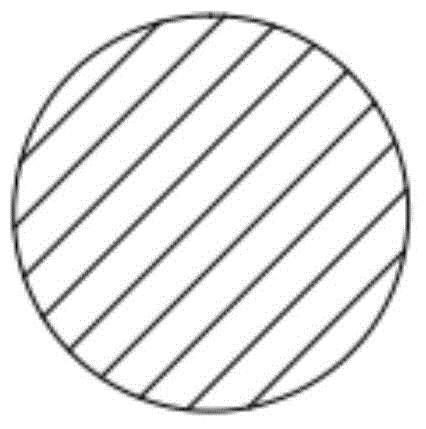

[0031] From figure 1 and figure 2 It can be seen from the figure that the outer surface of the extrusion punch is cylindrical, so the laser impact path is gradually impacted along the outer cylindrical surface of the extrusion punch from top to bottom until the impact is completed; the laser impact parameters are as follows: The area to be impacted by the punch is coated with 0.2mm black paint as the absorbing layer, and the 0.3mm water flow layer is used as the confinement...

Embodiment 2

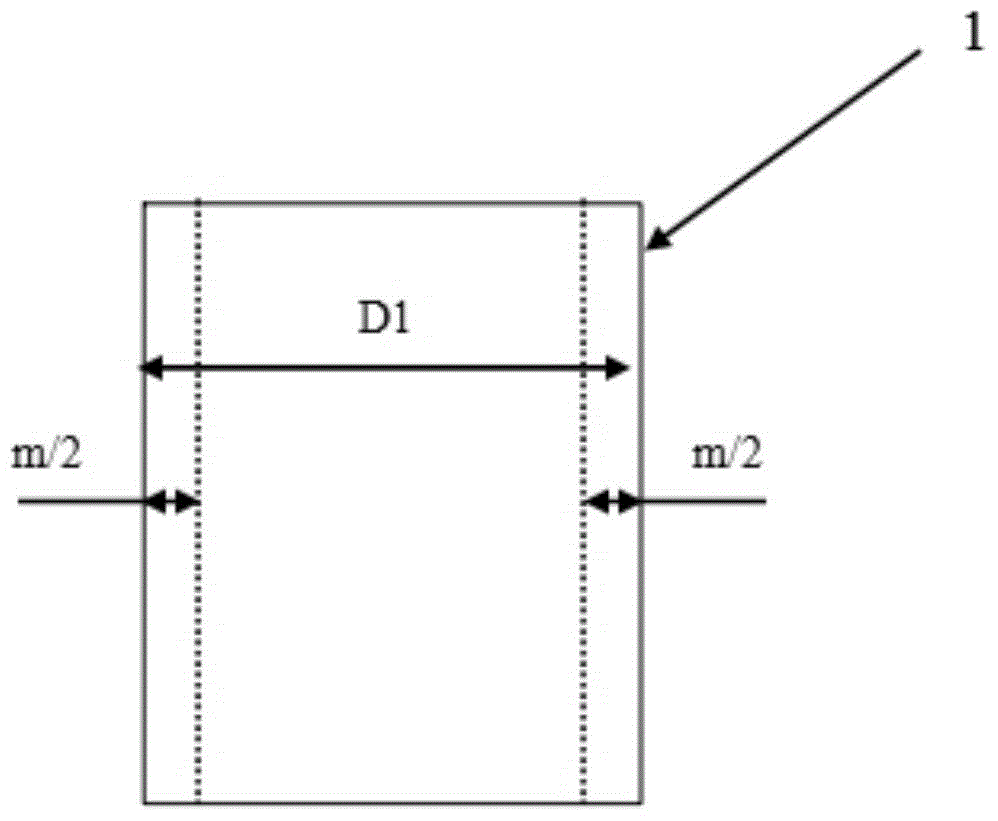

[0033] Firstly, the material W18Cr4V used in the extrusion die is heat-treated, the quenching temperature is 1200-1240°C, and the tempering temperature is 550-700°C to increase its hardness, improve its internal microstructure and stress state. After heat treatment, its surface hardness value is 56HRC. The roughness reaches 0.09μm. Through the comparison of the extrusion die before and after use, it is found that the inner surface of the extrusion die has the most severe friction and the most serious wear during operation. From Figure 4 and Figure 5 It can be seen from the figure that the inner surface of the extrusion die is a cylindrical surface, so the laser impact path gradually impacts along the inner cylindrical surface of the extrusion die from top to bottom until the impact is completed; the laser parameters are: A 0.2mm black paint is applied to the area to be impacted on the concave die as an absorbing layer, and a 0.3mm water flow layer is used as a confinement la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| energy | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com