Method of separating indium from tin slag

A technology of tin slag and alkaline solution, applied in the direction of improving process efficiency, etc., can solve the problem of incomplete separation, and achieve the effect of complete separation, low cost and simple operation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

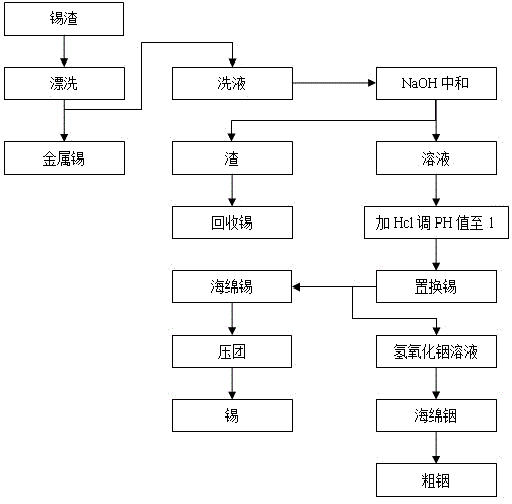

[0010] Such as figure 1 As shown, the present invention separates the method for indium from tin slag, and the steps of this method are as follows: the tin slag is rinsed with water, and the tin that becomes metal element is washed out, and the cleaning solution after rinsing is added NaOH alkali solution, and the pH value is adjusted to 2 , the tin in the solution reacts with NaOH to form and , standing will and Precipitation is precipitated, and the filtered filtrate is added with a 31% hydrochloric acid solution to adjust the pH value to 1.5. The remaining tin is replaced with an indium plate, and finally the indium in the solution is replaced with an aluminum plate. The invention can effectively separate the indium from the substituted tin colloidal precipitate, the operation method is simple, the cost is low, the indium is completely separated, and the recovery rate of the indium reaches 97% through the separation.

Embodiment 2

[0012] Such as figure 1 As shown, the present invention separates the method for indium from tin slag, and the steps of this method are as follows: the tin slag is rinsed with water, and the tin that becomes metal element is washed out, and the cleaning solution after rinsing is added NaOH alkali solution, and the pH value is adjusted to 2.5 , the tin in the solution reacts with NaOH to form and , standing will and Precipitation is precipitated, and the filtered filtrate is added with a 31% hydrochloric acid solution to adjust the pH value to 1. The remaining tin is replaced with an indium plate, and finally the indium in the solution is replaced with an aluminum plate. The recovery rate of indium of the present invention reaches 98%.

Embodiment 3

[0014] Such as figure 1 As shown, the present invention separates the method for indium from tin slag, and the steps of this method are as follows: the tin slag is rinsed with water, and the tin that becomes metal element is washed out, and the cleaning solution after rinsing is added NaOH alkali solution, and the pH value is adjusted to 3 , the tin in the solution reacts with NaOH to form and , standing will and Precipitation is precipitated, and the filtered filtrate is added with a 31% hydrochloric acid solution to adjust the pH value to 1.5. The remaining tin is replaced with an indium plate, and finally the indium in the solution is replaced with an aluminum plate. The recovery rate of indium of the present invention reaches 97%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com