Real-time monitoring device for pavement paving thickness and ironing vibration frequency

A vibration frequency and real-time monitoring technology, applied to measuring devices, roads, roads, etc., can solve problems such as poor vibration uniformity, poor representation, and low detection frequency, and achieve the effects of reducing errors, improving efficiency, and realizing control and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

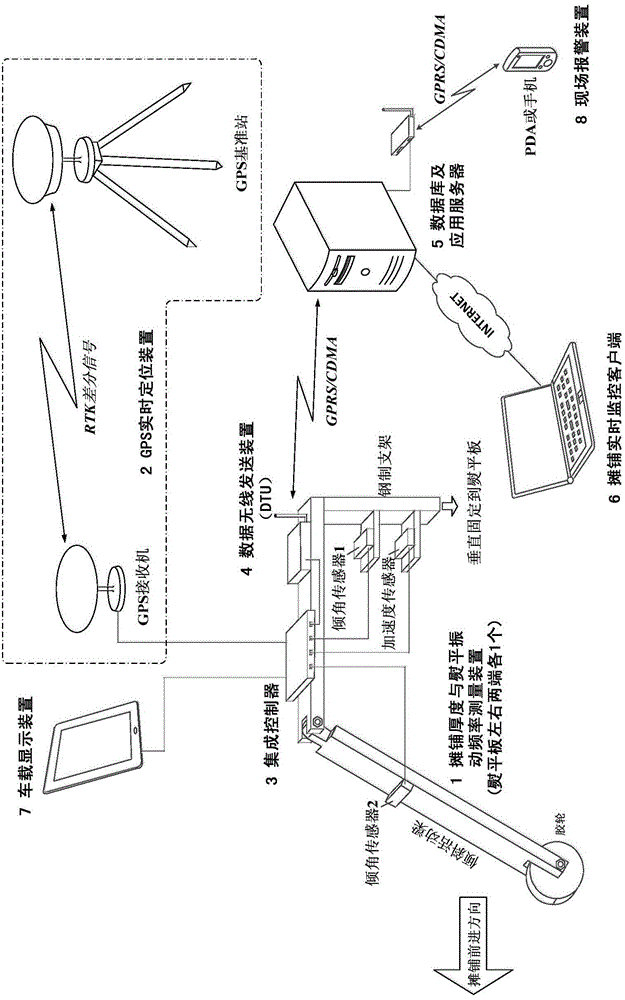

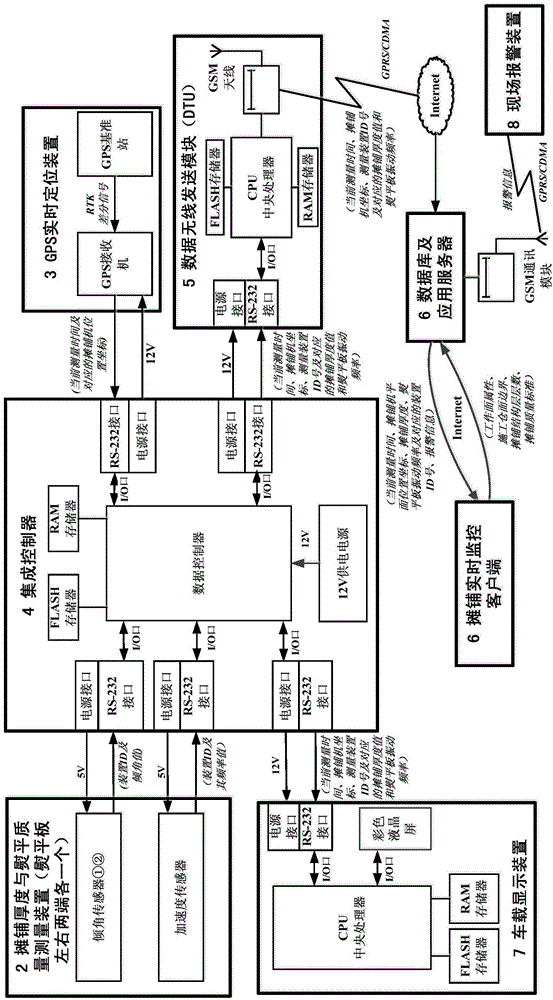

[0043] The structure of this device is shown in figure 1 , including: paving thickness and screed vibration measuring device (one at each end of the screed), GPS real-time positioning device, integrated controller, data wireless transmission unit (DTU), database and application server, paving real-time monitoring client , on-board display device, on-site alarm device, a total of 8 parts.

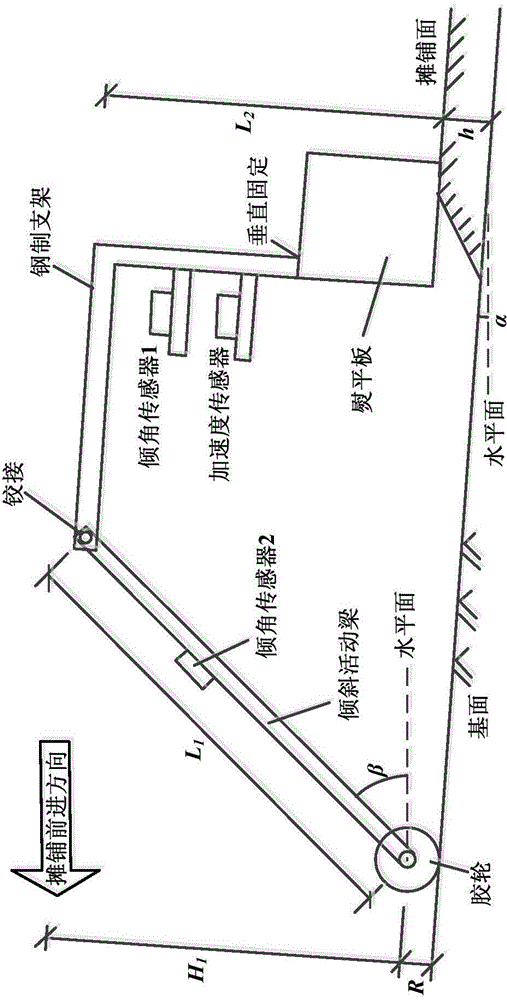

[0044] The paving thickness and screed vibration measuring device includes steel brackets, inclined movable beams, rubber wheels, acceleration sensors, and inclination sensors (2). One end of the steel bracket is hinged to the inclined movable beam, and the other end is vertically fixed on the paver screed. The rubber wheel connected to the end of the inclined movable beam is in contact with the roadbed surface, so that the measuring device travels together with the paver. Each paver is equipped with two sets of paving thickness and screed vibration measuring devices, which are respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com