Leakage-proofing process for exploiting hot-dry-rock geothermal resource by injecting CO2 (supercritical carbon dioxide)

A supercritical, dry hot rock technology, applied in the field of leakage prevention, can solve problems such as safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

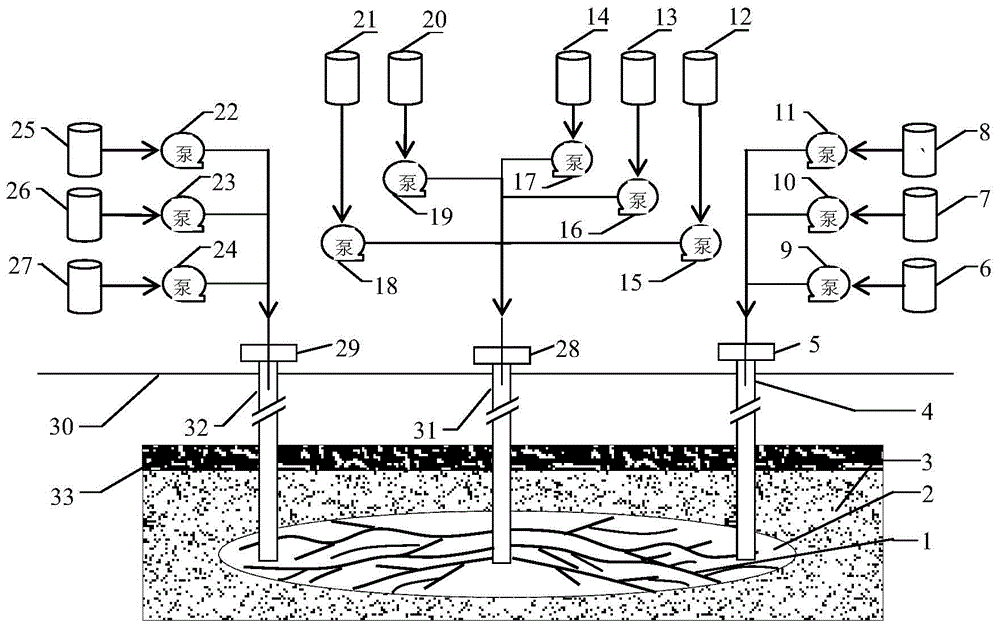

[0040] The present invention will be further described below in conjunction with accompanying drawing.

[0041] inject supercritical CO 2 The leakage prevention technology for exploiting hot dry rock geothermal heat, the specific steps are as follows:

[0042] (1) Through preliminary geological exploration, select a suitable location for the hot dry rock reservoir, and drill the injection well 31;

[0043] (2) Using injection pumps 18 and 19, the water-based fracturing fluid and proppant in the storage tanks 21 and 20 are injected into the hot dry rock reservoir 3 with a large displacement through the wellhead device 28 of the injection well 31, and the Hydraulic fracturing, construction of artificial geothermal reservoirs, a well needs to inject about 10000m 3 For water, the radius of the artificial heat storage is 500-1000m, and the thickness is 500-1000m.

[0044] (3) A production well is drilled on both sides of the injection well 31, and the production wells 4 and 32 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com