Rectangular pipe jacking machine tunnel entering auxiliary structure and construction method

A technology of rectangular pipe jacking and construction methods, which is applied to earth drilling, mining equipment, tunnels, etc., and can solve problems such as the inability of rectangular pipe jacking machines to enter holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

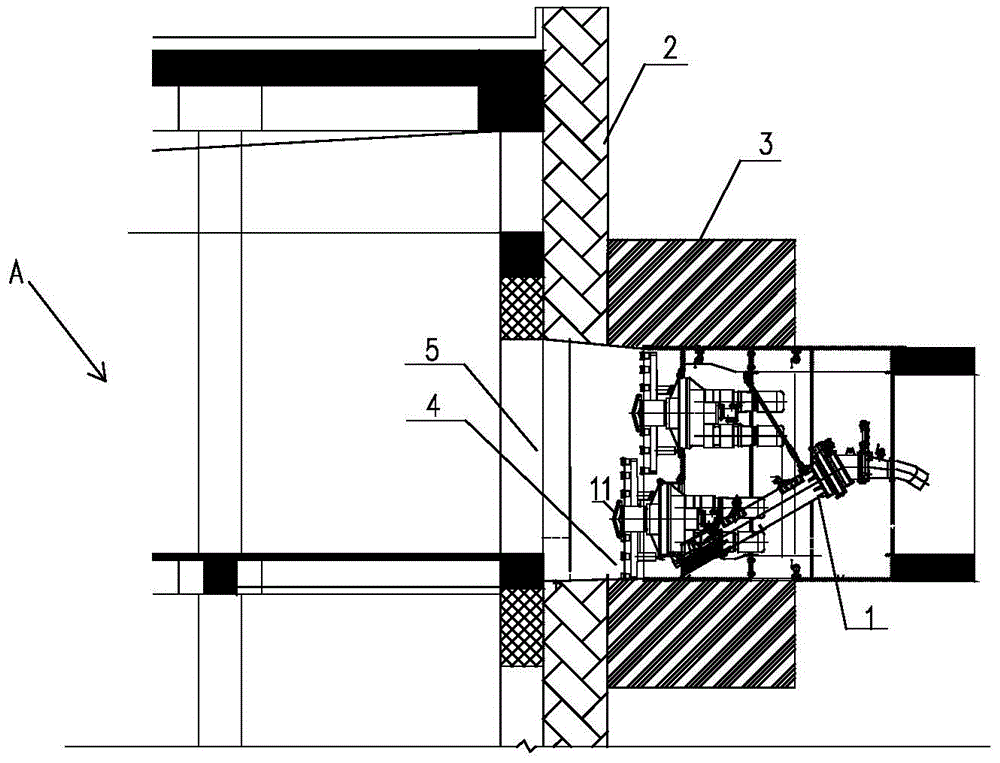

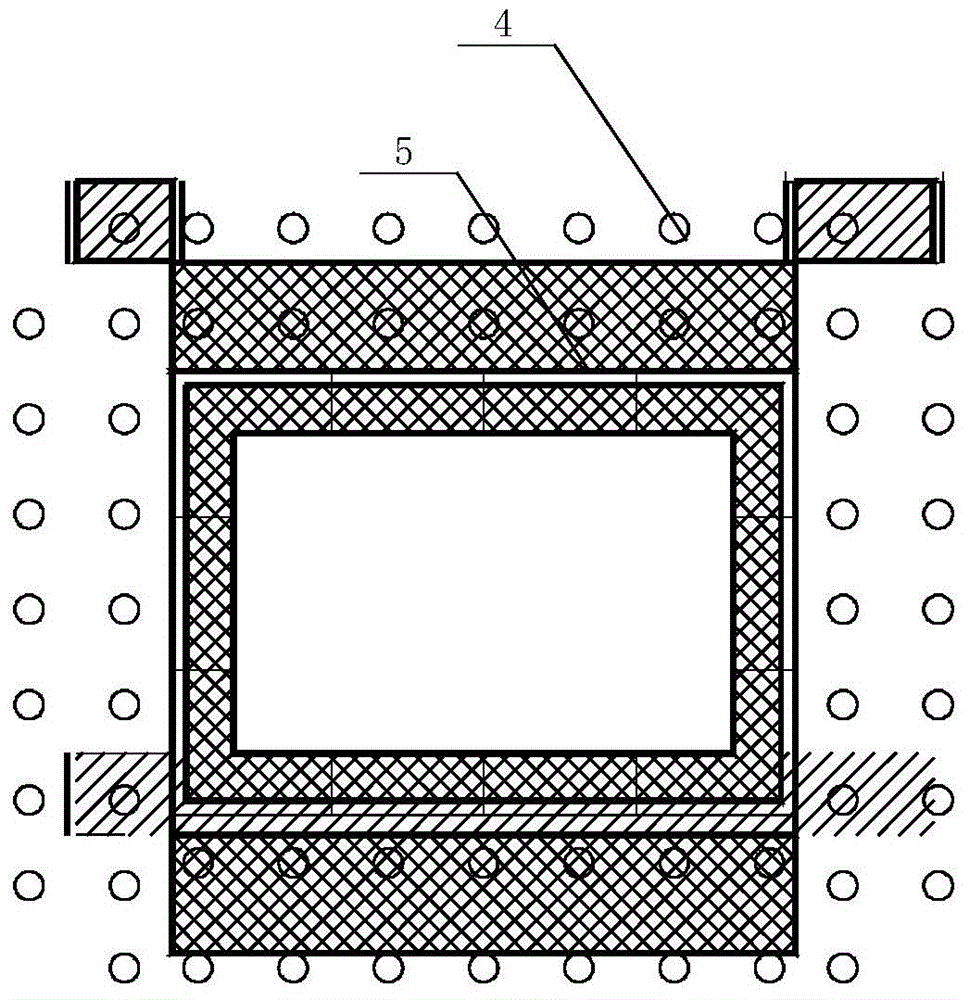

[0030] Combine below figure 1 and figure 2 The auxiliary structure for entering the hole of the rectangular pipe jacking machine of the present invention will be described in detail.

[0031] Such as Figure 1 to Figure 2 As shown, the auxiliary structure of the rectangular pipe jacking machine 1 entering the hole is suitable for the installation of the rectangular pipe jacking machine 1 when the receiving shaft cannot be installed in the existing building A and the cutter head 11 of the rectangular pipe jacking machine 1 is close to the underground diaphragm wall 2 Entering the hole, including the door reinforcement freezing structure 3 and the steel frame structure 4, the door reinforcement freezing structure 3 is arranged longitudinally along the 5th circle of the door; the steel frame structure 4 is an assembled closed steel structure with openings at both ends, and the steel frame structure 4 The openings at both ends of the opening match the shape and size of the door...

Embodiment 2

[0035] Continue to combine below figure 1 and figure 2 The construction method of the rectangular pipe jacking machine 1 entering the hole will be described in detail. The construction method for entering a hole with a rectangular pipe jacking machine 1 includes the following steps:

[0036] Step 1: Park the rectangular pipe jacking machine 1 at a predetermined position, so that the cutter head 11 of the rectangular pipe jacking machine 1 is close to the underground continuous wall 2 .

[0037] Specifically, firstly, check the centers of the starting portal and the receiving portal 5 of the rectangular pipe jacking machine 1 . According to the center positions of the two portals, the actual slope and distance of the rectangular pipe jacking machine 1 are measured and calculated, and the best stop position of the rectangular pipe jacking machine 1 is simulated. When the distance from the underground diaphragm wall 2 of the receiving portal 5 is about 5 meters, the constructio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com