Gas valves for different gas sources

A gas valve and gas source technology, applied in the direction of valve devices, cocks including cut-off devices, engine components, etc., can solve the problems of inconvenient installation and maintenance of valve cores, reduced service life of gas valves, complex adjustable structure of valve cores, etc. , to achieve the effect of ensuring strength, reducing production and assembly costs, and requiring high processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

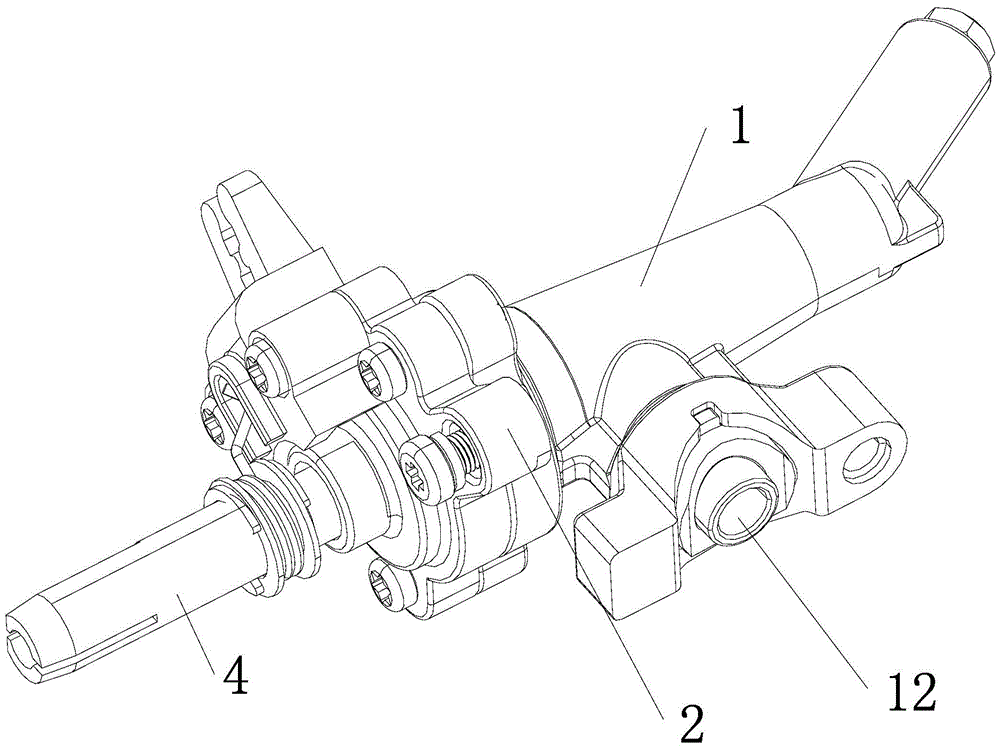

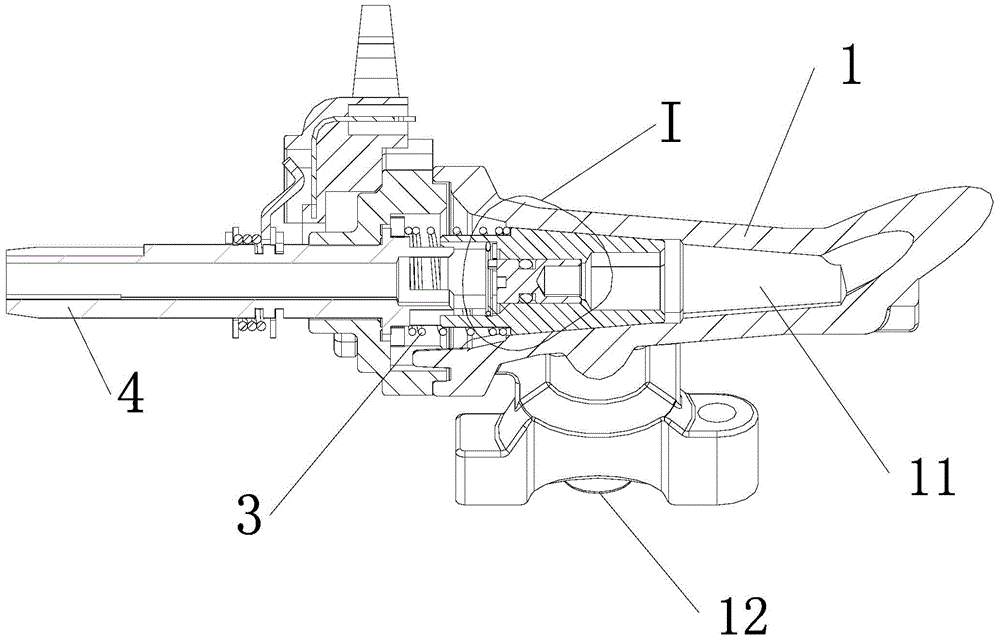

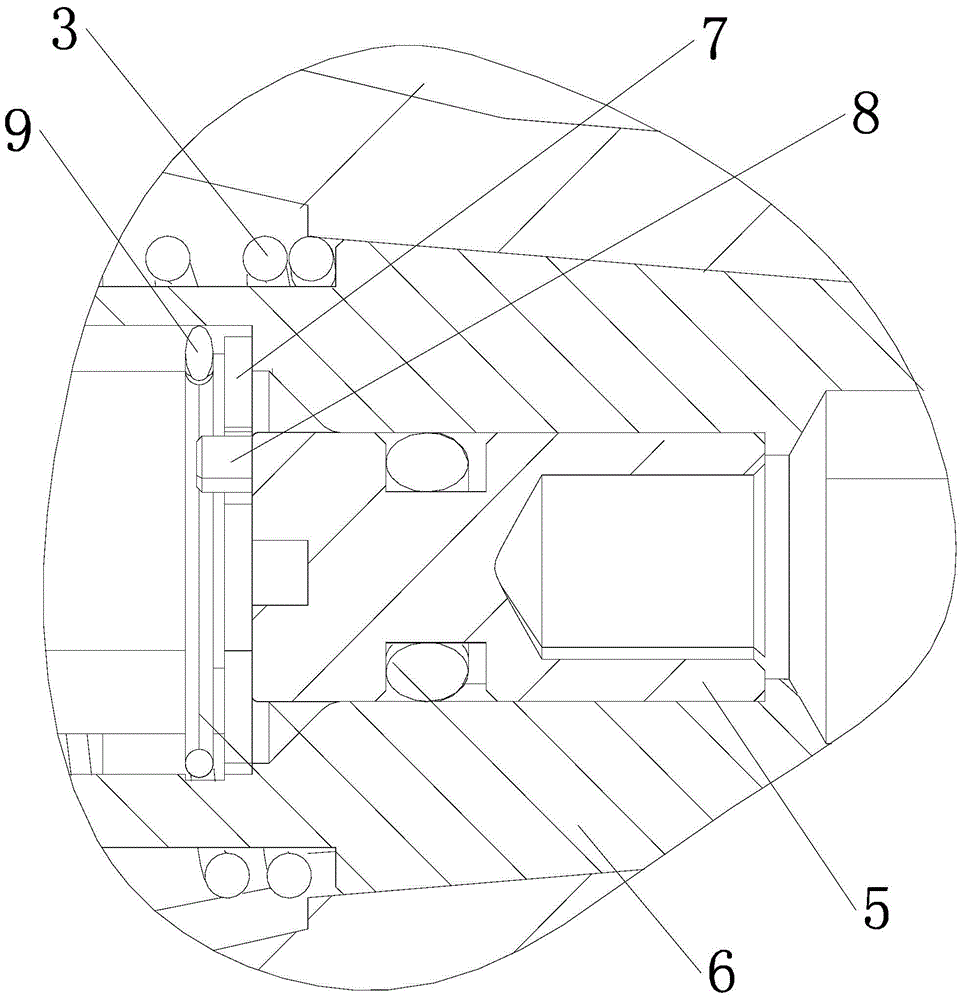

[0020] The present invention is a gas valve applicable to different gas sources, such as Figures 1 to 5 Shown, comprise valve body 1, valve seat 2, spool, spool spring 3 and rotating shaft 4, described spool includes inner and outer spool 5,6, and described inner spool 5 is near rotating shaft 4 The surface of that end is provided with an adjusting port 51 for inserting a screwdriver to rotate the inner valve core 5; no matter whether it is NG or LP gas source in the present invention, they all share the same large fire intake channel, and are similar to the gas valve whose patent number is 200810030076.3 It is basically the same, and the outer valve core 6 is also provided with a large fire inlet hole 61 for communicating with the outlet passage 11 and the inlet passage 12 of the valve body; the difference is that the structure is simpler and more reasonable. and the micro-flame adjustment structure, for this reason, the outer valve core 6 is provided with the first and seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com