Cooling tower filler

A technology of cooling tower and packing sheet, applied in the field of cooling tower packing, can solve the problem of unsatisfactory cooling effect of the whole tower, and achieve the effect of long heat and mass exchange time, reasonable structure and improved cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

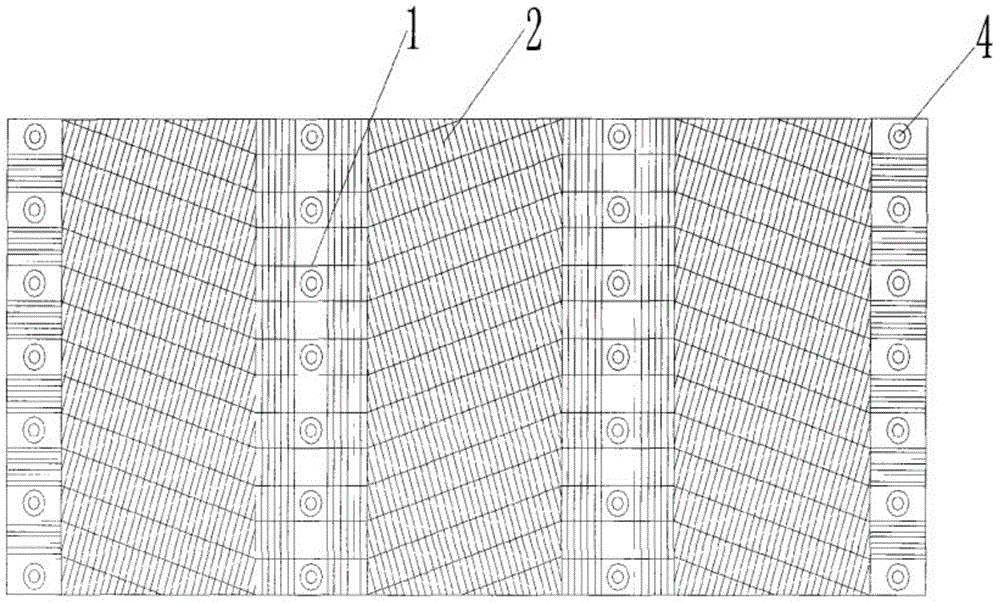

[0010] See figure 1 As shown, a cooling tower packing is composed of several packing sheets, each adjacent two packing sheets are stacked in dislocation to form a honeycomb structure, and each packing sheet includes several S-shaped corrugations 1 and several bonding points 4 , the S-shaped corrugations of each packing sheet are arranged with concavo-convex intervals. Each S-shaped corrugation 1 of each packing sheet is provided with equidistant corrugations 2, and each corrugation 2 is a trapezoidal ramp. The bonding points 4 are arranged at the peaks and valleys of each S-shaped corrugation 1 .

[0011] The specific embodiments described above have further described the purpose, technical solutions and beneficial effects of the present invention in detail. It should be understood that the above descriptions are only specific embodiments of the present invention and are not intended to limit the present invention. Any modifications, equivalent replacements, improvements, et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com