Method for monitoring laser melting pool in real time

A real-time monitoring and laser melting technology, applied in laser welding equipment, manufacturing tools, electrical radiation detectors, etc., can solve problems such as experimental result errors, inability to intuitively reflect real-time temperature changes, and achieve low cost, easy acquisition, analysis and processing. , the effect of high integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

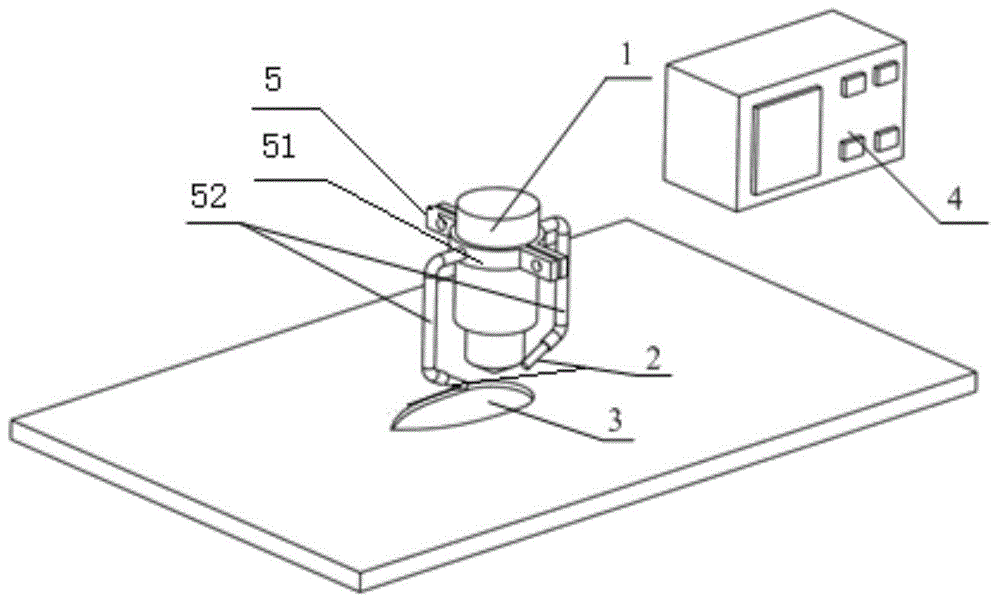

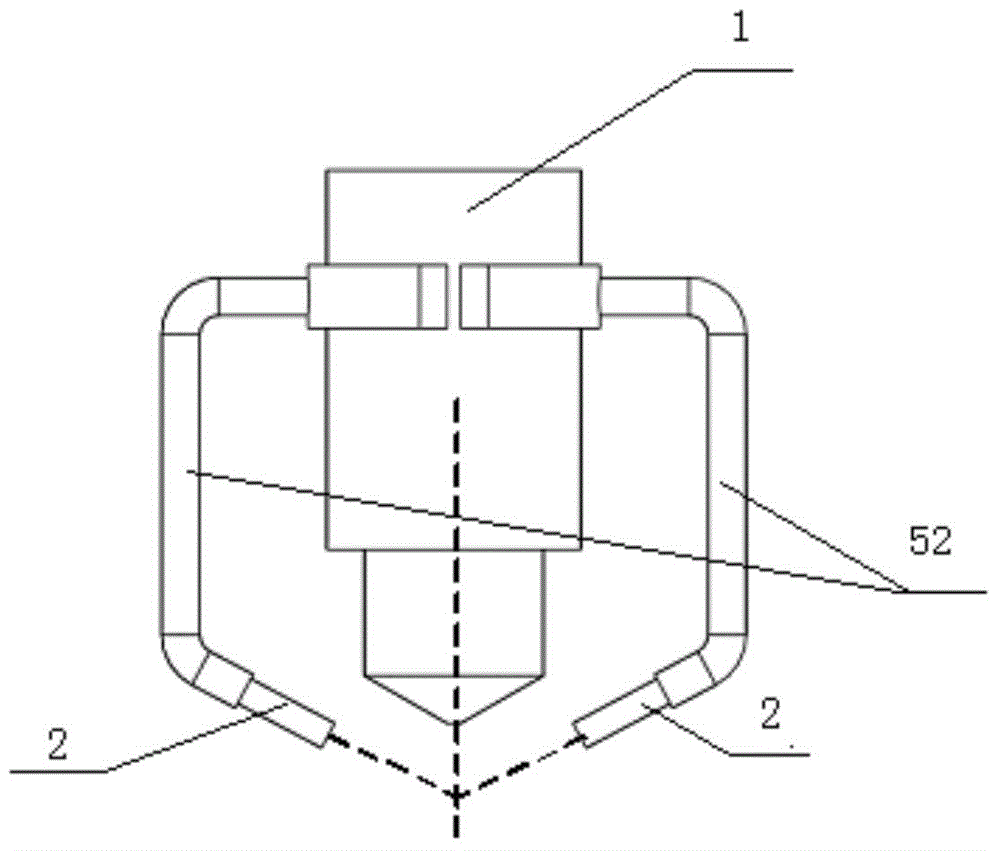

[0014] Such as figure 1 As shown, a laser melting pool real-time monitoring method has a support 5 installed on the main shaft; an infrared probe 2 and an alarm device for collecting the temperature information of the laser melting pool are installed on the support 5; it is used to process the temperature information collected by the infrared probe And there is a control box 4 with a display, and a control circuit is installed inside the control box 4, and the control circuit is connected to the power switch of the temperature field through a relay; the control circuit includes a central controller, which is respectively connected with the central controller for temperature measurement and analysis. display module, data storage module, communication module and power supply module,

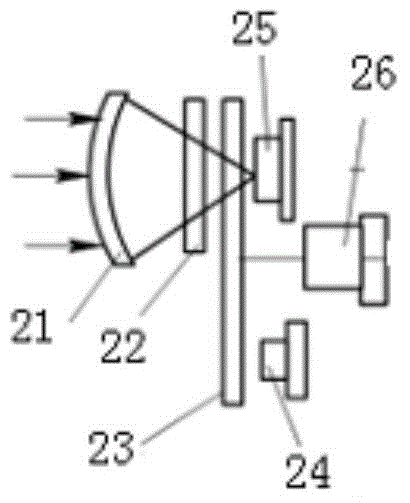

[0015] Such as figure 2 As shown, the infrared probe 2 is composed of a lens 21 , an optical filter 22 , a reticle 23 , a temperature compensation sensor 24 , a photosensitive element 25 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com