Rolling bearing fault diagnosis method using particle filtering and spectral kurtosis

A technology for fault diagnosis and rolling bearings, applied in the direction of mechanical bearing testing, etc., can solve problems such as difficult to diagnose bearing faults

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

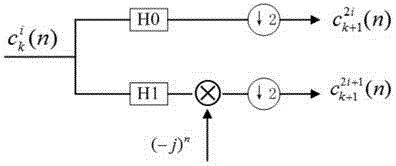

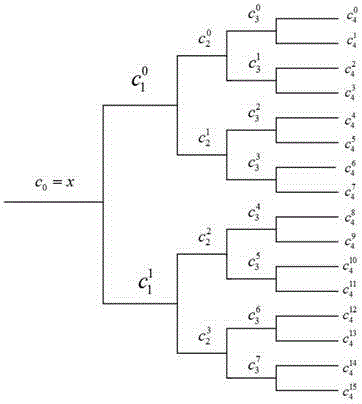

Method used

Image

Examples

Embodiment Construction

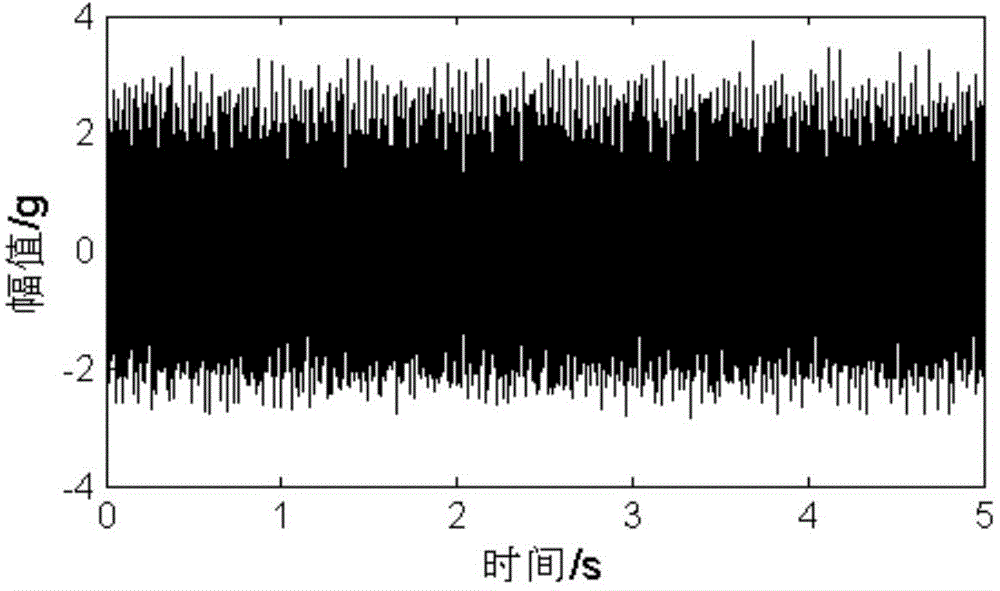

[0050] Embodiments of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings.

[0051] The data in the embodiment comes from Western Reserve University in the United States, and the data is the fault data of the bearing at the motor drive end. The bearing model is 6205-2RS JEM SKF, a deep groove ball bearing. Bearing parameters are shown in the table below:

[0052] Table 1 Bearing parameter table

[0053] Inner ring diameter

Outer ring diameter

thickness

Rolling body diameter D d

verse d m

Ball number Z

25mm

52mm

15mm

7.94mm

139.04mm

60°

9

[0054] The speed of the experimental motor is 1797rpm / m, and the fault size is 0.1778mm. The calculation formula of the fault characteristic frequency of the inner and outer rings is as follows: BPFI = Zf r ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com