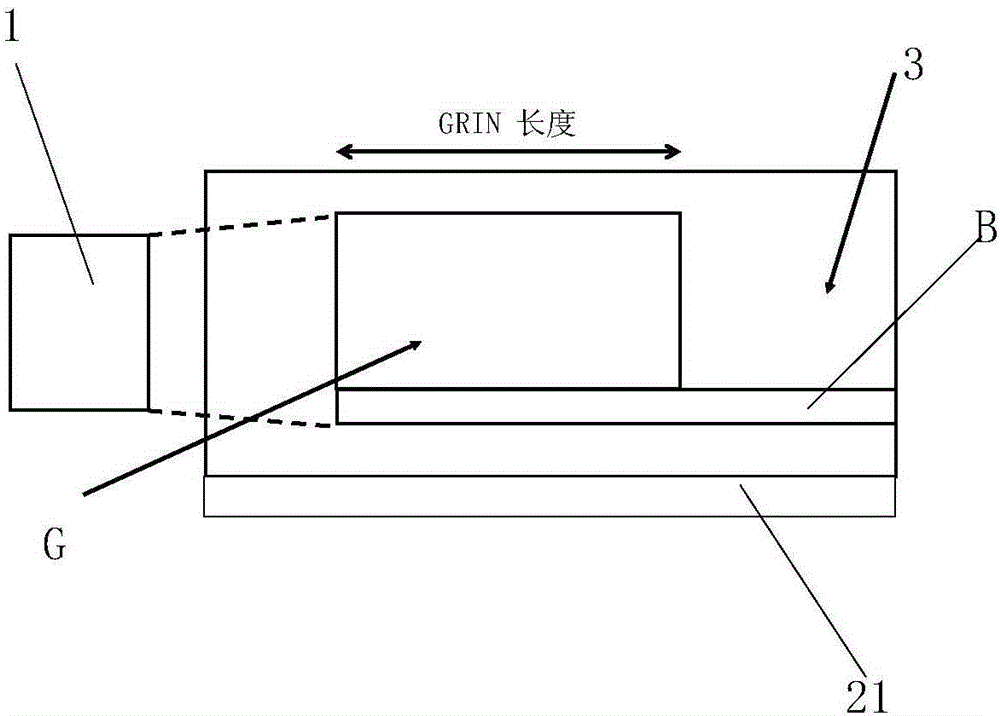

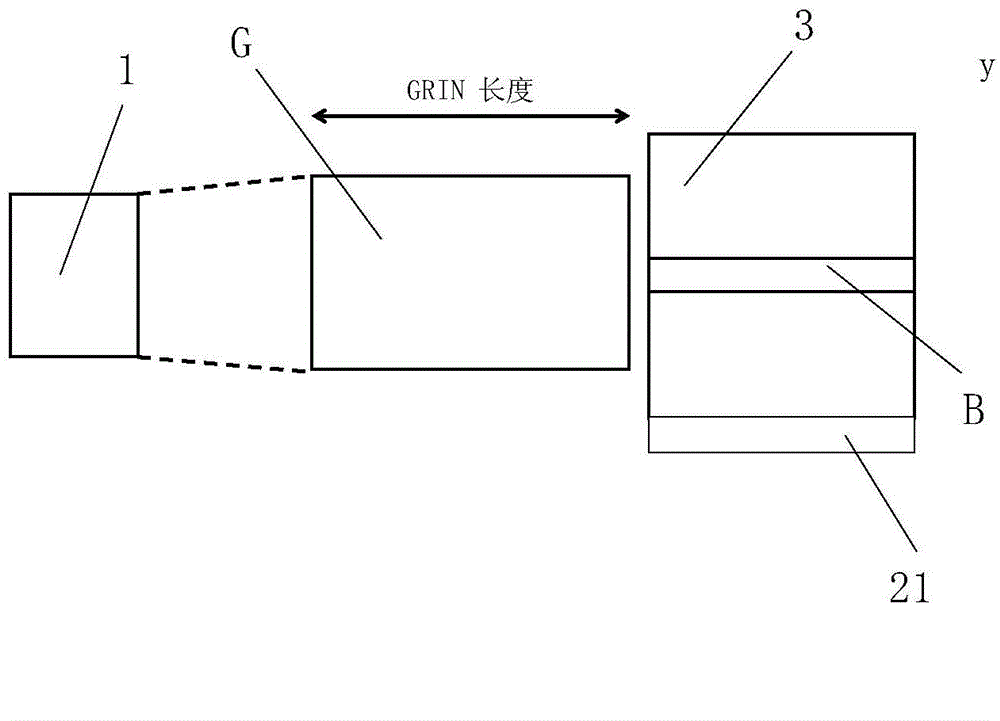

Gradient refractive index waveguide device and preparation method thereof

A gradient index, waveguide device technology, applied in the coupling of optical waveguides, light guides, optics, etc., can solve the problems of reduced precision, reduced fidelity, GRIN lens etching, etc., and achieves good reliability and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

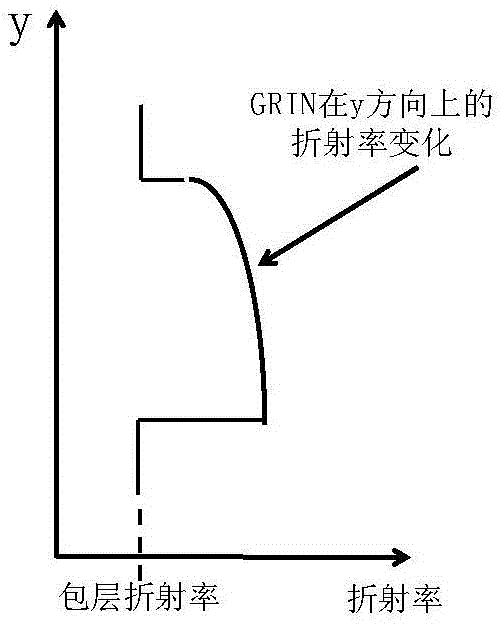

Method used

Image

Examples

Embodiment 1

[0065] The method of the invention performs the growth and etching of the GRIN element layer by layer. Such as Figure 6 The embodiment shown is a multilayer grown GRIN element. In the figure, G1, G2, G3, B, G4, G5, and G6 represent different layers, and T1, T2, T3, T4, T5, and T6 represent the thickness of each layer respectively. The GRIN lens is composed of seven layers, but it can also be composed of other layers. The preparation process of each layer is deposition, photolithography, etching, deposition of the cladding and smoothing the top of the cladding to the top of the GRIN layer. Subsequent layers will be deposited on the basis of the previous layer, photolithography, etching, and then cladding deposition and grinding according to requirements. The refractive index of each GRIN layer in a GRIN lens can be constant, or it can be changed by some rules. The layers are stacked to form GRIN components. This layer-by-layer manufacturing method can well control the ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com