Manufacturing methods of display base plate and display panel

A manufacturing method and array substrate technology, applied in nonlinear optics, instruments, optics, etc., can solve problems such as crosstalk and excessive leakage current, and achieve the effects of preventing crosstalk, reducing leakage current, and improving user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Embodiments of the present invention provide a method for manufacturing a display substrate and a method for manufacturing a display panel, which are used to solve the problems of excessive leakage current and crosstalk in thin film transistors caused by photo-alignment in the prior art, and improve the display quality of the panel user experience.

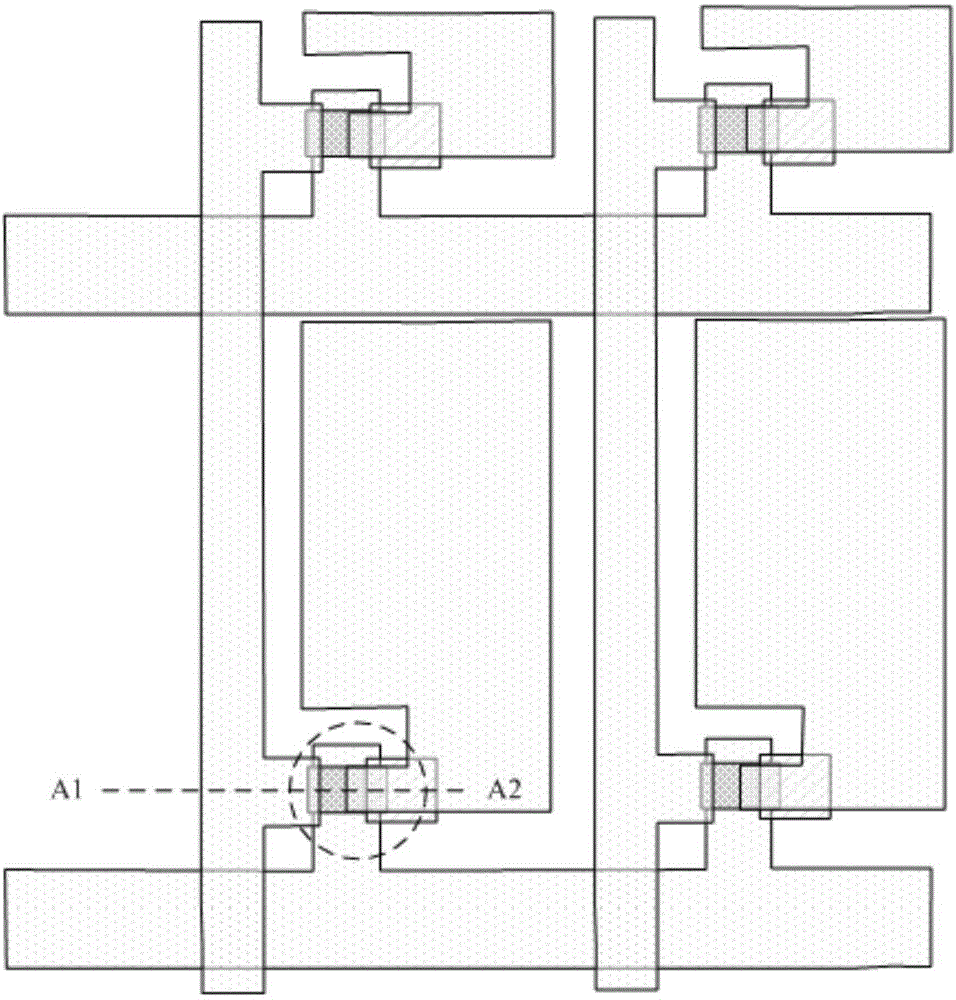

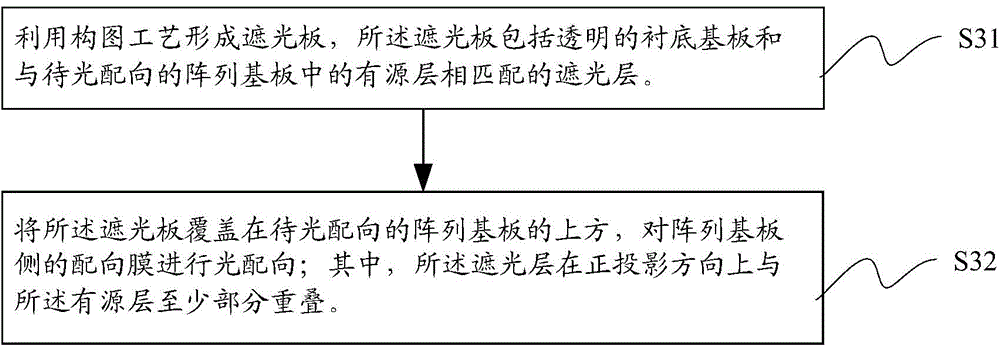

[0037] An embodiment of the present invention provides a method for manufacturing a display substrate, see image 3 , the method includes:

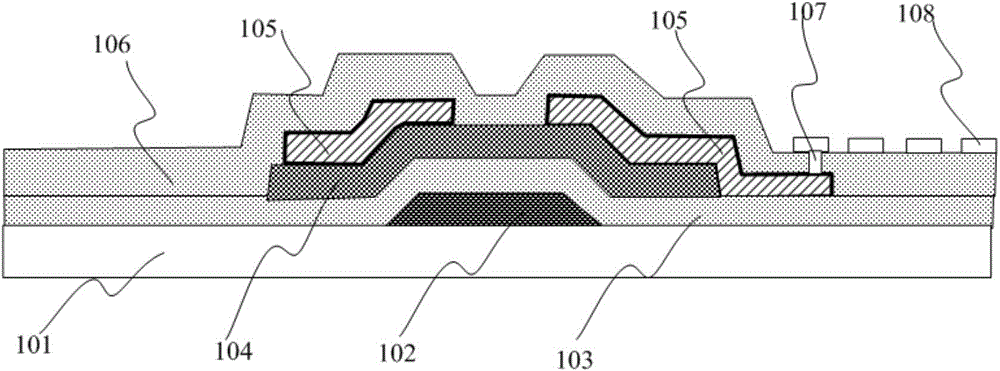

[0038] Step S31, see Figure 4 , using a patterning process to form a light-shielding plate, the light-shielding plate includes a transparent base substrate 41 and a light-shielding layer 42 matching the active layer in the array substrate to be photo-aligned.

[0039] Step S32, covering the light-shielding plate on the array substrate to be photo-aligned, and performing photo-alignment on the alignment film on the side of the array substrate; wherein, the light-shielding layer at le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com