High-temperature resistance rectangular electrical connector

An electric connector and high temperature resistant technology, which is applied in the direction of connection and connection device components, circuits, etc., can solve the problems of reducing signal transmission efficiency, rubber pad aging, carbonization, etc., and achieve high work safety and reliability, high temperature resistance performance Good, reasonable selection of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

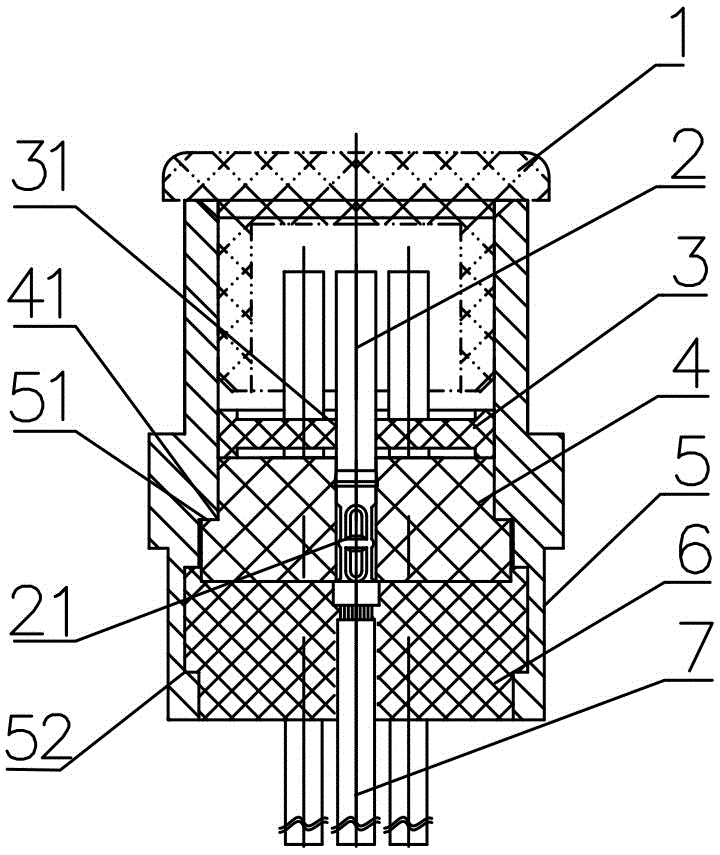

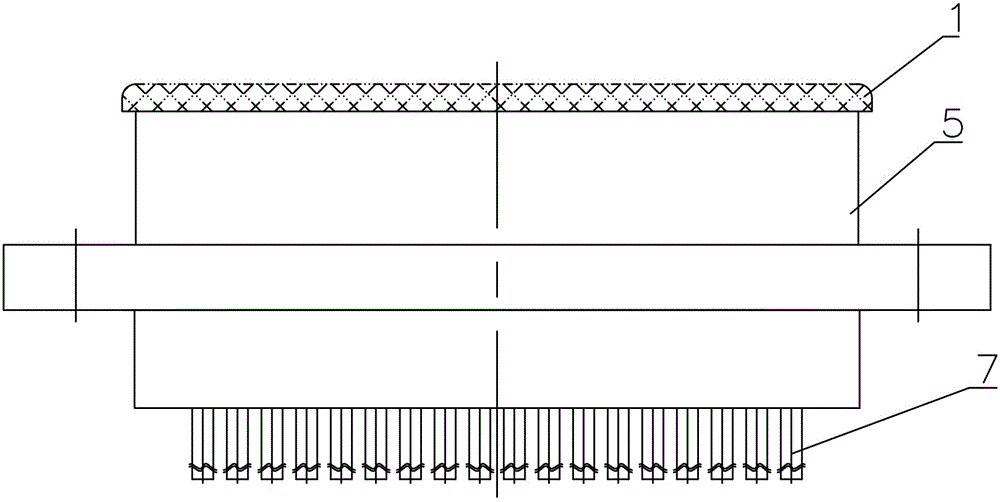

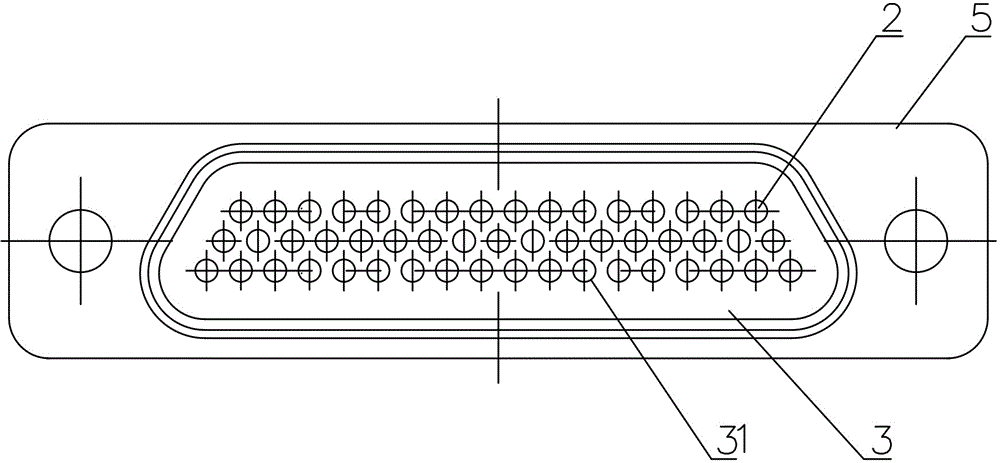

[0013] refer to Figure 1 to Figure 5 , the present invention includes an electrostatic dustproof cover 1, a contact piece 2, a rubber pad 3, a base 4, a casing 5, a potting glue 6 and a wire 7, the contact piece 2 is a rod member provided with a crimping cylinder 21, and the casing 5 is a rectangular shell provided with a base step 51 and a potting rubber ring groove 52, the rubber pad 3 is a plate-shaped body provided with a contact hole 31, and the outer side of the base 4 is provided with a notch 41; the contact The crimping barrel 21 of 2 is crimped with one end of the wire 7 to form a contact assembly 8, and then the contact assembly 8 is assembled to the corresponding position of the injection mold of the base, and the base 4 is formed into a base assembly 9 after injection molding. The base assembly 9 is loaded into the shell 5 from the tail end of the shell 5, and the notch 41 of the base 4 touches the base step 51 in the shell 5, and the potting glue 6 is poured into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com