Leakage protection socket

A leakage protection and socket technology, applied in the direction of circuits, electrical components, coupling devices, etc., can solve problems such as potential safety hazards, spring strain, and difficulty in ensuring the reliability of contact conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

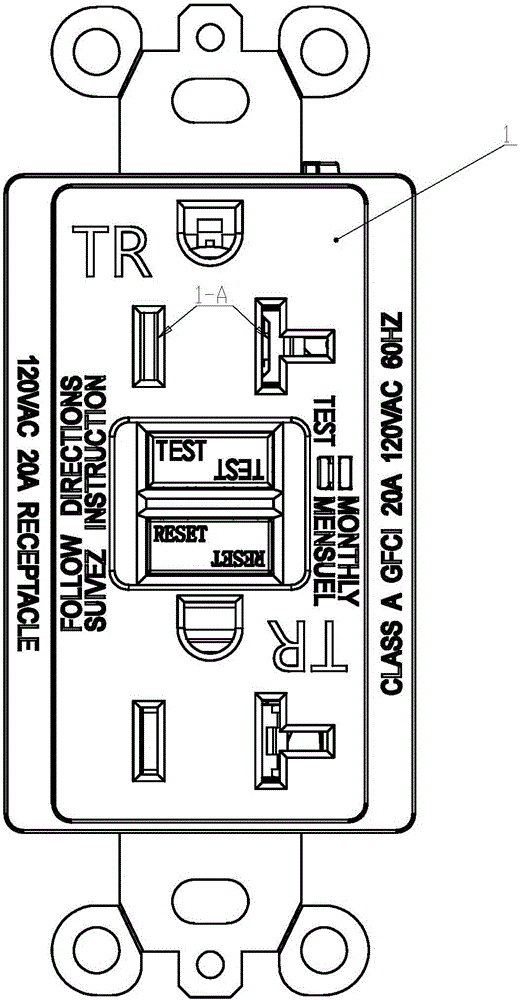

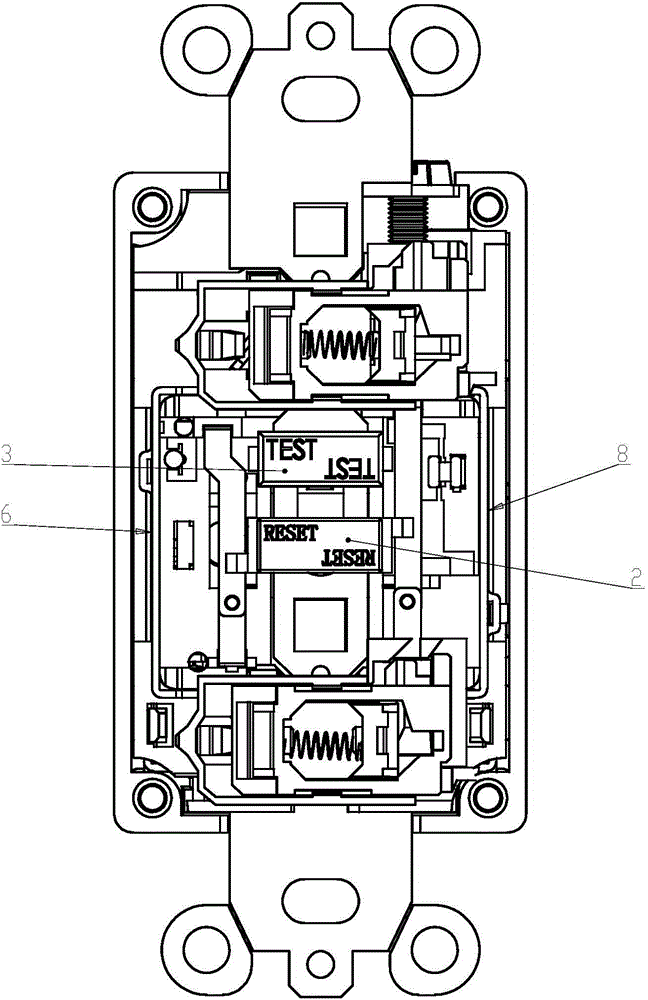

[0060] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6-A , Figure 6-B , Figure 6-C , Figure 7-A , Figure 7-B , Figure 7-C , Figure 8-A , Figure 8-B , Figure 8-C , Figure 9-A , Figure 9-B , Figure 9-C As shown, the leakage protection socket of the present invention includes a housing, output conductors (6, 8), power input terminals (9, 10), power output terminals (11, 12), and is used to drive the main circuit switch to close to make the power input terminal and the power supply output terminal and the output conductor to keep the reset button and the electromagnetic tripping mechanism used to disconnect the main circuit switch when leakage current is generated. The main circuit switch includes a pair of moving metal sheets (15, 16), and the moving metal The pieces (15, 16) are elastically installed in a clamping piece 17, and a positioning backing plate 18 is arranged under the clamping piece 17, and there is a mutual coop...

Embodiment 2

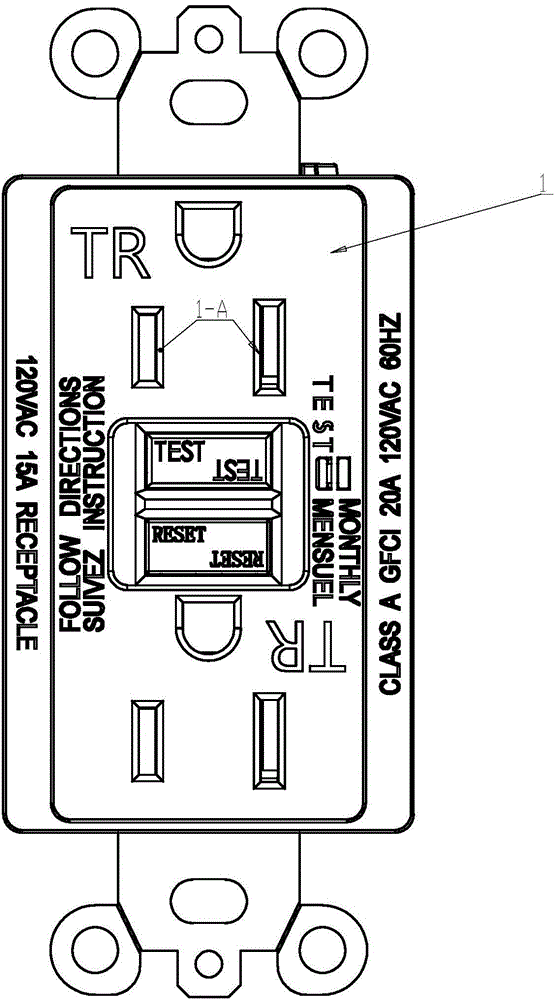

[0071] refer to Picture 1-1 , Figure 2-1 , Figure 3-1 , Pic 4-1 , Figure 5-1 , Figure 6-1-A , Figure 6-1-B , Figure 6-1-C , Figure 7-1-A , Figure 7-1-B , Figure 7-1-C , Figure 8-1-A , Figure 8-1-B , Figure 8-1-C , Figure 9-1-A , Figure 9-1-B , Figure 9-1-CAs shown, in this embodiment, the two output conductors (6, 8) respectively extend a static metal sheet integrally or separately to the inner side, and the static metal sheet has an output conductor static contact arranged side by side with the static contact end leading out of the output end of the power supply. On the side of the moving metal sheet close to the static contact end leading out of the power supply output, a pair of moving contact ends are provided to cooperate with the static contact end leading out of the power output end and the static contact end of the output conductor, and the other side of the moving metal sheet has a The static contact end of the power input end matches t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com