A method for preparing a composite jaw plate of a jaw crusher

A jaw crusher and jaw plate technology, applied in heat exchange equipment, rotors, cylinders, etc., can solve problems such as wear, poor surface wear resistance, uneven wear of jaw plates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation method of the jaw crusher composite jaw plate of the present invention comprises the following steps:

[0024] 1) Prepare the casting mold; when the prepared casting mold is used for pouring high manganese steel liquid, the casting mold is made of washed olivine sand with a mud content of less than 0.2% and used as a binder, and the addition amount is 4- 5% water glass mixed with CO 2 Hardened, and the surface of the mold cavity is coated with magnesia powder quick-drying paint; when the prepared mold is used for pouring molten alloy steel, the mold is made of water-washed quartz with a mud content of less than 0.2%. The sand is mixed with water glass used as a binder and added in an amount of 4-5%, and then subjected to CO 2 Hardened, and the cavity surface of the mold is coated with zircon powder quick-drying paint;

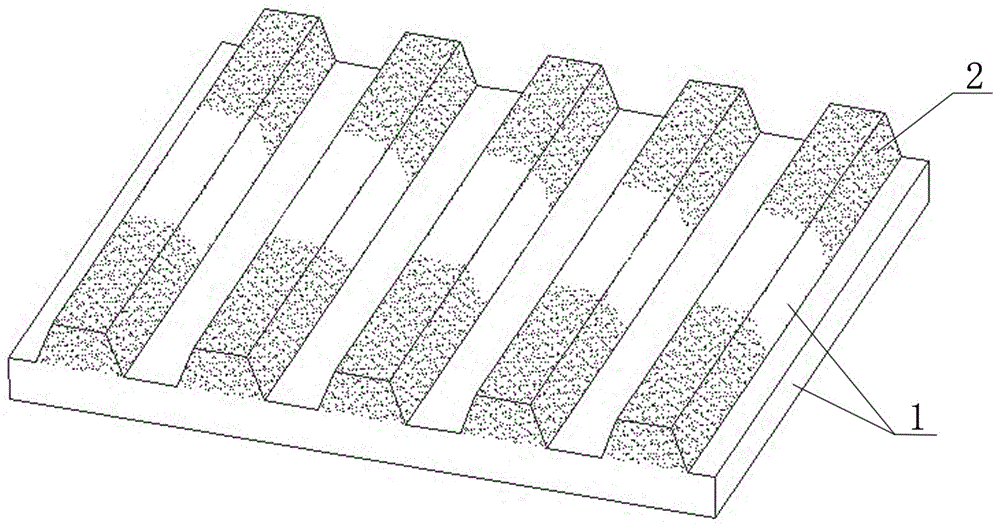

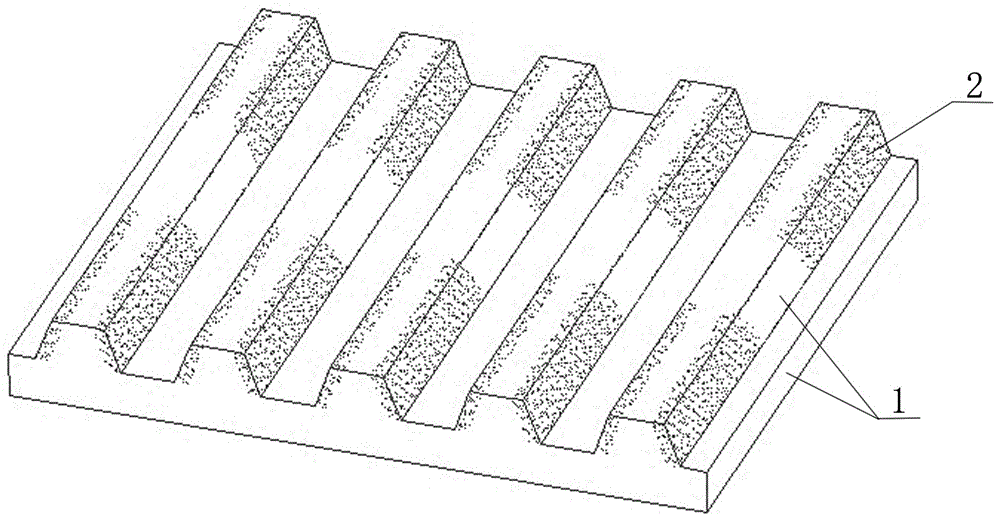

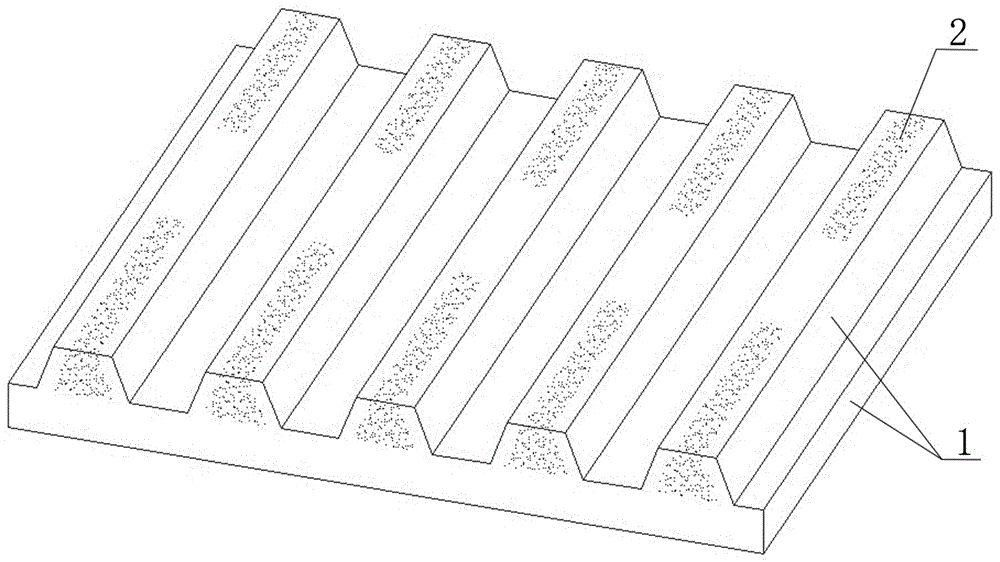

[0025] 2) Place the profiling reinforcement containing ceramic particles at the position corresponding to the wear area of the jaw p...

Embodiment 1

[0029] The base material is Mn13 type high manganese steel, the composition is (percentage by weight) C: 1.2%, Cr: 1.8%, Si: 0.6%, Mn: 12%, S≤0.04%, P≤0.04%, and the rest is Fe; Type preparation: use washed olivine sand with a mud content of 0.15%; water glass as a binder with an addition of 4.5%; CO 2 Hardening; the surface of the mold cavity is painted with magnesia powder quick-drying paint. Preparation of Contoured Reinforcement Containing Ceramic Particles: Al 2 o 3 -ZrO 2 The composite ceramic particles are mixed with the binder and placed in the mold, and solidified into a profiling shape that is resistant to the erosion of molten metal and has three-dimensional intercommunication and multi-dimensionality between the ceramic particles and the shape of the jaw plate. The profiling reinforcement containing ceramic particles is placed in the corresponding position of the wear area of the jaw plate in the mold. The final wear surface of the ceramics does not exceed the...

Embodiment 2

[0031] The base material is Mn18 type high manganese steel, the composition is (percentage by weight) C: 1.25%, Cr: 2.1%, Si: 0.6%, Mn: 18%, S≤0.04%, P≤0.04%, and the rest is Fe; Type preparation: use washed olivine sand with a mud content of 0.15%; water glass as a binder with an addition of 4.5%; CO 2 Hardening; the surface of the mold cavity is painted with magnesia powder quick-drying paint. Preparation of Contoured Reinforcement Containing Ceramic Particles: Al 2 o 3 -ZrO 2 The composite ceramic particles are mixed with the binder and placed in the mold, and solidified into a profiling shape that is resistant to the erosion of molten metal and has three-dimensional intercommunication and multi-dimensionality between the ceramic particles and the shape of the jaw plate. The profiling reinforcement containing ceramic particles is placed in the corresponding position of the wear area of the jaw plate in the mold. The final wear surface of the ceramics does not exceed th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com