A method of aluminium slag reduction to obtain metal aluminium

A technology of metal aluminum and aluminum slag, applied in the field of reducing metal aluminum, can solve the problems of long reaction time, increased cost, lengthy process, etc., and achieve the effects of short reaction time, cost saving and output time saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

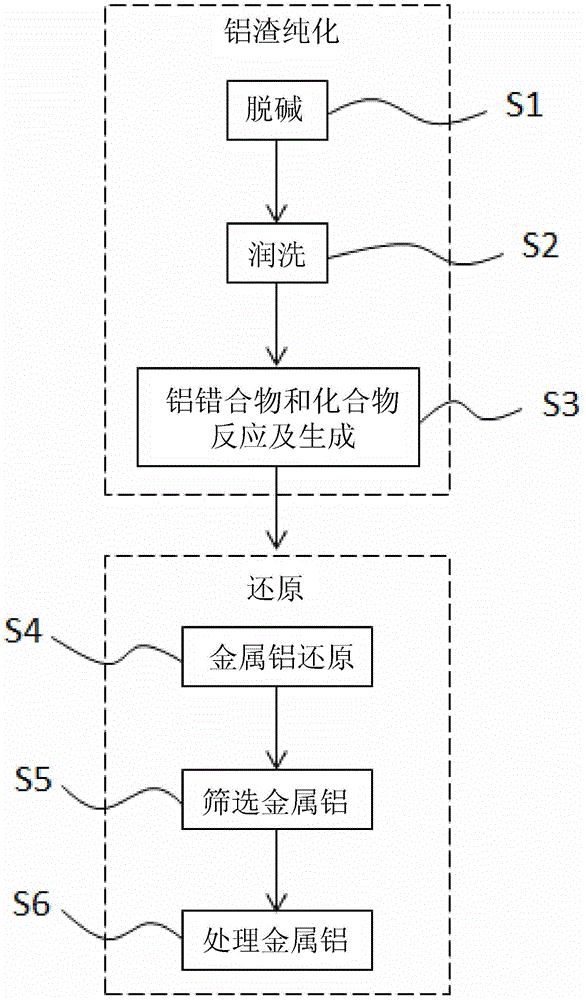

[0019] figure 1 It is a flowchart showing the method of reducing metallic aluminum from aluminum slag according to the present invention.

[0020] Please refer to figure 1 , the steps of the method for reducing metal aluminum from aluminum slag of the present invention are: comprising an aluminum slag purification step and a reduction step.

[0021] The aluminum slag purification step includes a dealkalization step S1, a rinsing step S2, and a reaction and generation step S3 of aluminum complexes and compounds.

[0022] Dealkalization step S1 is to put 1Kg of primary and secondary aluminum slag into methanol-n / ethanol-m mixed solution, methanol with a purity of more than 95% or ethanol with a purity of more than 95% for dealkalization. Next reaction, the reaction time is controlled within 10-15 minutes to produce dealkalized primary and secondary aluminum slag; wherein, the n:m ratio of methanol-n / ethanol-m mixed solution can be 1:1, 1: 2. 1:4 or 1:8.

[0023] Rinsing step...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap