Construction method of curved-surface arc-shaped main towers of cross-river single-cable suspension bridge

A construction method and suspension bridge technology, applied in suspension bridges, bridge forms, bridges, etc., can solve the problems of broken natural river environment, high safety risks, high costs, etc., to simplify tower body deviation data, save hoisting costs, and avoid personal injury. The effect of security risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

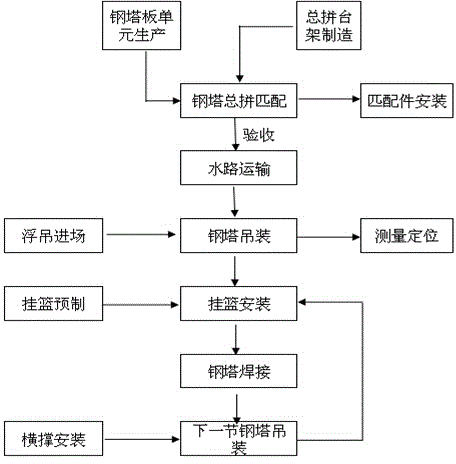

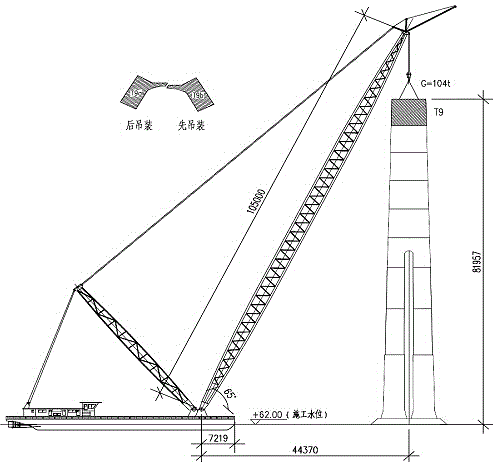

[0039] In order to ensure that the source of the installation line is controllable, a 1:1 positioning bench is used during manufacturing in the factory, and the steel tower body is assembled horizontally as a whole, and the tower can be transported to the bridge site after passing the acceptance and meeting the design requirements. When measuring and positioning the steel tower, the conventional construction adopts the geodetic coordinate system for stakeout. The data of this measurement method is long, and the indication deviation data is related to the position of the instrument station, which increases the difficulty of high-altitude positioning and measurement of the steel tower. By adopting four-parameter calculations, the geodetic coordinate system is converted into an independent coordinate system, the measurement data of the steel tower is simplified, the measurement deviation direction of the tower body is clarified, and the steel body can be quickly adjusted. The hois...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com