Construction method novel vertical shaft horizontal rotation jet grouting pile foundation pit lateral wall water stopping curtain

A technology of horizontal jet grouting piles and water-stop curtains, which can be used in shaft equipment, infrastructure engineering, and sinking, and can solve problems such as uneconomical and waste of water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

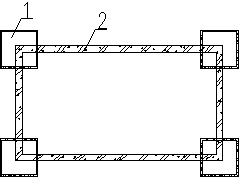

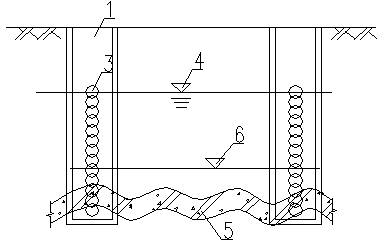

[0029] Such as figure 1 , figure 2 As shown, the vertical shaft 1 is set around the foundation pit. The size of the vertical shaft 1 should meet the minimum size requirements of the construction horizontal jet grouting pile. The size of the vertical shaft is a square with a side length of 4000mm. Carry out horizontal jet grouting pile construction along the side of the foundation pit, and construct horizontal jet grouting piles 3 downward from a position slightly higher than the groundwater level 4 to form an improved body of the side wall of the foundation pit, and the improved bodies are formed after overlapping in the horizontal direction One layer of horizontal artificial water-resisting layer is used as the water-stop curtain 2 on the side wall of the foundation pit. The water-stop curtain and the base horizontal water-resisting layer 5 form a fully enclosed water-stop system in the foundation pit.

[0030] The horizontal rotary grouting pile forms a fully enclosed wa...

Embodiment 2

[0042]The size of the shaft involved is a square with a side length of 5000 mm, and the depth of the shaft should reach 1500 mm below the horizontal water-resisting layer of the base, and the rest of the technical features are the same as in Embodiment 1.

Embodiment 3

[0044] The size of the shaft involved is a square with a side length of 4500 mm, and the depth of the shaft should reach 1200 mm below the horizontal water-resisting layer of the base, and the rest of the technical features are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Side length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com