A hydraulic system of a dual-purpose excavator

The technology of a hydraulic system and a shovel, which is applied to the field of the hydraulic system of a dual-purpose shovel, can solve the problems of increasing production auxiliary time, difficult to move the excavator, uneven distribution of force, etc., so as to save equipment investment costs and protect Not damaged by high temperature, reducing the effect of overall quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

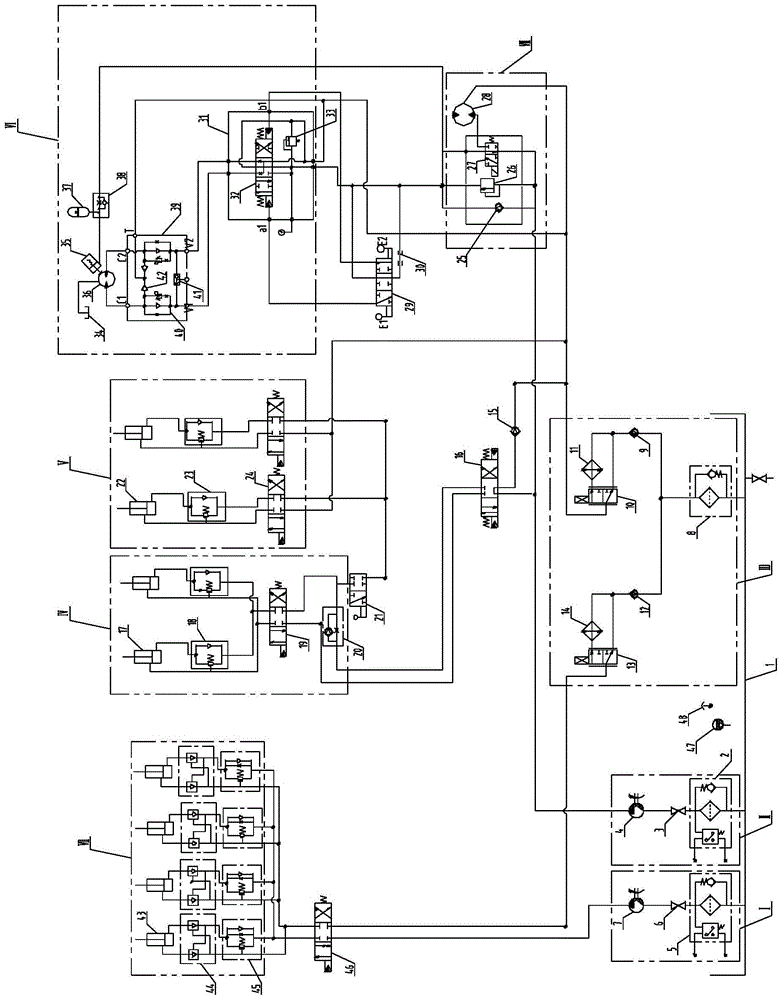

[0026] See figure 1 , is a schematic diagram of the hydraulic system of the present invention, a hydraulic system of a dual-purpose excavator in the present invention, including a hydraulic oil tank 1, an oil supply system, an oil return system III, a luffing system IV, a telescopic system V, and a rotary system VI , air-conditioning system VIII and support system VII, the luffing system IV, telescopic system V, rotary system VI, air-conditioning system VIII and support system VII are respectively connected to the hydraulic oil tank 1 through the oil supply system and the oil return system III, and form respective hydraulic circuit.

[0027] The oil supply system is composed of an oil supply system I and an oil supply system II II. The oil supply system I and the oil supply system II are both connected by an electromagnetic filter and a stop valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com