Horizontal frame and vertical frame connection structure of T-shaped steel joist

A technology for connecting structures and T-shaped steels, applied in building components, building structures, walls, etc., can solve problems such as inability to meet engineering requirements, large deformation wind loads, location strength, etc., to achieve disorderly installation operations, and reliable keel connection. , Reasonable effect of structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

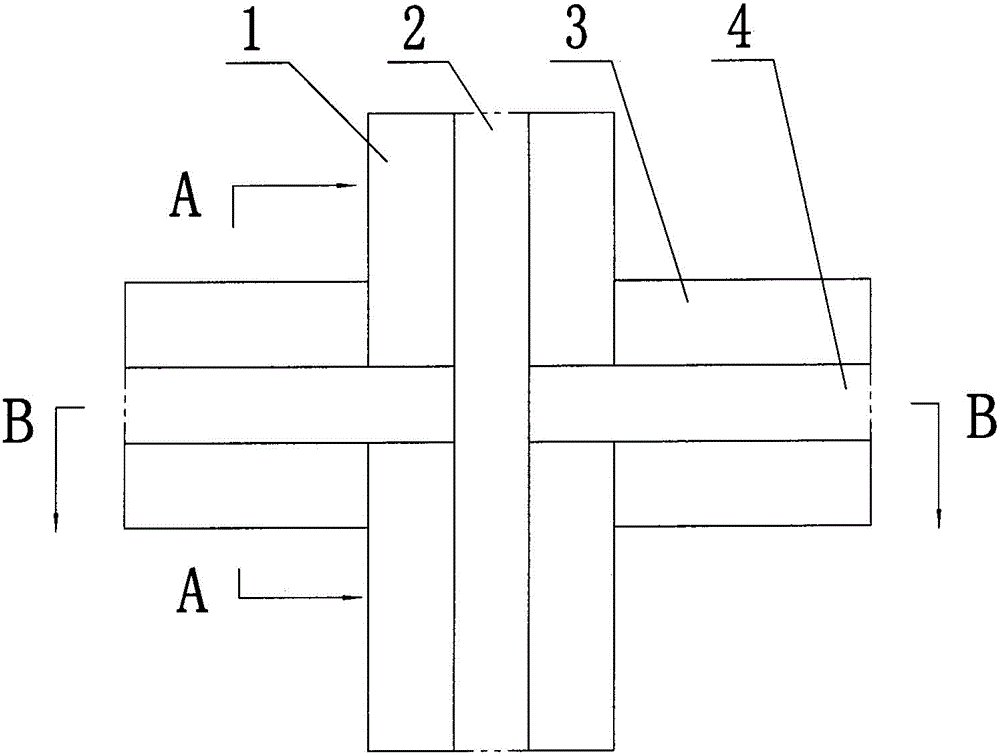

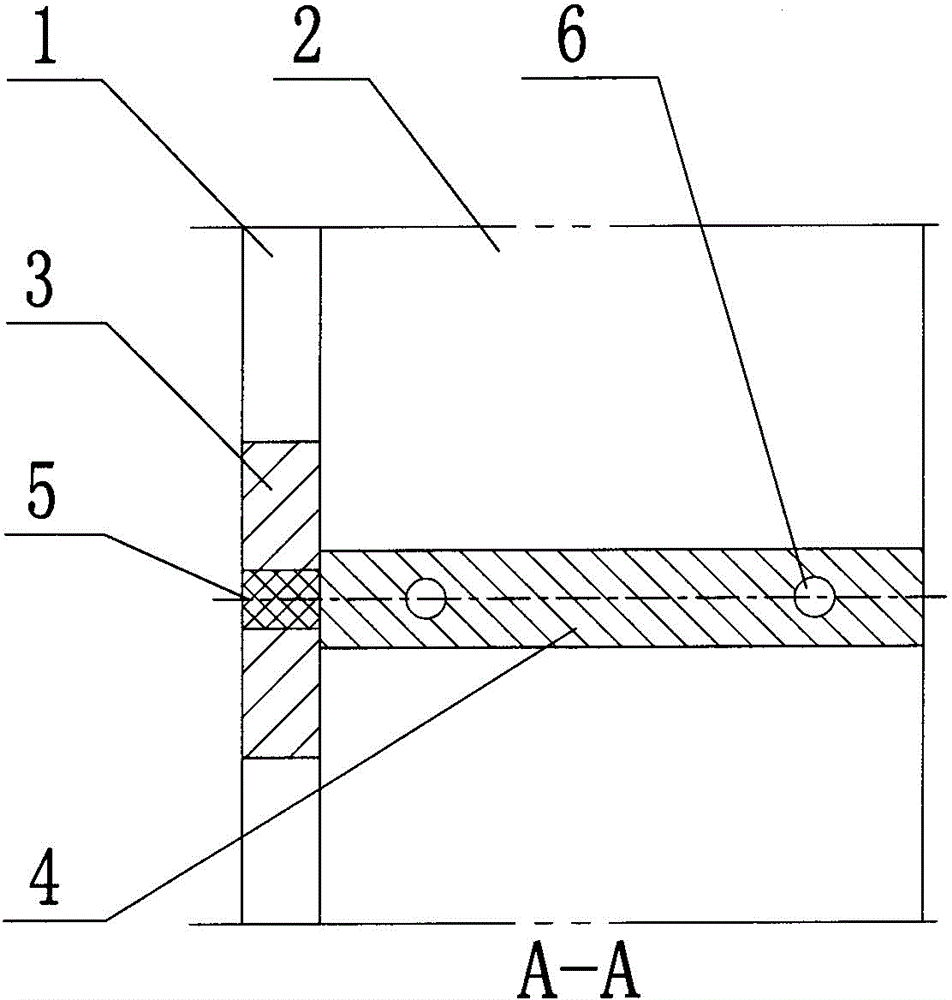

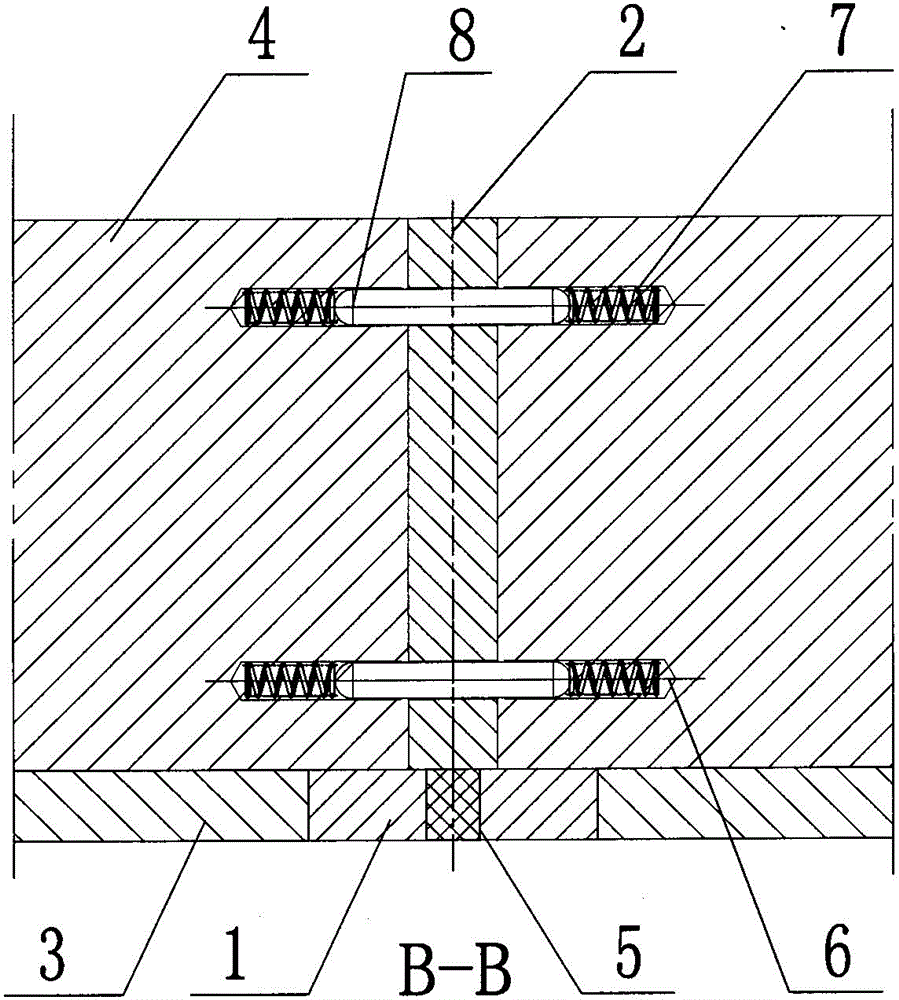

[0020] according to Figure 1-8 The specific structure of the present invention will be described in detail. The T-shaped steel keel horizontal and vertical frame connection structure includes a T-shaped steel keel horizontal frame connected by a horizontal frame end plate 3 and a horizontal frame rib 4, and a T-shaped steel keel connected by a mullion end plate 1 and a mullion rib 2. Mullion, and parts such as the pin 6 that connects T-shaped steel keel horizontal, mullion rib plate 4,2. Among them, the profiles of mullion end plate 1, mullion rib plate 2, horizontal frame end plate 3, and transverse frame rib plate 4 of the T-shaped steel keel are all made of cold-rolled steel plates with good appearance quality and good straightness. In this embodiment, The profile is made of Q235 cold-rolled steel plate. In order to ensure the corrosion resistance of the profile, the cold-rolled steel plate is degreased, derusted, and deburred, and the surface is treated with fluorocarbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com