Boiler flue gas treatment device for oil refinery

A boiler flue gas and treatment device technology, applied in the direction of greenhouse gas reduction, climate sustainability, combustion technology mitigation, etc., can solve the problem that the heat of the main flue is not fully utilized, the heat of the flue gas cannot be effectively used, and the heat is not well The removal and other problems, to achieve the effect of easy promotion and use, safe use and simple results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

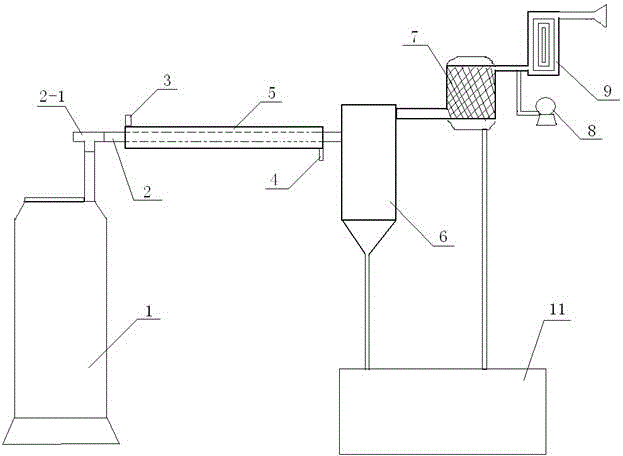

[0018] In this example, if figure 1 As shown, a refinery boiler flue gas treatment device includes a chimney cover 1, a water jacket 5, a cyclone 6, a filter screen 7, an exhaust fan 8, an activated carbon filter 9, and a slag collector 11. The chimney cover 1 is connected to the cyclone 6 through the pipeline 2, the cyclone 6, the filter 7, the exhaust fan 8, and the activated carbon filter 9 are connected in sequence, and the bottoms of the cyclone 6 and the filter 7 are respectively connected to the slag collector 11. The pipeline 2 is provided with a three-way connector 2-1. The water jacket 5 is provided with a water inlet 4 and a water outlet 3, the water inlet 4 is located at one end of the cyclone 6, and the water outlet 3 is located at one end of the chimney cover 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com