Detection device for detecting tightness of freezing pipe

A technology of detection device and freezing tube, which is applied in the direction of measuring the acceleration and deceleration rate of fluid and using liquid/vacuum degree for liquid tightness measurement, etc., can solve the problems of low construction efficiency, inconvenient construction, easy leakage, etc. The effect of improving work efficiency, reducing work difficulty, and reducing labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

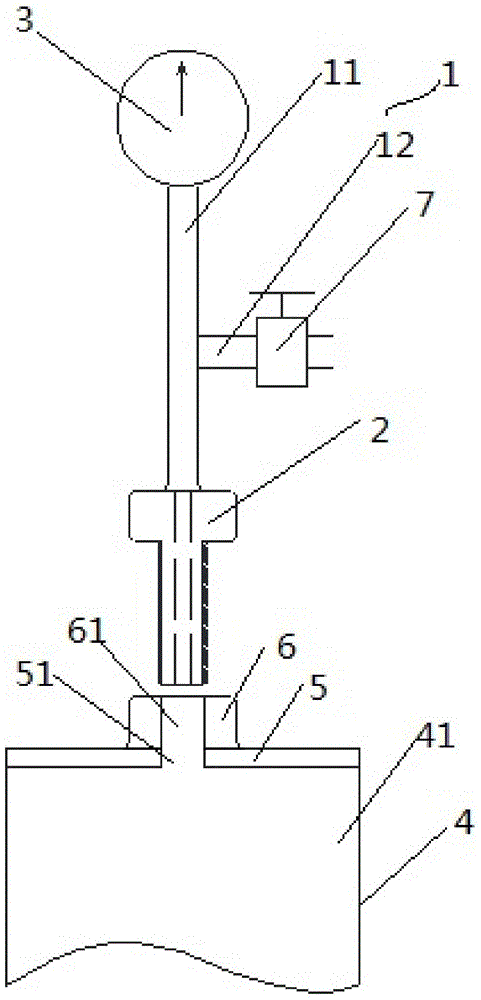

[0026] like figure 1 As shown, a detection device for detecting the tightness of the freezing tube 4 includes a pressure pipeline 1, one end of the pressure pipeline 1 is connected to the pressure equipment, and the other end of the pressure pipeline 1 is connected to the first connector 2 ;

[0027] The pressure detection device 3 for detecting the pressure of the medium in the pressure pipeline 1 is installed on the pressure pipeline 1;

[0028] The freezing tube 4 has a medium containing cavity 41, the medium containing cavity 41 communicates with the outside world through the opening provided on the freezing tube 4, the first connecting head 2 is connected to the opening in a sealed and movable manner, and the sealed and movable connection can be The connection method of threaded sealing connection or flange connection or other sealing connection methods is adopted, as long as the first connecting head 2 can be sealed with the opening, the first connecting head 2 is a hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com