Diving slamming experimentation device for ocean structure

A technology for marine structures and experimental devices, which is applied to measurement devices, machine/structural component testing, impact testing, etc., can solve the problems of a single working mode of the load-throwing mechanism, increase the experimental cost, etc., and achieve good practicability and market value. , easy to create and operate, easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

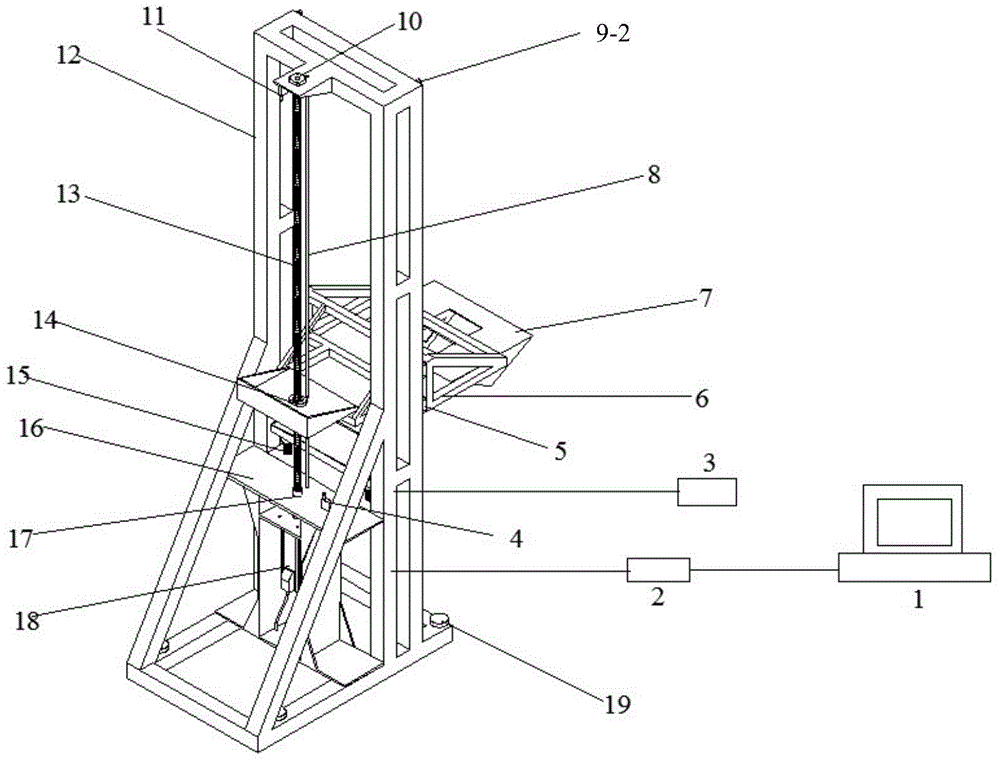

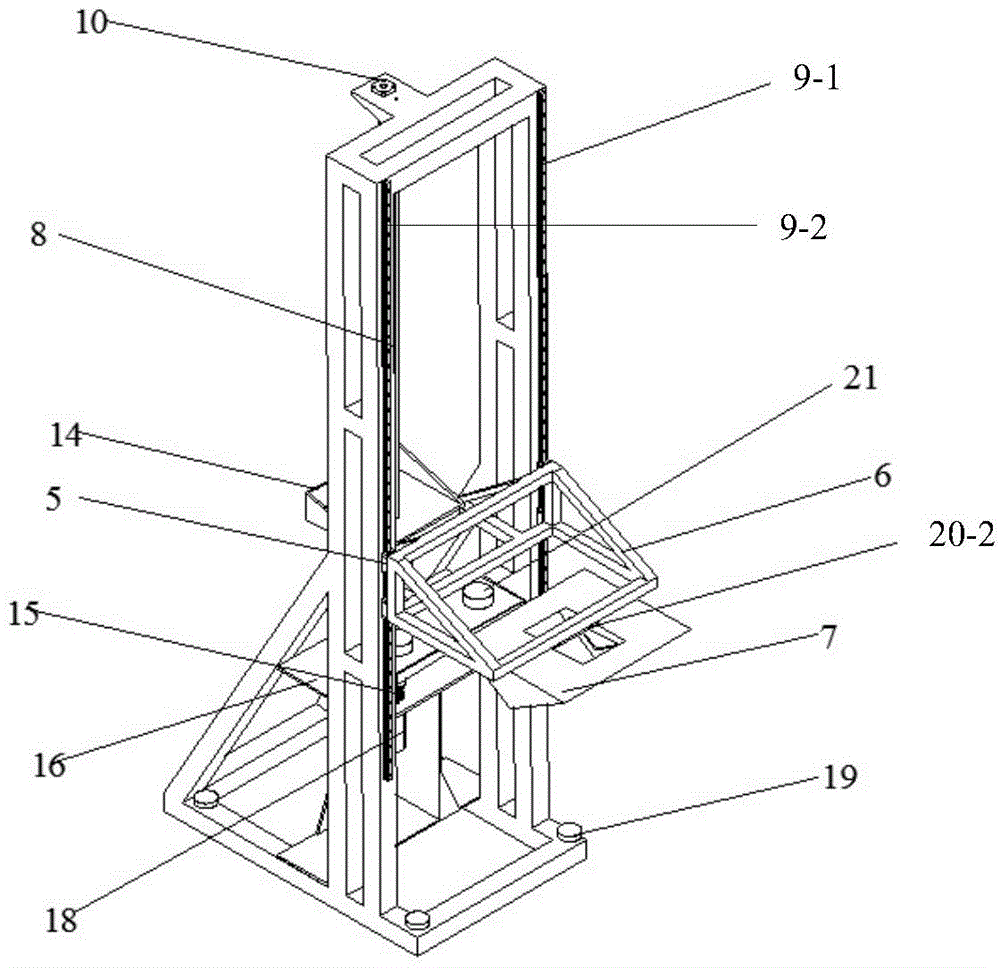

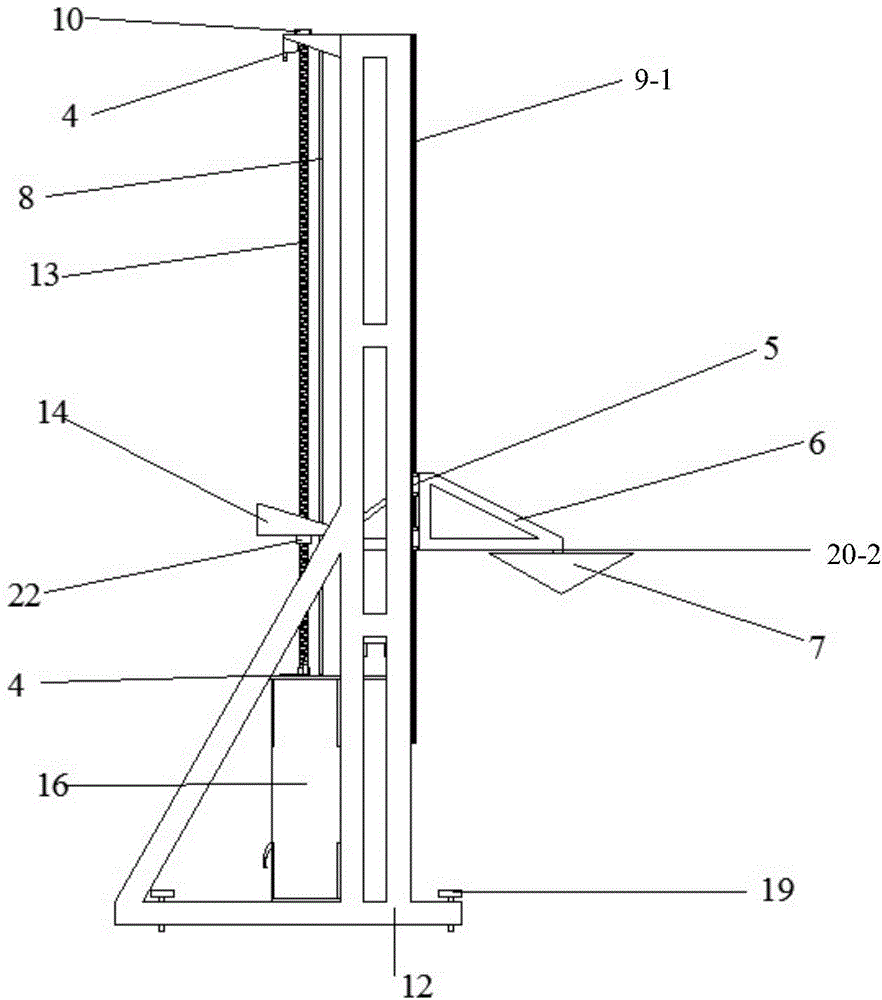

[0019] Implementation Case 1: Combining Figure 1 to Figure 3 , Figure 5 to Figure 8 , the present invention includes a base 12, a structure 7, a motor base 16 installed in the middle of the base 12, a motor 18 installed at the lower end of the motor base 16, a lead screw 13 connected to the output shaft of the motor 18, and a screw 13 sleeved on the wire The first-level throwing slide frame 14 on the bar 13, two vertical guide rails 9-1 and 9-2 installed on both sides of the base 12, symmetrically installed on the two vertical guide rails 9-1 and 9-2 Four slide blocks 5 and the secondary dumping slide frame 6 that are fixedly installed on the four slide blocks 5, the said primary dumping slide frame 14 is sleeved on the lead screw 13 means that the primary dumping slide frame 14 is set by The lead screw nut 22 is sleeved on the lead screw 13, the first electromagnet 20-1 is arranged on the first-stage dumping carriage 14, the second electromagnet 20-2 is arranged on the sec...

Embodiment example 2

[0020] Implementation Case 2: Based on the above-mentioned embodiment combined with Figure 4 , the present invention can also be: also include a buffer system, the buffer system includes a buffer base 24, a spring shock absorber 15, a buffer platform 23 and a rubber block 21, wherein the buffer base 24 is welded to the vertical frame of the base 12 In 31, it is flat with the top plate of the motor base 16, and the spring shock absorber 15 is installed on the buffer base 24, which is connected with the buffer platform 23, and the rubber block 21 is bonded to the buffer platform 23 by resin, That is to say, a buffer base 24 is also installed on the base 12, and the buffer base 24 and the motor base 16 are symmetrically located at the same horizontal position at the two ends of the base 12, and the four corners of the buffer base 24 are respectively Spring shock absorbers 15 are provided, and buffer platforms 23 are installed on the upper surfaces of the four spring shock absorb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com