Marking method for background noise difference removal in laser Raman gas analysis system

A Raman gas and analysis system technology, applied in the direction of material excitation analysis, Raman scattering, etc., can solve the problems of not achieving the ideal effect, achieve the effect of improving the accuracy of calibration, improving the accuracy of measurement, and easy to achieve

Inactive Publication Date: 2015-06-10

WUHAN CUBIC OPTOELECTRONICS

View PDF5 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The above methods can effectively remove the interference of its noise and fluorescence in some cases, but in a complex system, these methods are powerless for the Raman spectrum interference of other non-detecting substances. When faced with high-intensity fluorescence background interference also can not achieve the desired effect

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

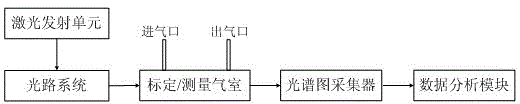

[0025] Such as figure 1 As shown, a calibration method for differentially removing background noise in a laser Raman gas analysis system, the specific steps are as follows:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a marking method for background noise difference removal in a laser Raman gas analysis system. The marking method is based on a Raman scattering spectrogram of marked gases and an intermediate carrier gas and comprises the steps that firstly, the influence of ground noise of the system is eliminated, so that a Raman scattering spectrogram of the marked gases and the intermediate carrier gas without background noise is obtained; a marking constant is obtained through data processing on information obtained from the spectrogram, and according to the physical characteristics of the gas, the marking constant is not influenced by the temperature, the pressure, the environment and other factors; in this way, all known gases can be marked relative to the intermediate carrier gas, and a marking database of all the gases relative to the intermediate carrier gas is established. The marking method is used for marking in the laser Raman gas analysis system, effective Raman information can be effectively extracted from complicated background noise, the marking precision is greatly improved, and therefore the measuring precision of the system is improved; besides, the marking method is simple and easy to implement.

Description

technical field [0001] The invention relates to a calibration method for a laser Raman gas analysis system, in particular to a calibration method for differentially removing background noise in a laser Raman gas analysis system. Background technique [0002] Scattering occurs when light hits a substance. When scattering occurs, the wavelength of most of the scattered light does not change, and this kind of scattering without changing wavelength is called Rayleigh scattering; the wavelength of a small part of scattered light will increase or decrease, and this kind of scattering with changing wavelength It is called Raman scattering, and its corresponding spectrum is called Raman spectrum. [0003] The Raman spectrum is the basis for analyzing substances using Raman spectroscopy. The fixed-wavelength laser Raman scattering technology is one of the most advanced gas measurement technologies. It has developed rapidly in recent years and is considered to be a revolutionary chan...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N21/65

Inventor 熊友辉刘志强江坤田蕾石平静

Owner WUHAN CUBIC OPTOELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com