Evaluation method of absolute oil accumulated transformation rate

A conversion rate and crude oil technology, which is applied in the evaluation field of cumulative conversion rate of net oil, can solve the problems of ineffective utilization, difficult definition of primary cracking and secondary cracking, expensive experiment costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the drawings and embodiments.

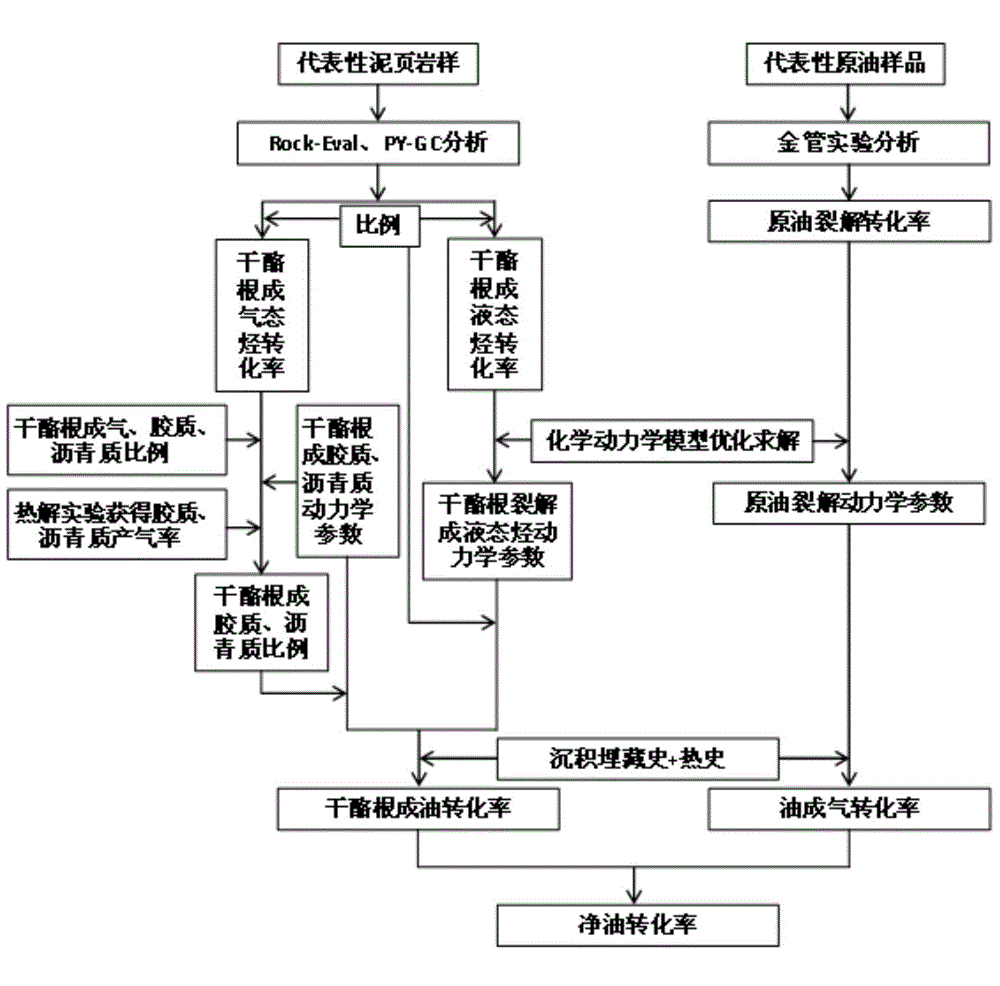

[0035] Such as figure 1 As shown, the evaluation method of net oil cumulative conversion rate proposed by the present invention includes the following steps:

[0036] 1) Carry out thermal simulation experiments, including the Rock-Eval (rock pyrolysis) experiment of the open system, the PY-GC experiment and the gold tube experiment of the closed system:

[0037] ①Select representative shale samples

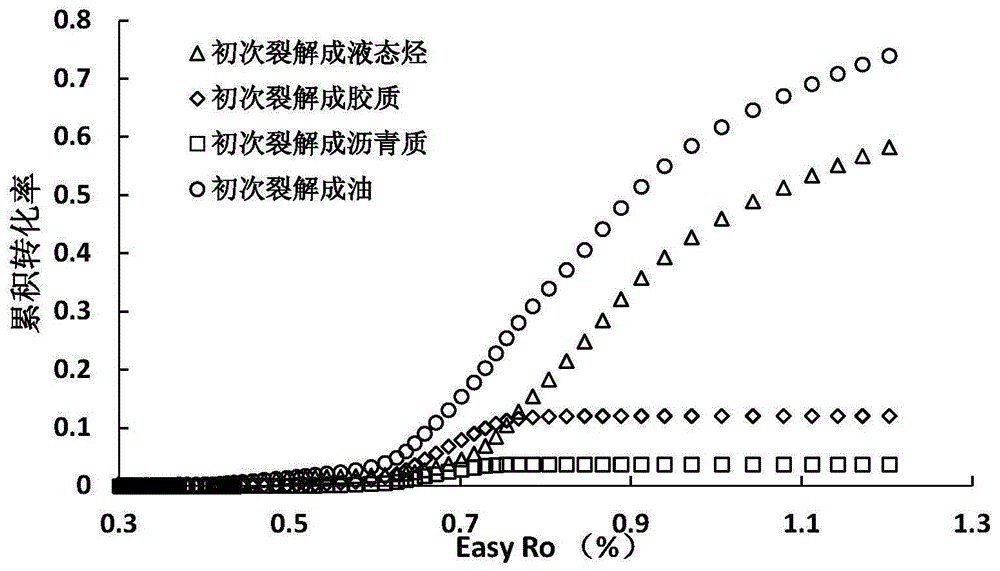

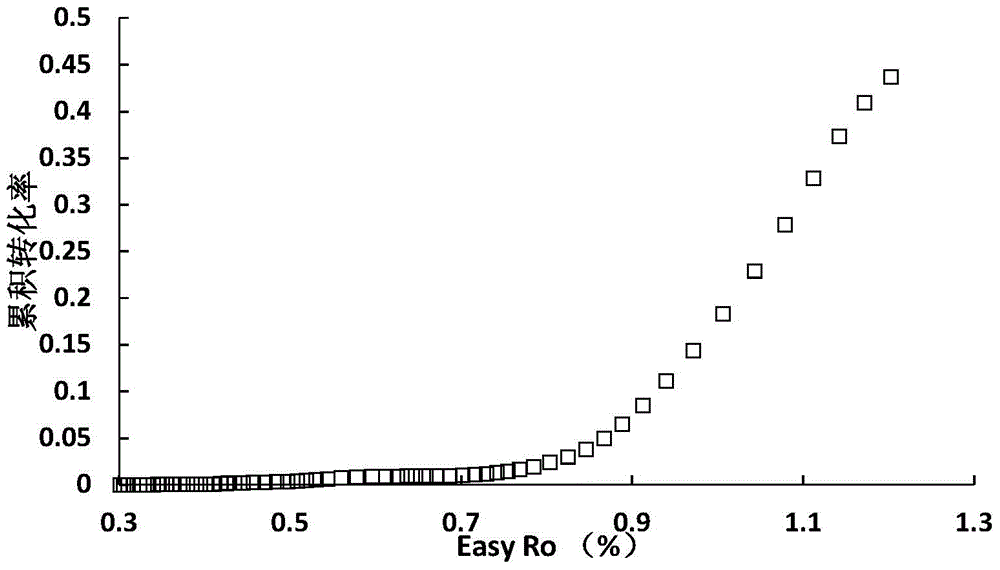

[0038] Take Well An17 in Damintun Sag, Liaohe Depression as an example, extract shale samples from this well, and then perform Rock-Eval and PY-GC experiments on the shale samples to detect cheese in the shale samples The oil and gas products generated by the initial cracking of roots, and then the cumulative conversion rate of kerogen cracking into liquid hydrocarbons and gaseous hydrocarbons at different temperatures (as shown in Table 1 and Table 2), where C 1 -C 5 Is gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com