Multifunctional automatic drilling and riveting end executor and automatic drilling and riveting method

An end effector, automatic drilling and riveting technology, applied in the direction of instruments, digital control, control/adjustment systems, etc., can solve the problems of high labor intensity, unfavorable production efficiency, and the inability to fully utilize the advantages of automatic hole making and countersinking, etc., to achieve automation The effect of high degree and work efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

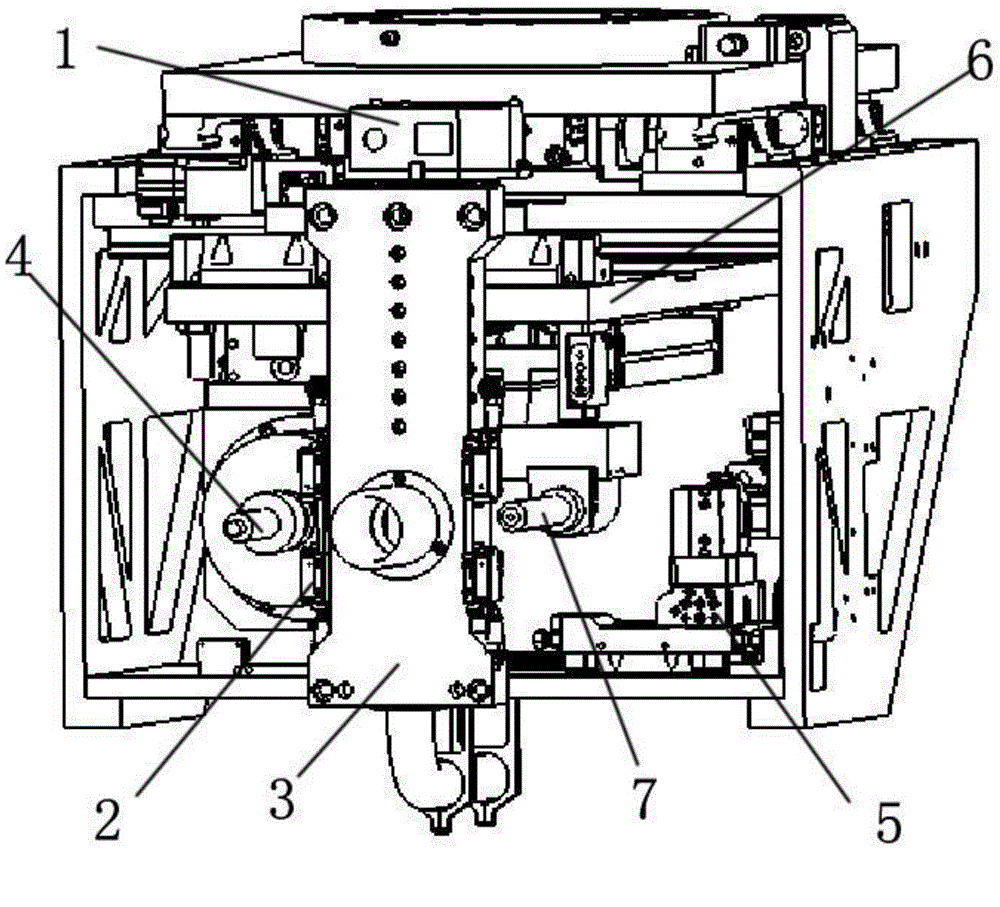

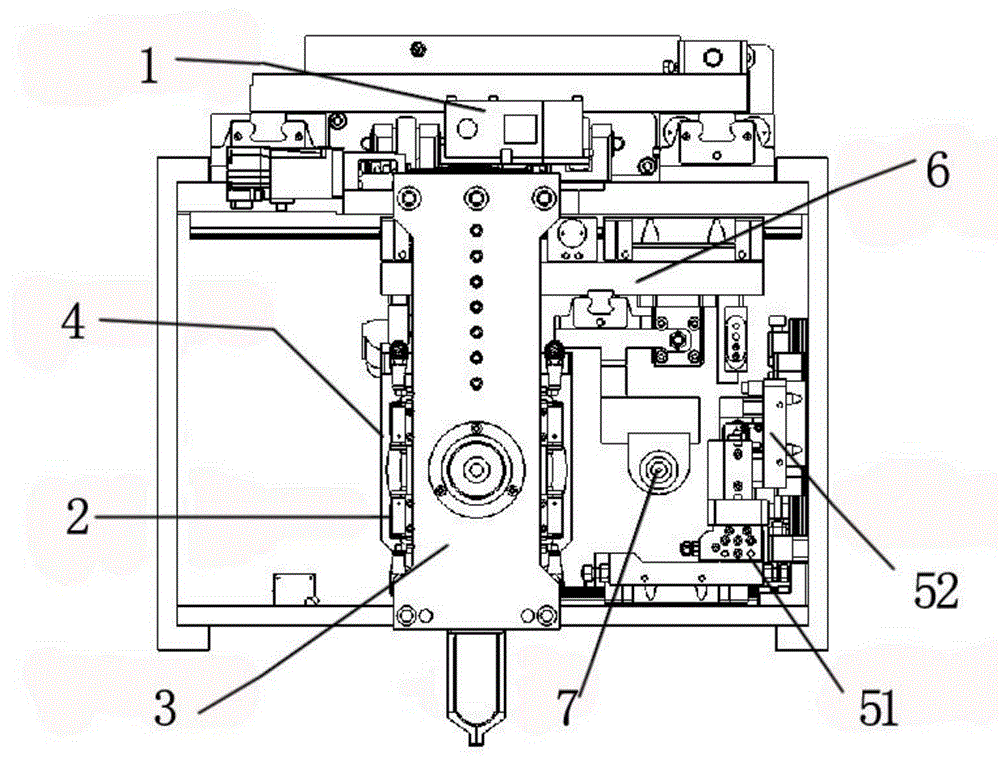

[0032] The multifunctional automatic drilling and riveting end effector and the automatic drilling and riveting method of the present invention are described in detail with reference to the accompanying drawings.

[0033] like figure 1 , 2 The multifunctional automatic drilling and riveting end effector shown is controlled by the control system, with the machine tool or robot as the carrier, and integrates the reference hole detection module, normal alignment module, pressure foot module, hole making and spotting module, rivet receiving and testing Module, station conversion module, riveting module, each module includes two parts: control circuit and actuator, the control circuit controls the actuator, and the control system communicates with the control circuit of each module;

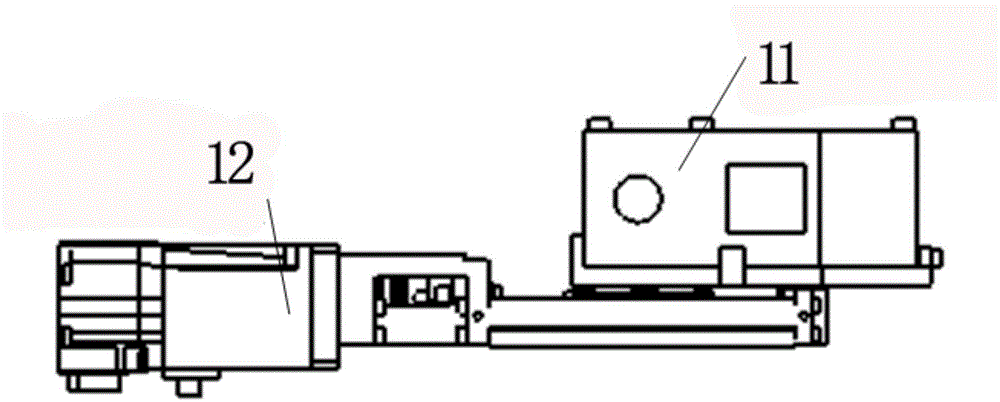

[0034] Among them: the actuator of the reference hole detection module includes a 2D laser profiler 11, a linear servo slide, and a grating ruler. The linear servo slide is driven by a servo motor 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com