Rapid-forming automatic powder spreading quantity adjusting closed-loop control system and method

A closed-loop control and automatic adjustment technology, applied in general control systems, control/adjustment systems, program control, etc., can solve problems affecting the optimization and adjustment of high-energy beam selective melting process, part forming failure, powder waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

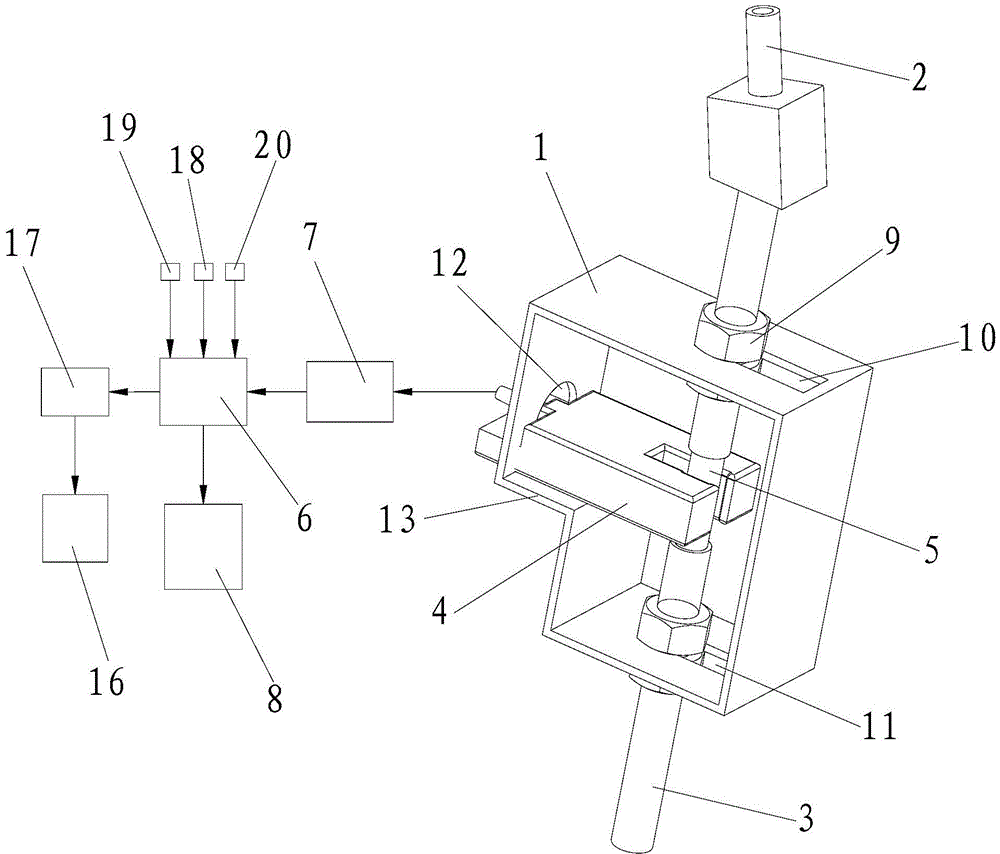

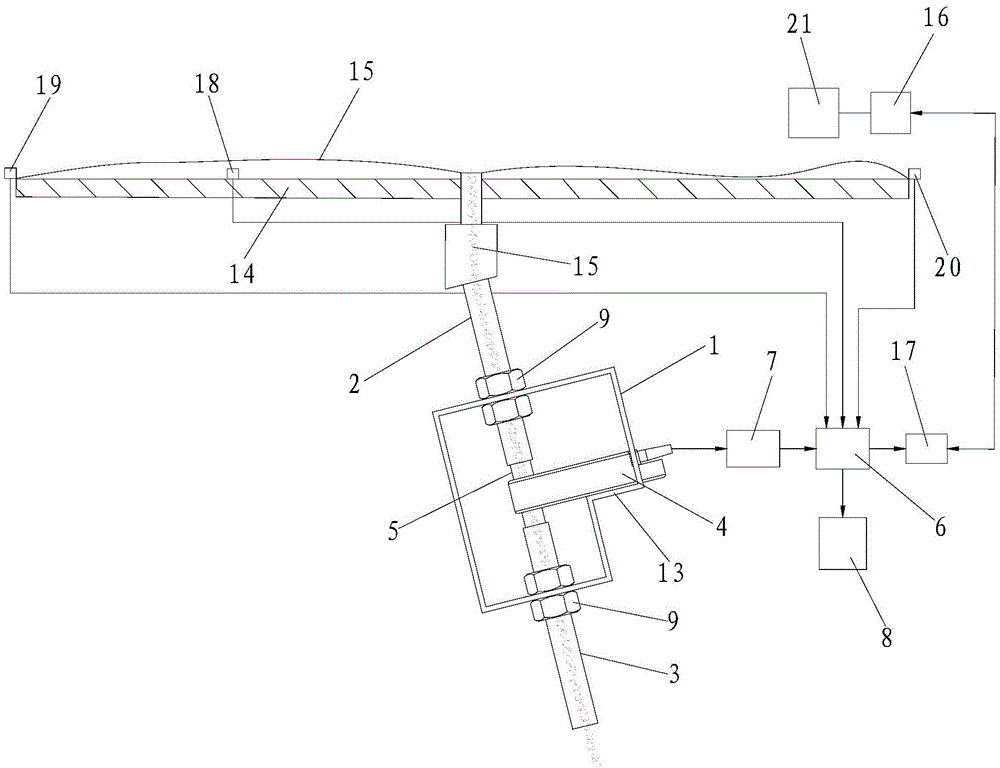

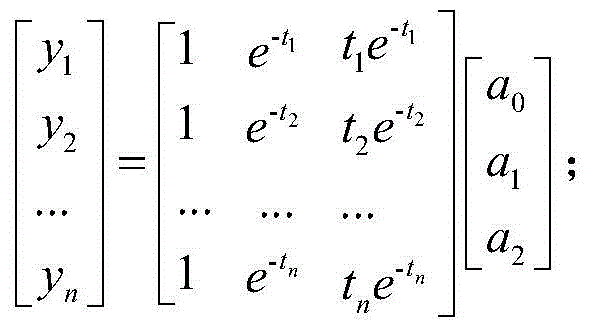

[0044] Such as figure 1 As shown, the present invention includes a powder spreading time detection mechanism, a powder spreading controller 6 and a computer 8 connected with the powder spreading controller 6, and a servo motor 16 for driving the powder spreading mechanism 21 to move, for driving the servo motor 16 The servo driver 17 and the zero travel switch 18 used to mark the zero position of the powder spreading mechanism 21 movement, the servo driver 17 is connected to the output end of the powder spreading controller 6, and the servo motor 16 is connected to the servo driver 17 , the zero travel switch 18 is installed on the powder spreading platform 14 and connected to the input end of the powder spreading controller 6; Tube 2, falling powder tube 3 and photoelectric sensor 4, a light-transmitting tube 5 is connected between the upper powder-falling tube 2 and the falling powder tube 3, and the transmitting end and receiving end of the photoelectric sensor 4 are respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com