Wide beam multi-arm slot helical antenna

A technology of helical antenna and wide beam, applied in the field of wide-beam multi-arm slot helical antenna, can solve the problems of complex feeding structure of four-arm helical antenna, enhance the ability of coupling to metal slots, overcome the limitation of the number of arms, improve the The effect of antenna gain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

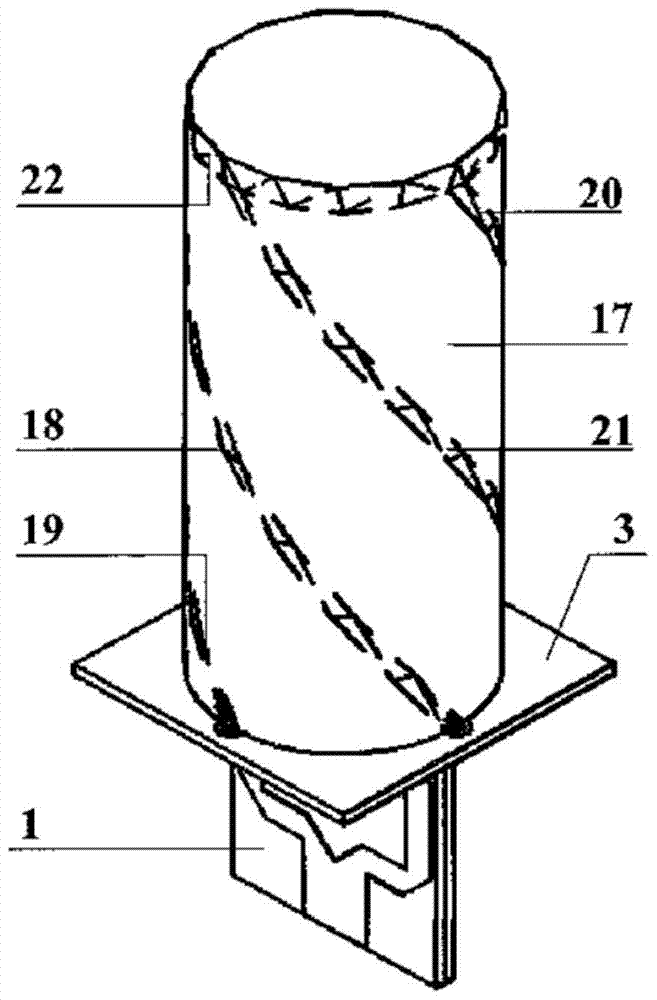

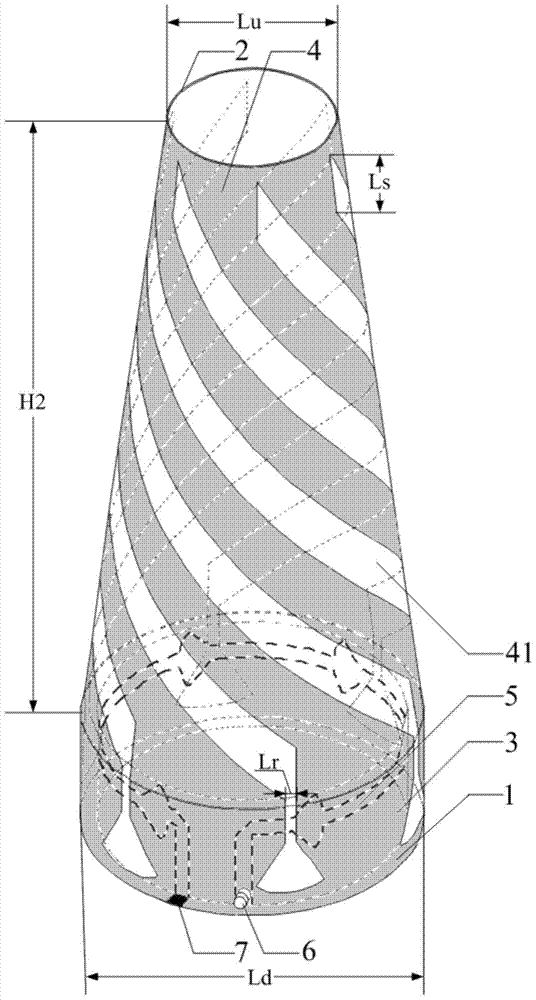

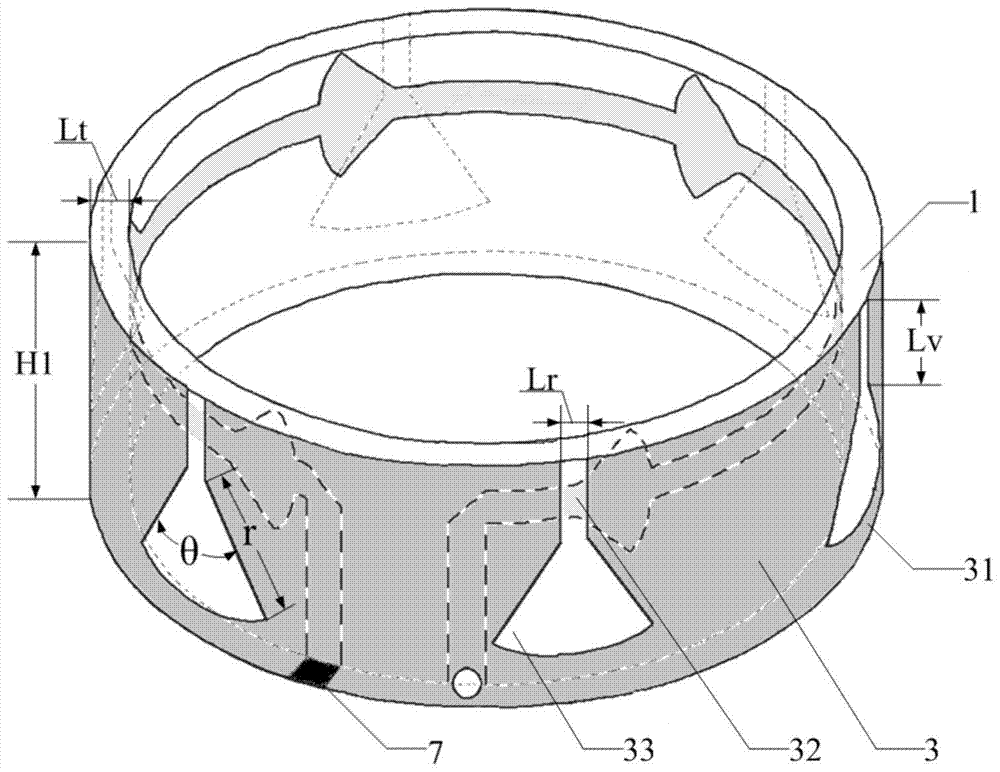

[0026] refer to figure 2 , the inner surface of the ring-shaped cylindrical dielectric substrate 1 is printed with a series fed microstrip line 5, and the outer surface of the ring-shaped cylindrical dielectric substrate 1 is printed with a ring-shaped cylindrical metal patch 3; 6 fan-shaped pieces are evenly distributed on the serial fed microstrip line 5 51; 6 uniformly distributed coupling adjustment slits 31 are etched on the annular columnar metal patch 3, the coupling adjustment slits 31 are composed of rectangular slits 32 and fan-shaped slits 33, and the radius and angle of each fan-shaped slit 33 are adjusted to ensure the The amplitude of the coupling feed is the same; the lower edge of the series-fed microstrip line 5 is on the same level as the lower edge of the rectangular slit 32, and the center of the fan-shaped piece 51 corresponds to the position of the rectangular slit 32, and its head end is connected to the inner core of the coaxial interface. The end is c...

Embodiment 2

[0029] The structure of embodiment 2 is identical with the structure of embodiment 1, and following parameter has been adjusted:

[0030] The outer diameter of the upper end of the annular tapered dielectric substrate 2 is Lu=0, and the number of radial spiral slots 41 , coupling adjustment slots 31 and sector pieces 51 is N=4.

Embodiment 3

[0031] The structure of embodiment 3 is identical with the structure of embodiment 1, and following parameter has been adjusted:

[0032] The outer diameter of the upper end of the annular tapered dielectric substrate 2 is Lu=40 mm, and the number of radial spiral slots 41 , coupling adjustment slots 31 and sector pieces 51 is N=8.

[0033] Effect of the present invention can be further explained in conjunction with simulation result:

[0034] 1. Simulation content

[0035] 1.1 Utilize commercial emulation software HFSS_15.0 to the S of above-mentioned embodiment 1 11 The parameters are simulated and calculated, and the results are as follows Figure 5 shown.

[0036] 1.2 Utilize the commercial simulation software HFSS_15.0 to simulate the axial ratio of the above-mentioned embodiment 1, the results are as follows Figure 6 shown.

[0037] 1.3 Utilize the commercial simulation software HFSS_15.0 to simulate and calculate the far-field radiation pattern of the above-mentio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com