Single-power and dual-drive reciprocating brush device

A dual-drive, reciprocating technology, applied in the field of processing machinery, can solve the problems of easy falling of workpieces, low work efficiency, flying, etc., and achieve the effects of low processing cost, simple structure and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

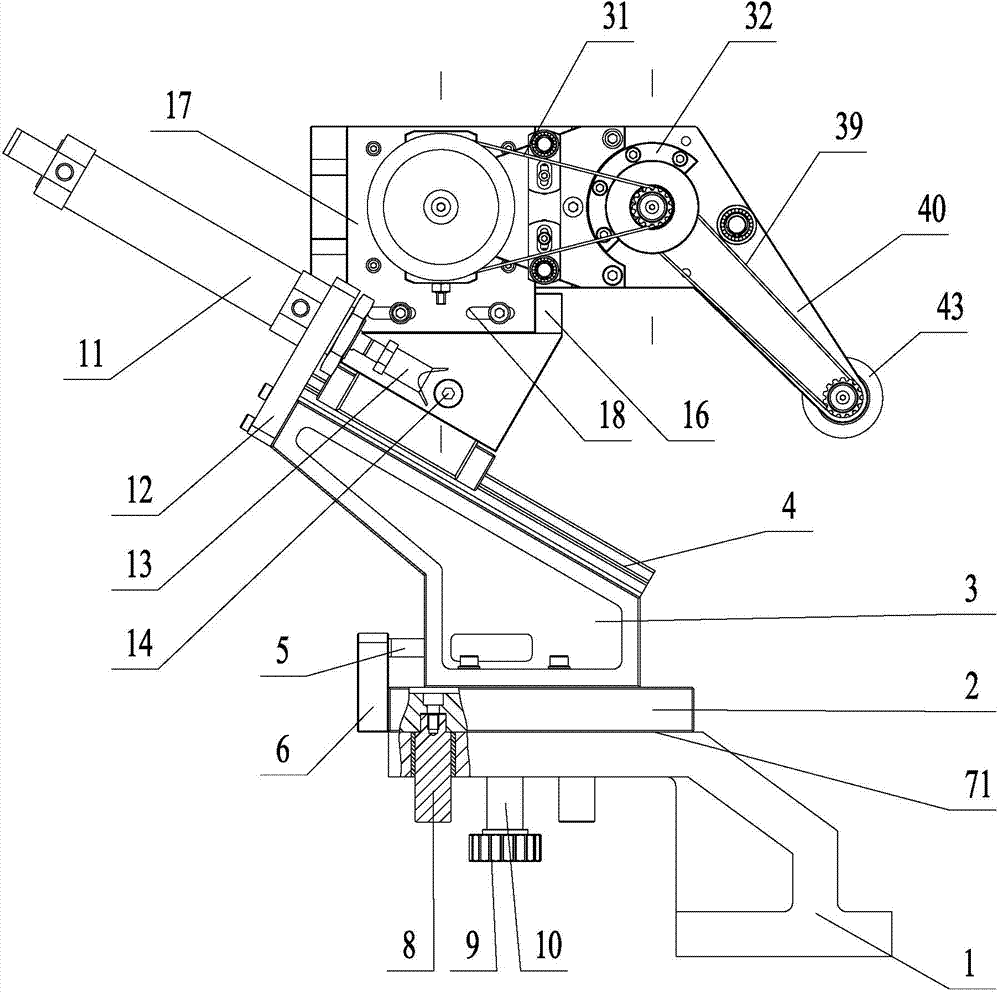

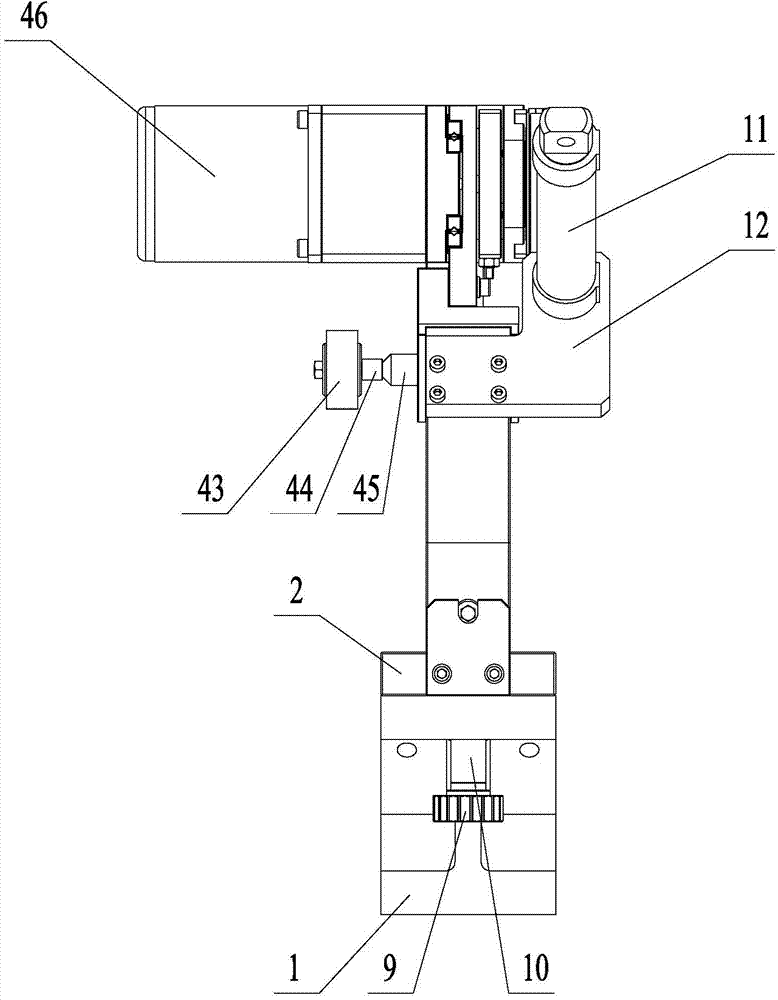

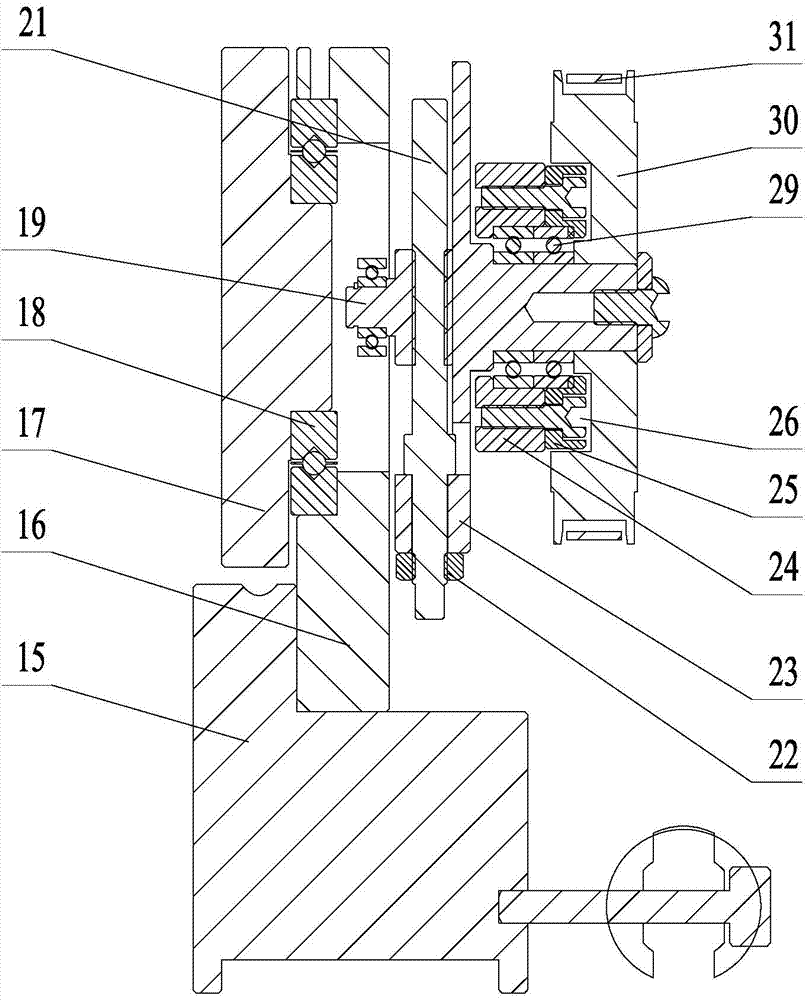

[0030] Refer to attached picture.

[0031] The present invention includes a brush 43, a brush driving mechanism and a position adjusting mechanism. The brush driving mechanism provides working power for the brush 43, and the position adjusting mechanism adjusts the position and stroke of the brush by driving the brush driving mechanism to move.

[0032] The brush driving mechanism comprises a motor 46, a synchronous driving mechanism and an adjustable eccentric cam mechanism, the motor 46 drives the synchronous driving mechanism, the synchronous driving mechanism drives the hairbrush 43, and the adjustable eccentric cam mechanism is linked with the synchronous driving mechanism, that is to say, the motor 46 It can drive the synchronous drive mechanism and the adjustable eccentric cam mechanism at the same time, but the speed of the adjustable eccentric cam mechanism is lower than that of the synchronous drive mechanism, so that when the motor drives the synchronous drive mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com