Lamination forming process method for fiber-metal mixed composite material

A technology of fiber composite materials and composite materials, which is applied in the field of lamination molding process of fiber-metal hybrid composite parts, can solve the problems that cannot completely overcome the forming problems of variable curvature structural parts, the difficulty of laminate laying process, and metal folds in variable curvature areas and other problems, to achieve the effect of good operability, good shape and size matching, and fast forming of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

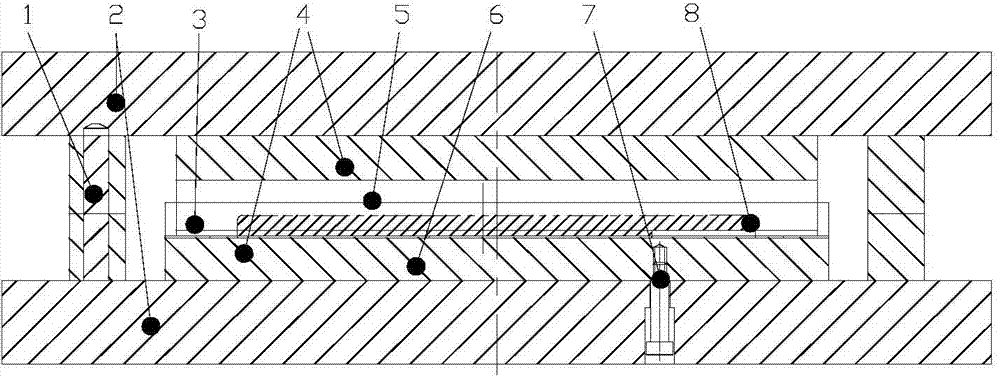

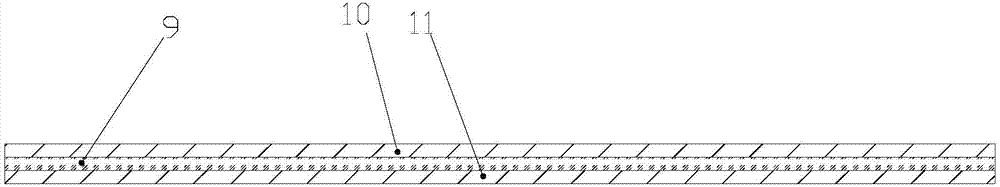

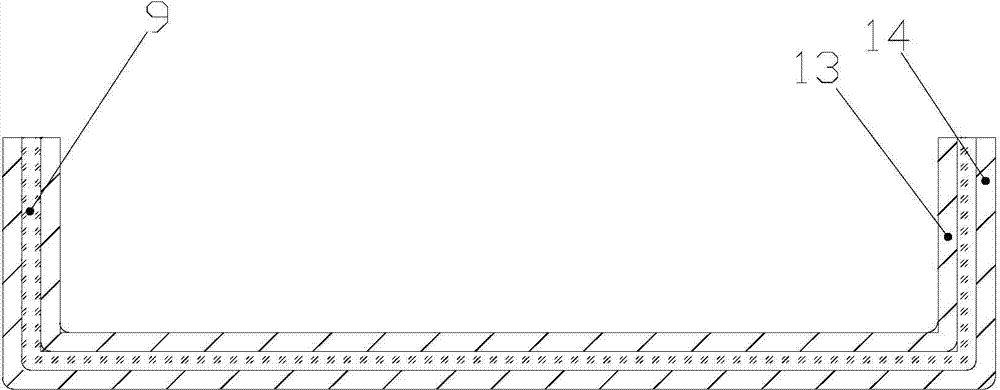

[0034] The channel-shaped glass fiber-aluminum alloy hybrid structural part is a typical one in the present invention, and the method of the present invention can realize the one-time punching of the channel-shaped aluminum alloy preform containing the transition R zone, and the channel-shaped glass fiber-aluminum alloy preform. For the forming of alloy laminates, the ratio of the metal layer to the fiber composite layer of the part is 2:1. figure 1 The schematic diagram of the stamping die used in the stack stamping of the present invention is disclosed, figure 2 The laminated aluminum alloy plate prepared before punching in the present invention is disclosed, image 3 A stamped laminated channel aluminum alloy article of the present invention is disclosed.

[0035] The molds involved ( figure 1 shown) is composed of the following parts: guide post 1, bottom die base 2, concave die 3, concave and convex die base 4, punch 5, top material plate 6, unloading screw 7.

[0036] ...

Embodiment 2

[0039] Embodiment 1 illustrates the molding method of one of the structures in the groove-shaped fiber-metal hybrid material part. The lamination stamping method can also be used to form groove-shaped parts with other layered structures. This embodiment describes the metal layer of the part and the fiber composite material. The ratio of the number of material layers is: 3:2 in the structure form using the process of lamination stamping method. The metal layer used in the grooved fiber-metal hybrid composite parts of this structure is TC4 titanium alloy, the thickness is 0.25mm, the cutting size is 70mm larger than the unfolded shape of the part, and the four corners of the material are cut into circles. Then, the interlayer aluminum alloy of the same size as the titanium alloy sheet is cut, and the interlayer aluminum alloy sheet is made of 2024-T3 aluminum alloy with a thickness of 0.8 mm. Lay the bottom layer titanium alloy sheet, the interlayer aluminum alloy sheet, the mid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com