Automobile axle case piece hydraulic-bugling two-stage pressurization system

A two-stage pressurization and hydraulic bulging technology, which is applied in the field of pipe fittings hydraulic bulging pressurization system to achieve the effects of good forming quality, low energy consumption and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

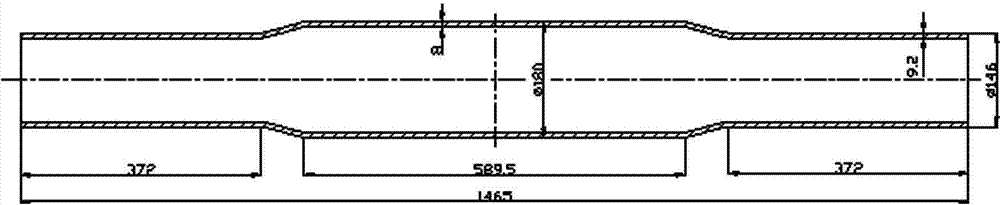

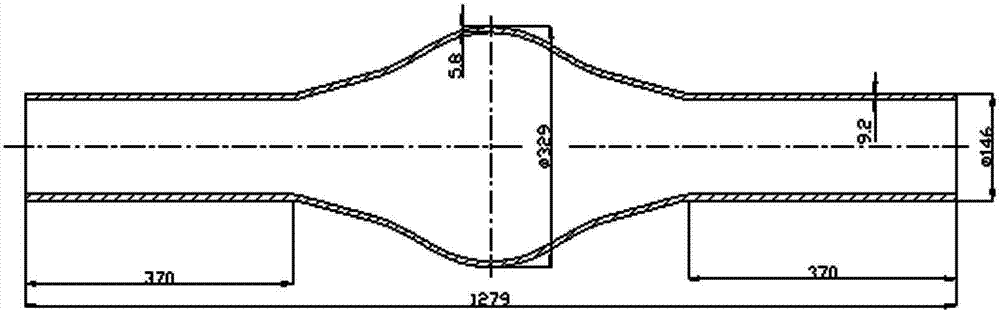

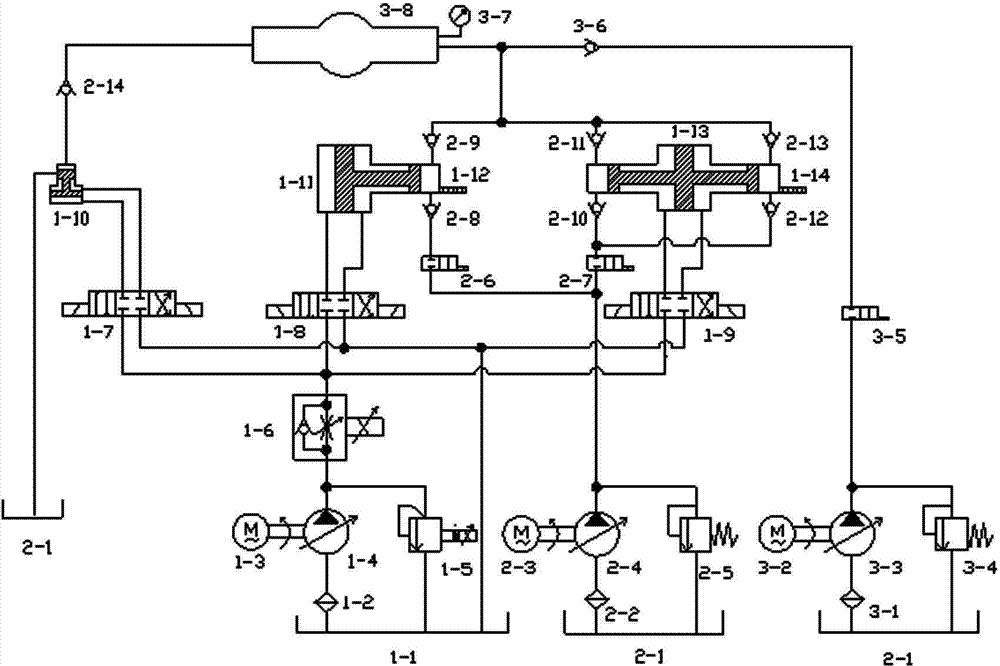

[0021] figure 1 It is the tube blank (3-8) before the hydraulic bulging of the axle housing of a 5T load-carrying automobile. 14) are connected; the right end of the tube blank (3-8) passes through the pipeline and check valve II (2-9), check valve IV (2-11) check valve VI (2-13) check valve VIII ( 3-6) are connected, and the right end of the tube blank (3-8) is equipped with a pressure sensor (3-7). The hydraulic bulging double-stage supercharging system of automobile axle housings is composed of four parts: image 3 ).

[0022] The low-pressure liquid filling system quickly replenishes the emulsion into the tube blank by the water pump II (3-3) before hydraulic bulging, and the inlet port of the water pump II (3-3) passes through the water suction filter II (3-1) and the water tank ( 2-1) is connected, the outlet port is connected with the end of the tube blank (3-8) through the on-off valve III (3-5) and the one-way valve VIII (3-6), and the bypass of the water pump II (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com