Oligomer surfactant clean fracturing fluid and preparation method thereof

A technology of surfactant and clean fracturing fluid, which is applied in the field of clean fracturing, oligomeric surfactant cleaning fracturing fluid and its preparation, and the synthesis process of oligomeric polyalkylene polyquaternary ammonium salt cationic surfactant, It can solve the problems of difficult control, high cost, and long synthesis time, and achieve the effects of short synthesis cycle, good shear resistance and temperature resistance, and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

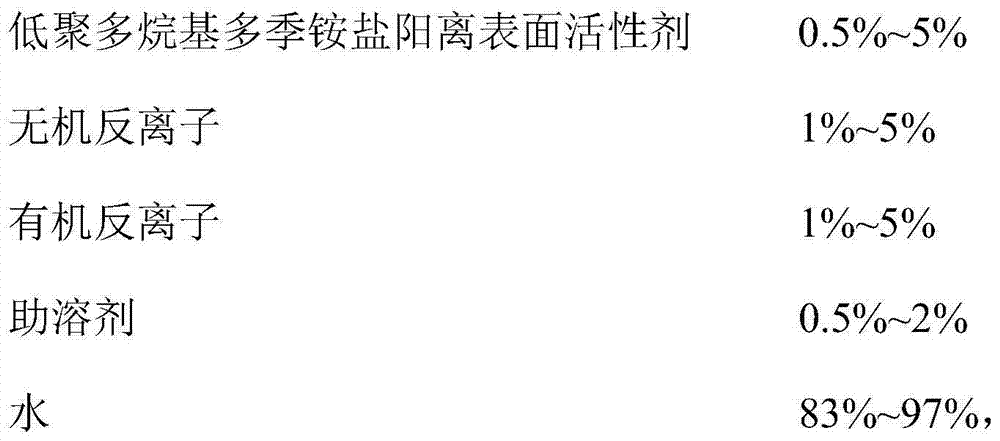

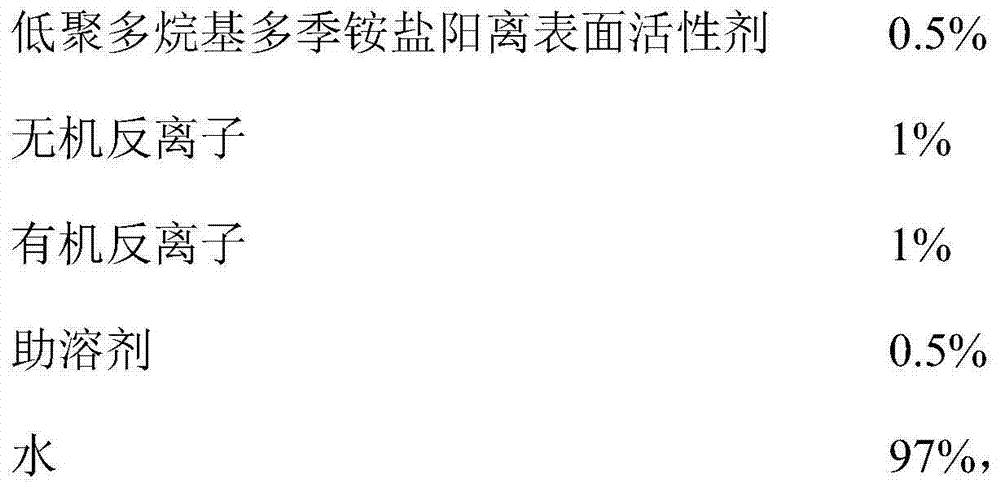

[0024] An oligomeric surfactant cleaning fracturing fluid, which is composed of the following components in mass percentage:

[0025]

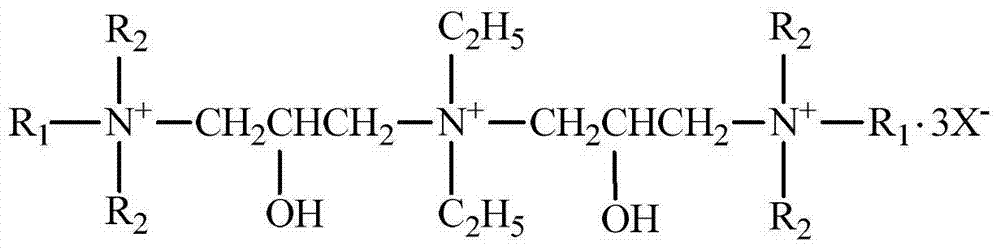

[0026] Among them, the molecular formula of oligomeric polyalkyl polyquaternary ammonium salt cationic surfactant is as follows:

[0027]

[0028] Where: R 1 Is a straight-chain saturated long-chain alkyl group containing 12 carbon atoms; R 2 Is methyl; X - For Cl - .

[0029] The preparation method of this embodiment includes the following steps:

[0030] Step 1. Weigh 15g of diethylamine into the reaction vessel, slowly add 17mL 6mol·L dropwise -1 Hydrochloric acid and 37g of epichlorohydrin, then add 50g of water, increase the temperature to 80°C and stir the reaction for 1.5h to obtain Intermediate A.

[0031] Step 2. Take 40g of Intermediate A and add it to the reactor, add dilute hydrochloric acid to adjust the pH to 7.0, then add 21g of dodecyldimethyl tertiary amine, then add 79g of water, and react for 2h under reflux;

[0032] Step 3. The crude...

Embodiment 2

[0041] An oligomeric surfactant cleaning fracturing fluid, which is composed of the following components in mass percentage:

[0042]

[0043] Among them, the molecular formula of oligomeric polyalkyl polyquaternary ammonium salt cationic surfactant is as follows:

[0044]

[0045] Where: R 1 Is a straight-chain saturated long-chain alkyl group containing 14 carbon atoms; R 2 Is methyl; X - For Cl - .

[0046] The preparation method of this embodiment includes the following steps:

[0047] Step 1. Weigh 15g of diethylamine into the reaction vessel and slowly add 17m 6mol·L dropwise -1 Hydrochloric acid and 37g of epichlorohydrin, then add 50g of water, increase the temperature to 80°C and stir the reaction for 1.5h to obtain Intermediate A.

[0048] Step 2: Take 40 g of Intermediate A and add it to the reactor, add hydrochloric acid to adjust the pH to 7.0, then add 22 g of tetradecyl dimethyl tertiary amine, then add 78 g of water, and react for 2 hours under reflux.

[0049] Step 3: Pu...

Embodiment 3

[0059] An oligomeric surfactant cleaning fracturing fluid, which is composed of the following components in mass percentage:

[0060]

[0061] Among them, the molecular formula of oligomeric polyalkyl polyquaternary ammonium salt cationic surfactant is as follows:

[0062]

[0063] Where: R 1 Is a straight-chain saturated long-chain alkyl group containing 16 carbon atoms; R 2 Is methyl; X - For Cl - .

[0064] The preparation method of this embodiment includes the following steps:

[0065] Step 1. Weigh 15g of diethylamine into the reaction vessel and slowly add 20m 5mol·L dropwise -1 Hydrochloric acid and 37g of epichlorohydrin, then add 50g of water, increase the temperature to 80°C and stir the reaction for 1.5h to obtain Intermediate A.

[0066] Step 2: Take 40g of Intermediate A and add it to the reactor, add hydrochloric acid to adjust the pH to 7.0, then add 23g of cetyldimethyl tertiary amine, then add 78g of water, and react for 2h under reflux.

[0067] Step 3: Purify the prepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com