Method for Gas Carbonitriding

A nitrocarburizing and gas phase technology, applied in metal material coating process, coating, solid diffusion coating and other directions, can solve the problem of dirt and other problems, and achieve the effect of reducing the stress peak and improving the running-in performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

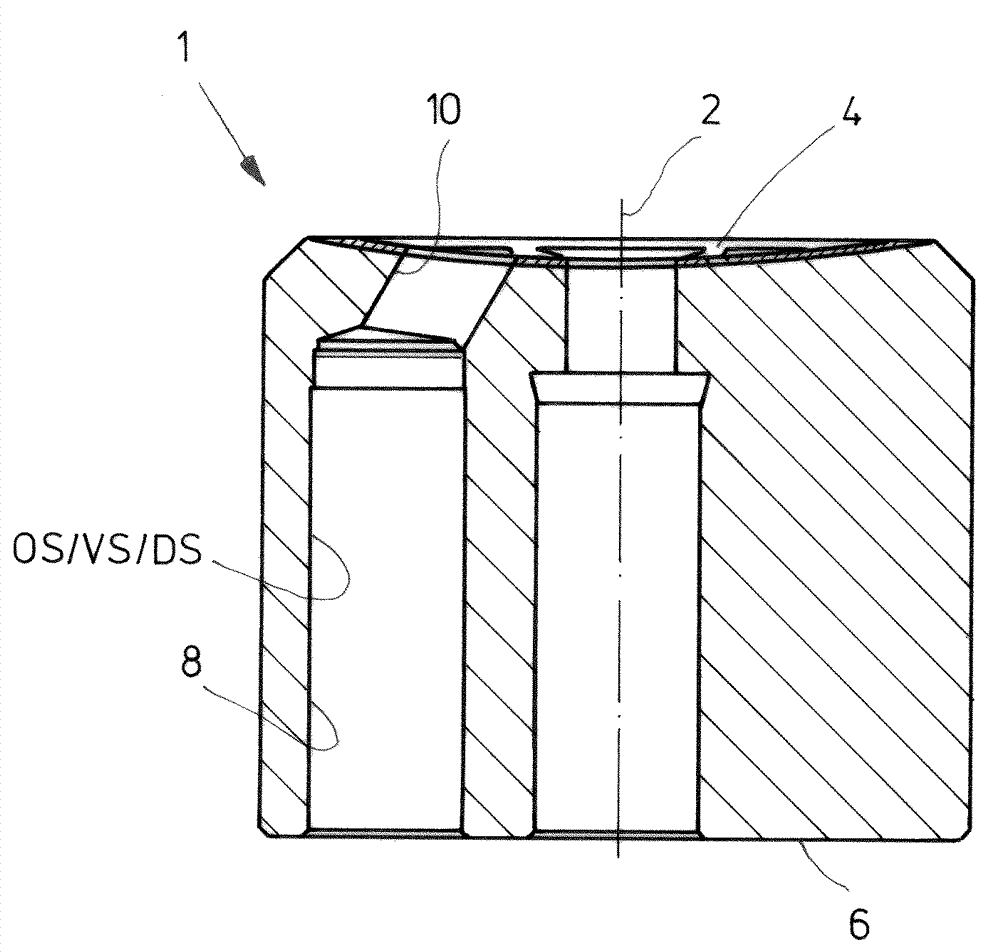

[0022] figure 1 A drum 1 of an embodiment of an axial piston machine according to the invention is shown in a cross-sectional illustration with an inclined axis. The drum has, for example, a cylindrical shape and rotates about its own longitudinal axis 2 during operation of the axial piston machine. The roller 1 is spherically shaped at the end face 4 and is pressed against the distribution plate with this end face 4 . The other end face 6 faces the flange of the drive shaft, relative to which the drum 1 is positioned in the case of a metering machine and can be positioned in different ways in the case of a variable machine. The angle is positioned relative to the flange.

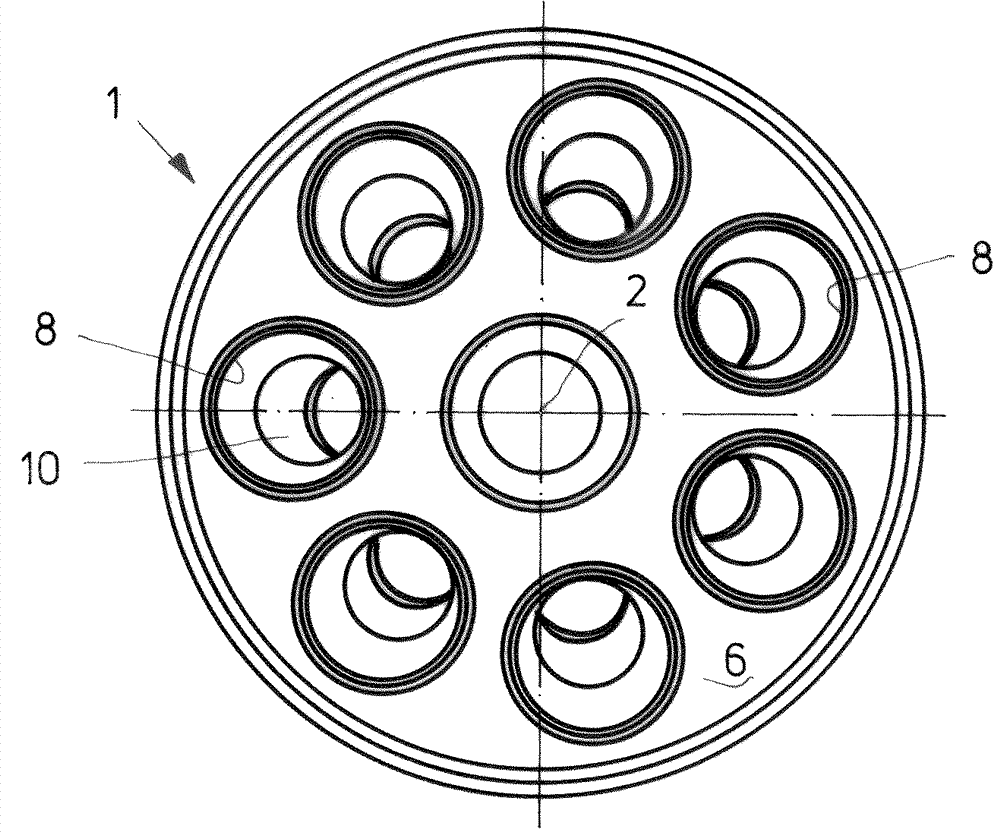

[0023] figure 2 A view of the end face 6 of the drum 1 is shown, facing the flange or the shaft. On the circumference of the shaft, a plurality of cylinder bores 8 are hollowed out in an evenly distributed manner, said cylinder bores extending over most of the length of the drum 1 .

[0024] refer to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com