Construction waste recycled aggregate composite carrier pile and preparation method thereof

A construction waste and composite carrier technology, which is applied in construction, sheet pile walls, solid waste management, etc., can solve problems such as land occupation, land secondary pollution cost, and environmental pollution, so as to reduce engineering volume, realize economic benefits, and improve construction efficiency. The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

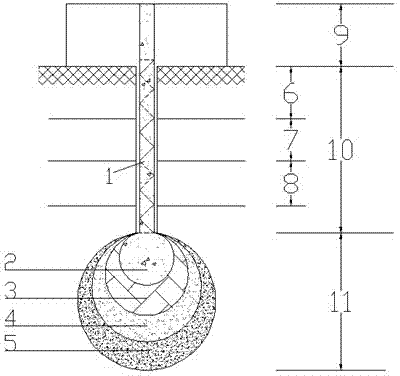

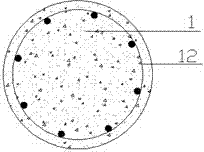

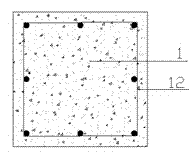

[0046]A construction waste recycled aggregate composite carrier pile, mainly composed of a tamping body (11), a pile body (10), and a cushion layer (9), as shown in figure 1 shown;

[0047] 1. The tamping body (11) is mainly prepared from the following raw materials:

[0048] Sorted construction waste (3), cement, fly ash, construction waste coarse aggregate, blast furnace slag, water, water reducing agent;

[0049] The sorted construction waste (3) is lumpy construction waste with a geometric size of 50-150 mm after screening;

[0050] Described cement is ordinary portland cement, grade is 42.5;

[0051] The fly ash is grade II fly ash;

[0052] The construction waste coarse aggregate is construction waste with a particle size of 5-40mm after crushing and screening;

[0053] The blast furnace slag is industrial undisturbed slag;

[0054] The water reducer is a naphthalene-based high-efficiency water reducer;

[0055] Mix cement, fly ash, construction waste coarse aggreg...

Embodiment 2

[0084] A method of construction waste recycled aggregate composite carrier pile, comprising the following steps:

[0085] A construction waste recycled aggregate composite carrier pile, mainly composed of a tamping body (11), a pile body (10), and a cushion layer (9);

[0086] 1. The tamping body (11) is mainly prepared from the following raw materials:

[0087] Sorted construction waste, cement, fly ash, construction waste coarse aggregate, blast furnace slag, water, water reducing agent;

[0088] The sorted construction waste (3) is blocky construction waste with geometric dimensions of 50 to 150 mm after screening;

[0089] Described cement is ordinary portland cement, grade is 42.5;

[0090] The fly ash is grade II fly ash;

[0091] The construction waste coarse aggregate is construction waste with a particle size of 5-40mm after crushing and screening;

[0092] The blast furnace slag is industrial undisturbed slag;

[0093] The water reducer is a naphthalene-based hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com