High-pressure flame water-cooling gasification supercharging turbine engine

A turbine engine and supercharger turbine technology, which is applied to gas turbine devices, machines/engines, mechanical equipment, etc., can solve the problems of high cost, expense, and inability to solve the heat deformation of fans, and achieve the effect of lowering the technical threshold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

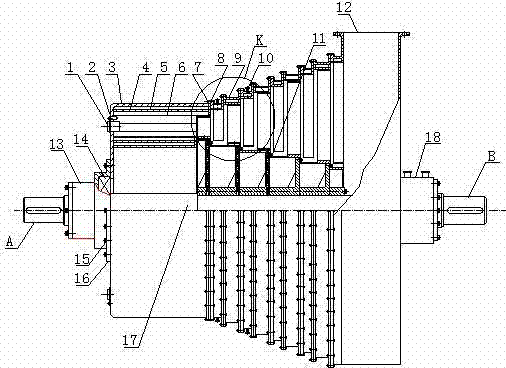

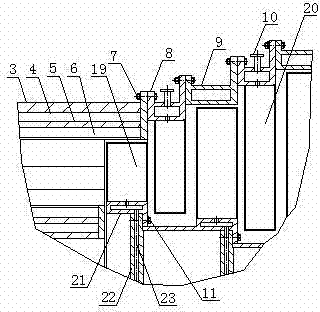

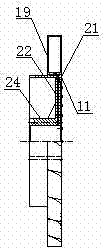

[0021] See attached figure 1 , 2, 3, 4, 5, 6, 7, 8, 9, 10, a kind of high-pressure flame water cooling gasification supercharged turbine engine disclosed by the present invention, its principle is: follow the first law of passive heating dynamics and the first law The second law, for the high-pressure flame injected by the turbine engine, the cooling water used to cool the moving and stationary blades of the turbine is sprayed from the top of the hollow blade or other injection methods are used to cool down and replace the non-combustible gas material in the fuel. The high expansion rate obtained after water vaporization increases the operating power of the engine, and the high-pressure flame water cooling gasification supercharged turbo engine is made accordingly; the high-pressure flame water cooling gasification supercharged turbo engine involved, its The technical features of the structure are: the high-pressure flame chamber fixed shell 3 is provided with a number of bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com