Car lamp

A technology of car lights and LED lights, which is applied in the field of lighting, can solve problems such as increasing product production costs, reducing product yield, and complicated processes, and achieves the effects of avoiding damage, improving service life, and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

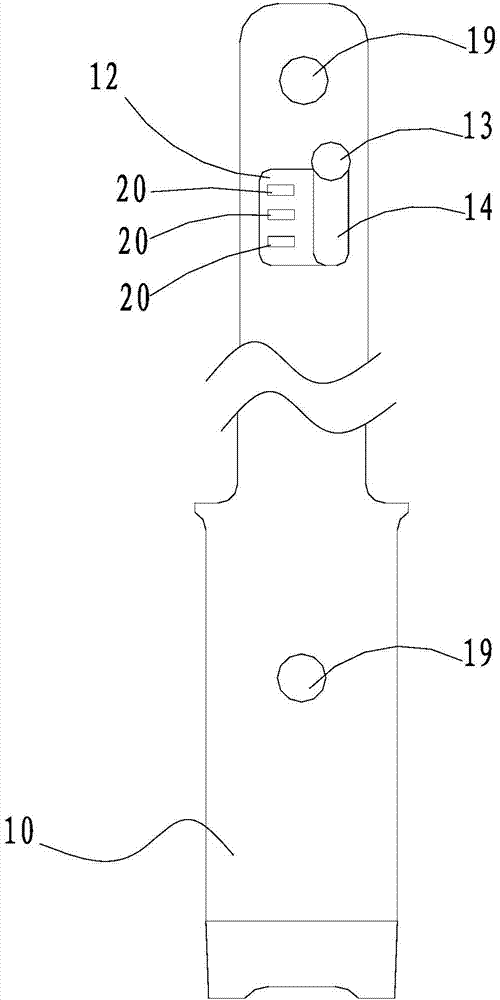

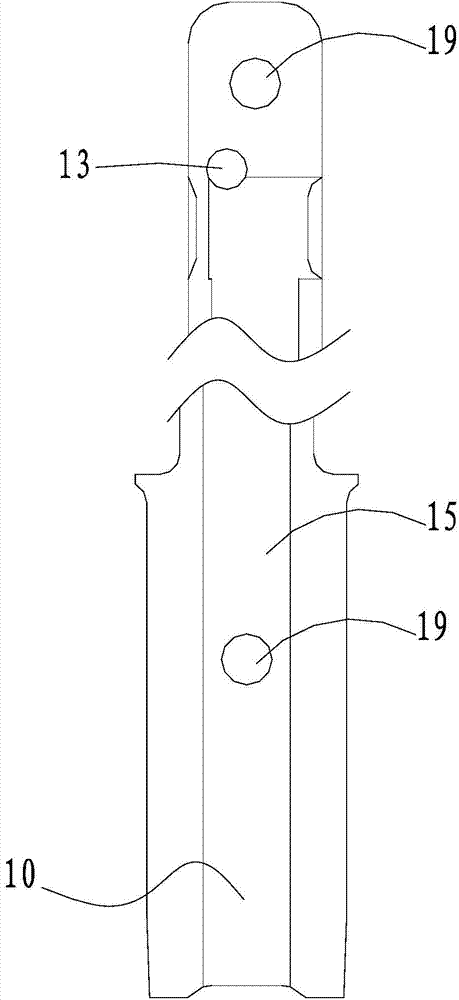

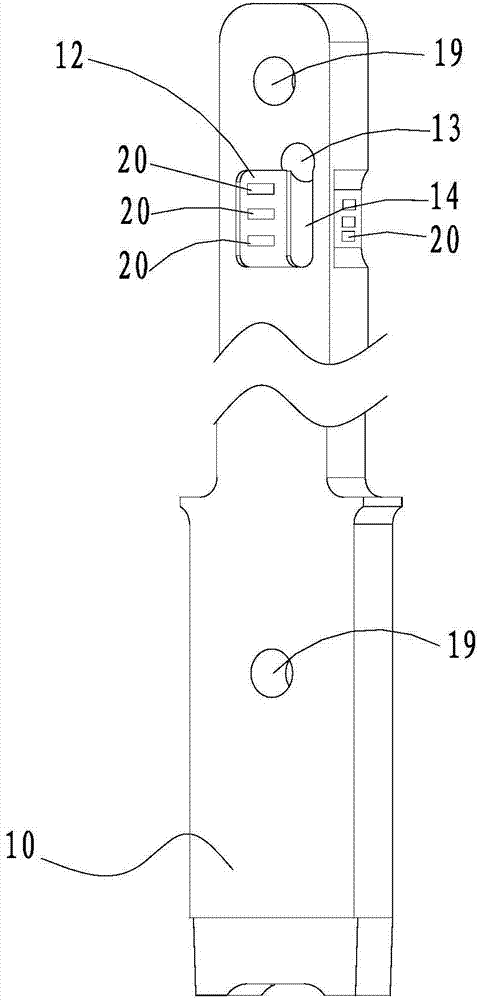

[0032] Embodiments of the present invention are described in detail below:

[0033] Such as Figure 1-4 , as shown in any one of 6-9, the vehicle lamp according to the present invention includes a column body 10 , a chip or an LED lamp 20 . The side wall of the column 10 has a light emitting area 12, the wafer or LED lamp 20 is disposed in the light emitting area 12, and a channel (not shown in the figure) is provided inside the column 10 . One end of the channel is connected to the bottom of the cylinder 10 , and the other end of the channel is connected to the light emitting area 12 .

[0034] According to the vehicle light of the present invention, a channel is provided inside the column body 10 , and a light-emitting area 12 is provided on the side wall of the column body 10 . The power leads can be routed from the channel inside the column 10 to the light-emitting area 12 on the side wall of the column 10 and electrically connected to the chip or LED lamp 20 to prevent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com