Method for evaluating composite insulator silicone rubber aging degree based on Fourier infrared spectroscopy

A composite insulator and infrared spectroscopy technology, which is applied in the field of electrical inspection, can solve the problems of hidden dangers of power system safety, unfavorable early judgment of aging, and insufficient sensitivity of aging change process, so as to achieve the effects of accurate measurement data, convenient measurement and small workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

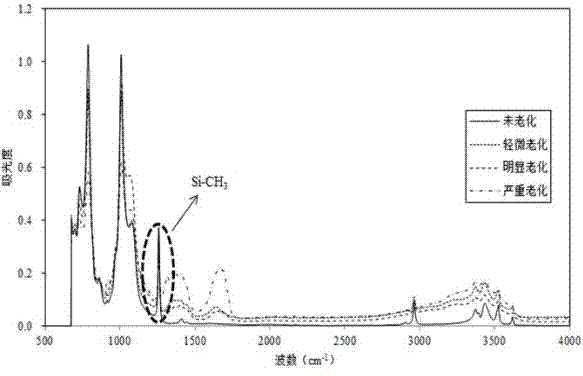

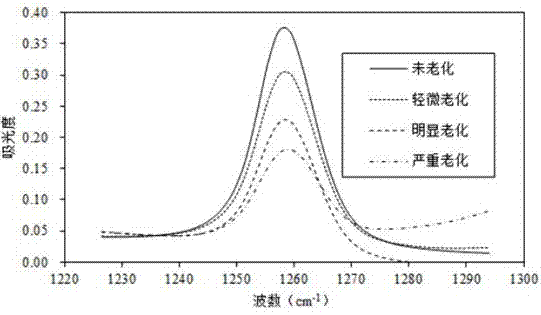

[0019] Attached below figure 1 The method for evaluating the aging degree of silicone rubber based on Fourier transform infrared spectroscopy is described in detail. The infrared spectrometer selected is the Thermo Fisher Nicolet Is10 FT-IR spectrometer produced by Thermo Fisher Corporation of the United States, which is a mid-infrared spectrometer with a scanning range of 400cm -1 ~4000cm -1 , the transmission mode is attenuated total reflection, the number of scans is 32 times, and the wavenumber in the spectrogram is 1286cm using OMNIC software -1 ~1236cm -1 Si-CH 3 Calculate the peak area and take the corrected peak area.

[0020] (1) Select test samples, and select a piece of shed and shed at the high-voltage end, low-voltage end and middle of the composite insulator respectively. The selected parts are preferably powdered, whitened, silver streaked or ablated;

[0021] (2) Cut the selected umbrella skirt and umbrella cover. The size of the cut sample should be 1cm×...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com