Quality control method and device

A technology of a control device and a quality control system, applied in the field of quality control methods and devices, can solve problems such as inability to monitor and analyze production links in real time, and inability to meet actual needs, so as to ensure timeliness and reliability, fast response, and reliability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

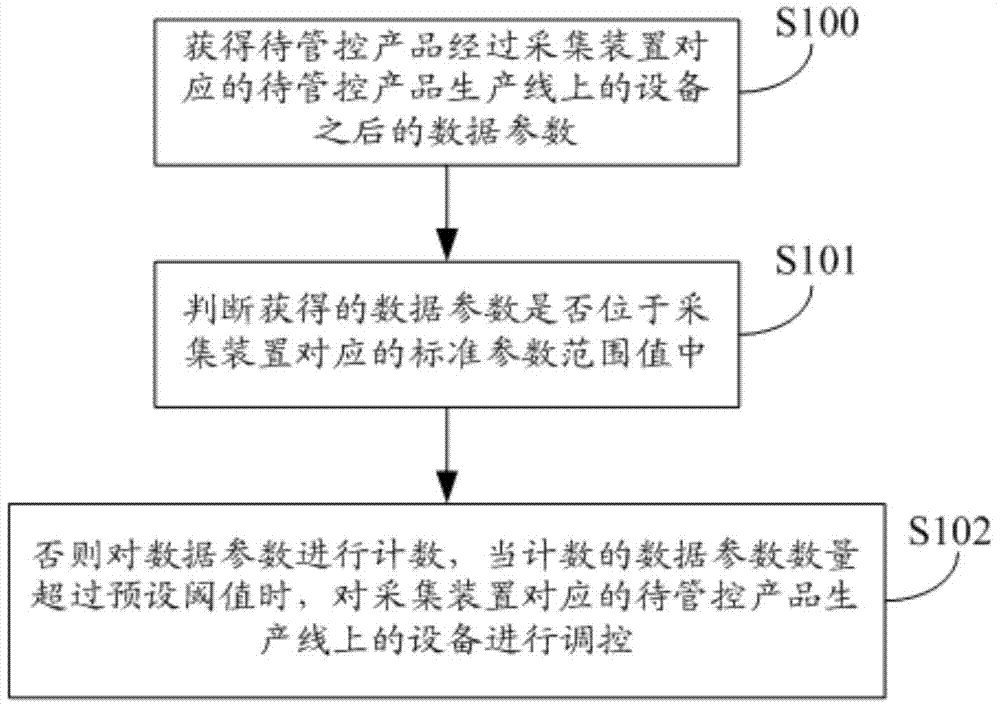

Embodiment 1

[0054] Statistical Process Control (SPC) is a commonly used product quality control method at present. SPC believes that when the process is only affected by random factors, the process is in a state of statistical control, referred to as the controlled state; when there are systematic factors in the process The process is in a statistically out-of-control state, referred to as the out-of-control state. Due to the statistical regularity of process fluctuations, when the process is under control, the process characteristics generally obey a stable random distribution; when the process is out of control, the process distribution will change. SPC uses the statistical regularity of process fluctuations to analyze and control the process. Therefore, it emphasizes that the process is operated under control and capability, so that products and services can stably meet customer requirements. The process of implementing SPC is generally divided into two steps: first, use SPC tools to ...

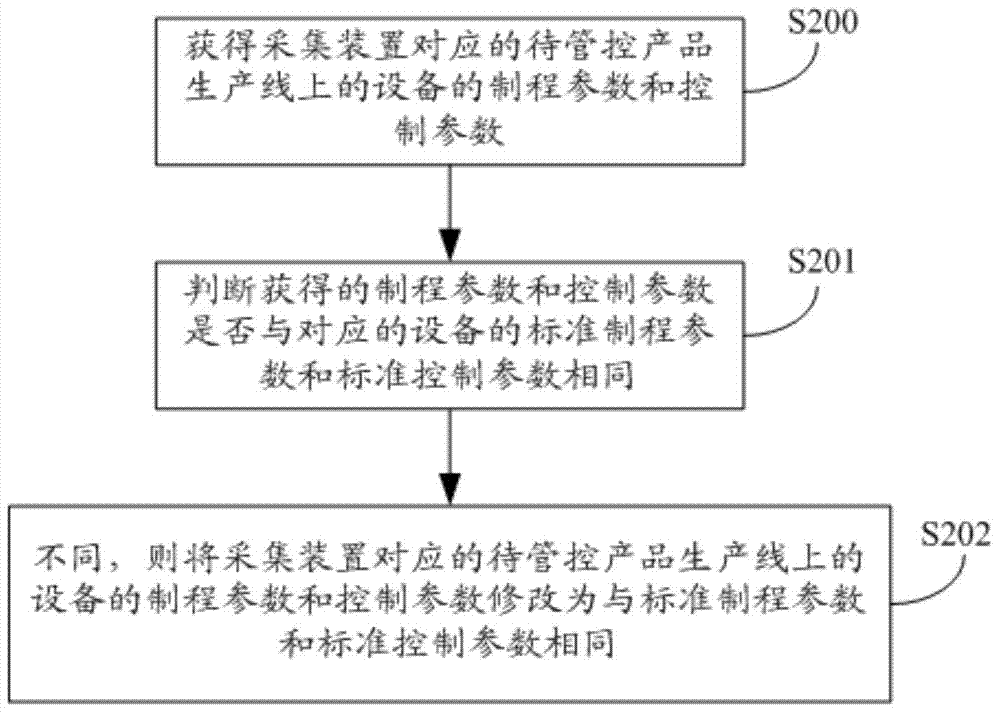

Embodiment 2

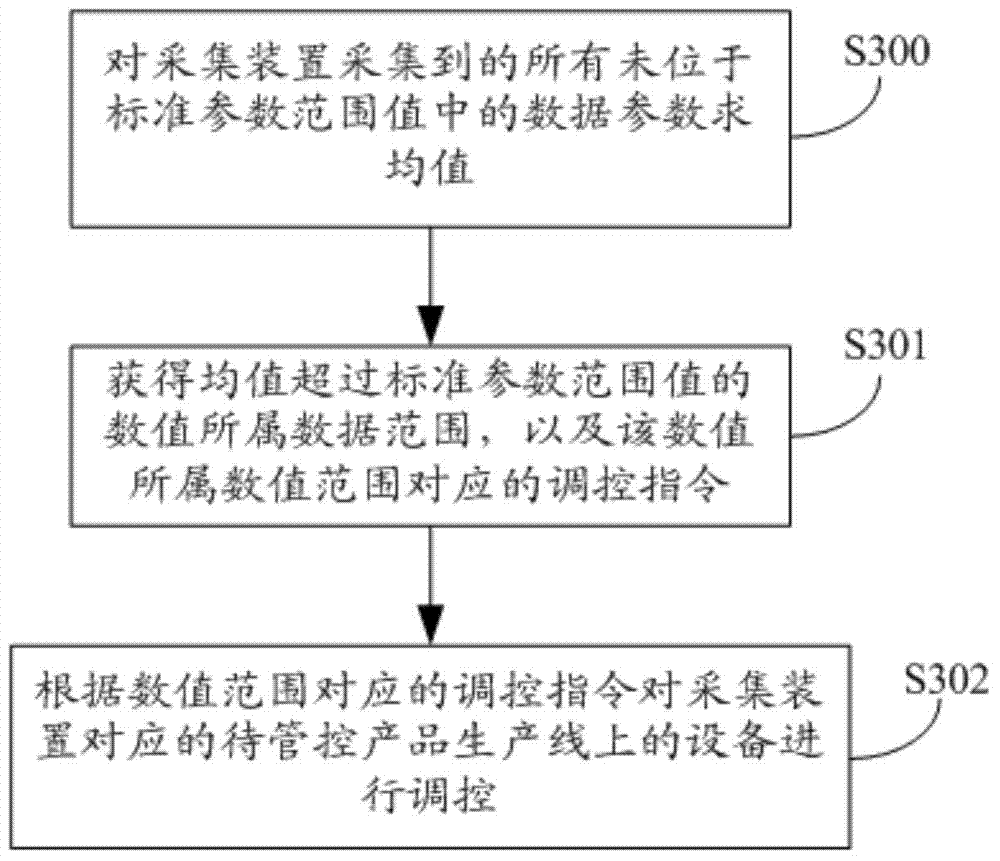

[0070] Such as Figure 5 As shown, the embodiment of the present invention provides a quality control device, which is applied to a quality control system. The quality control system includes a collection device and the quality control device. The quality control device is preset with a data correspondence relationship. The data correspondence includes the standard parameter range value corresponding to the collection device and the equipment on the production line of the product to be controlled corresponding to the collection device; The data parameters after the equipment on the production line of the product to be controlled, the quality control device includes: an obtaining unit 600, configured to obtain the product to be controlled collected by the collection device and corresponding to the product to be controlled by the collection device The data parameters after the equipment on the production line; the judging unit 601 is used to judge whether the data parameters obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com