Control method and driving system of three-phase double-salient-pole brushless direct current motor

A brush DC motor and drive system technology, applied in the direction of excitation or armature current control, can solve the problems of torque ripple reduction, soft mechanical characteristics, and motor power failure, so as to reduce the generation of negative torque, Improvement of output power and work efficiency, positive torque output increase effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The technical solutions of the present invention will be described in detail below with reference to the accompanying drawings.

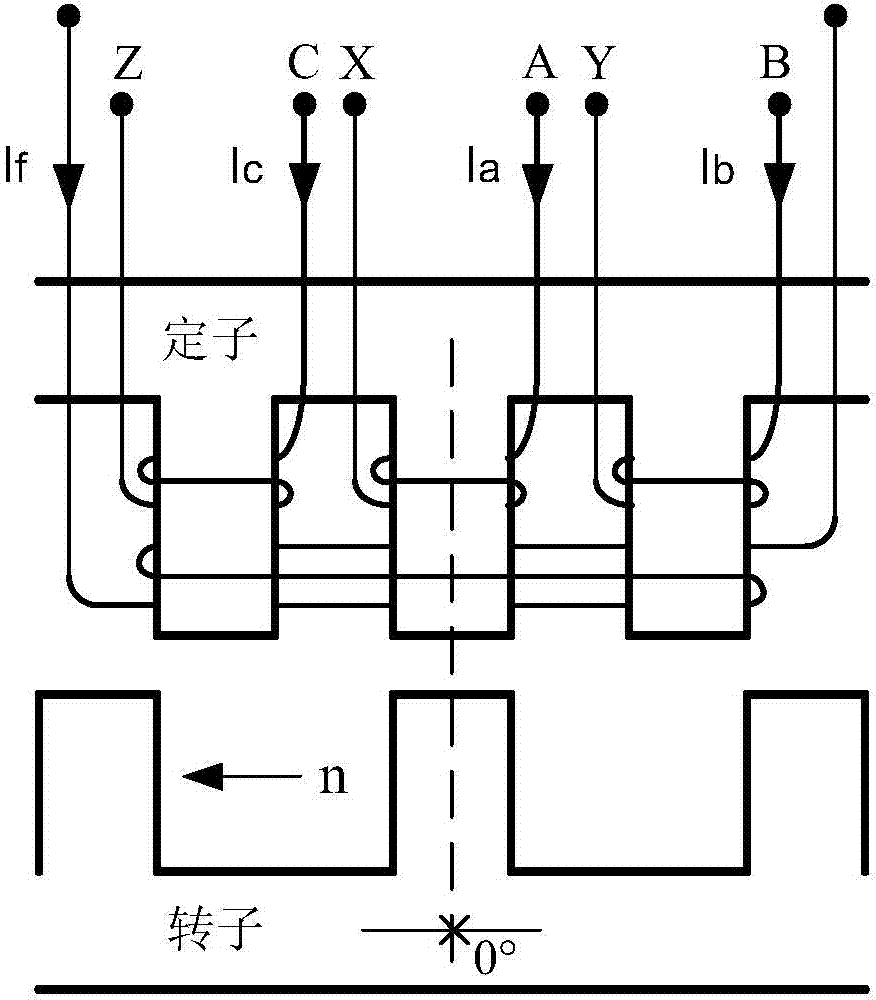

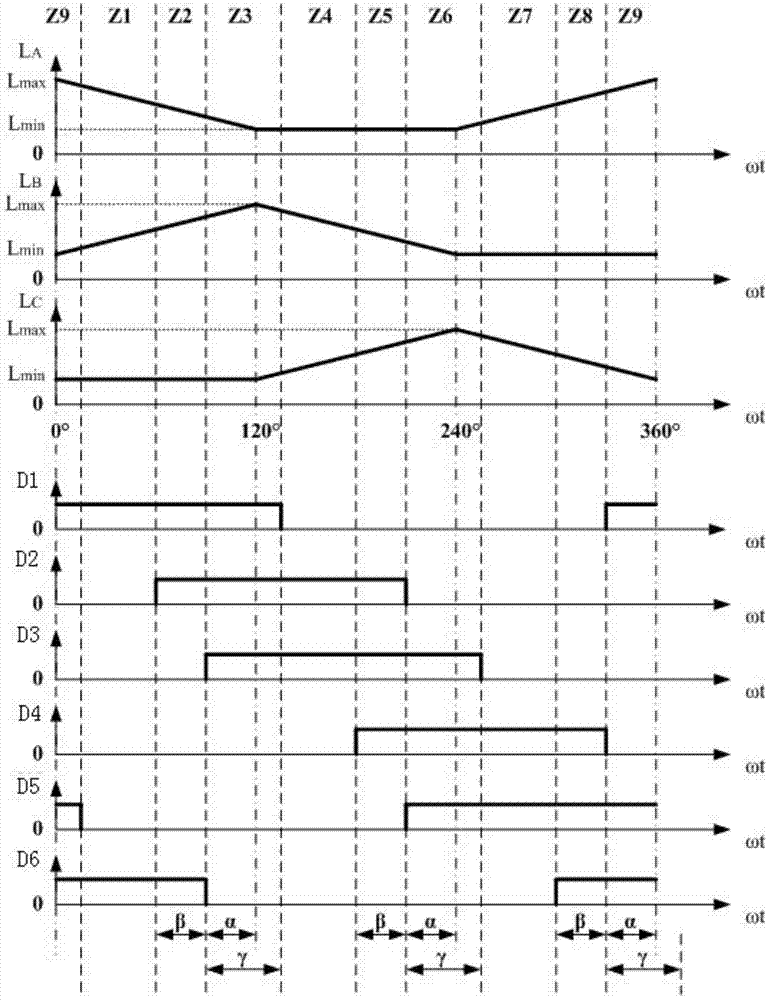

[0070] like figure 1 The expansion diagram of the stator and rotor of the three-phase electric excitation doubly salient motor is shown. The doubly salient motor is of electric excitation type. The excitation winding is placed on the stator, including three stator poles of A phase, B phase and C phase, and A phase is placed respectively. , B-phase, C-phase armature winding, the excitation current I in the figure f The direction is defined as the positive direction; in the figure, the phase A stator pole and the rotor pole are in the positive state, and the phase A inductance reaches the maximum value, and the electrical angle of this position is defined as 0°; the rotor rotation direction n in the figure is counterclockwise rotation, and the The direction of rotation is defined as the positive direction.

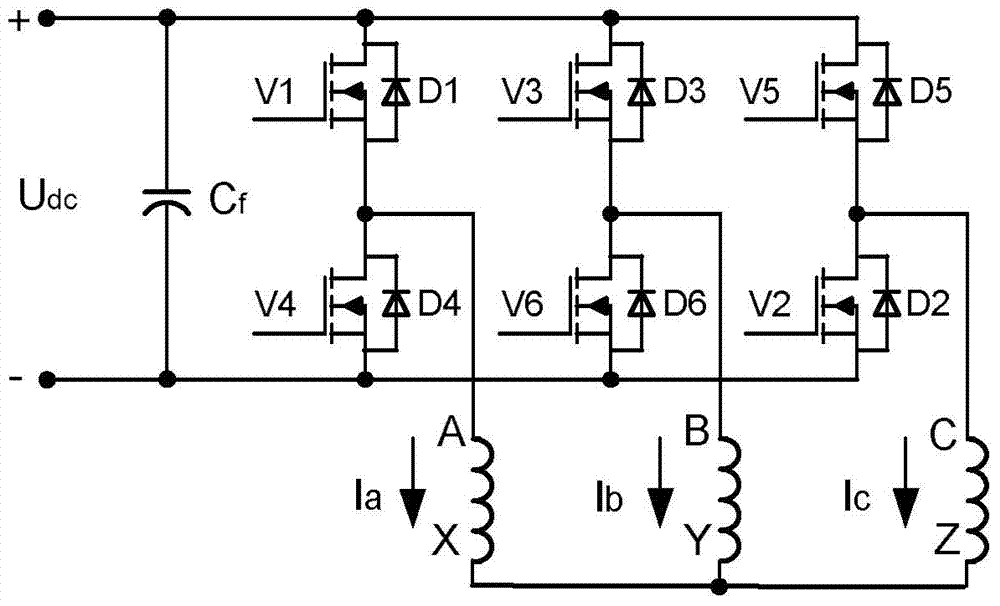

[0071] like figure 2 The schemat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com