Tuber crop seed cutter with lifting device

A cutting machine, crop technology, applied in the direction of seed and rhizome treatment, application, agriculture, etc., can solve the problems of low efficiency, long seed stacking time, increased production costs, etc., to avoid the work of handling and feeding, cutting The effect of saving time and labor and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

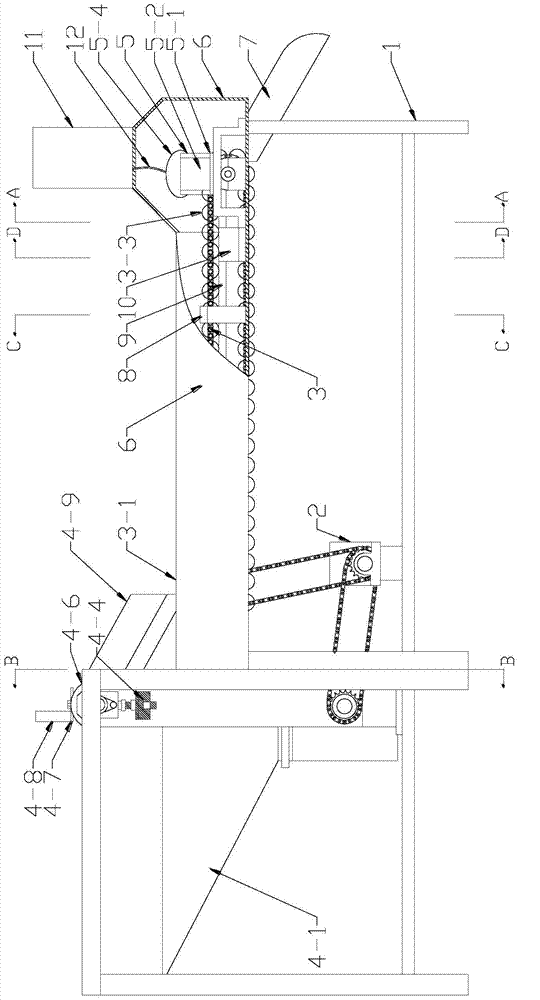

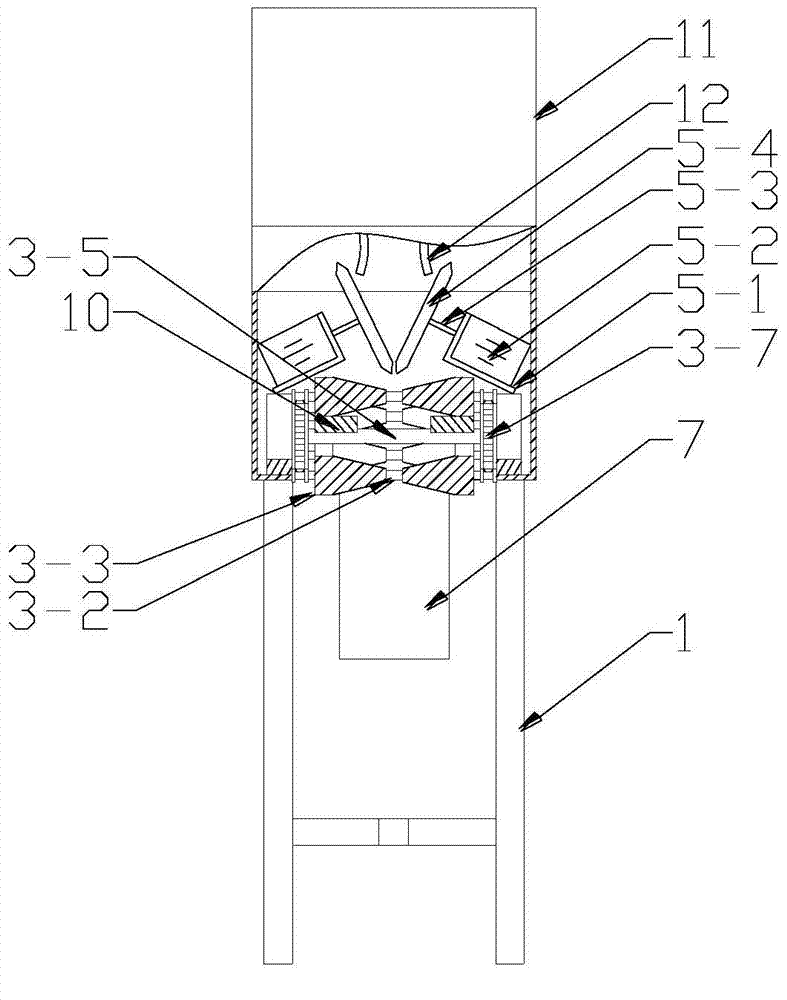

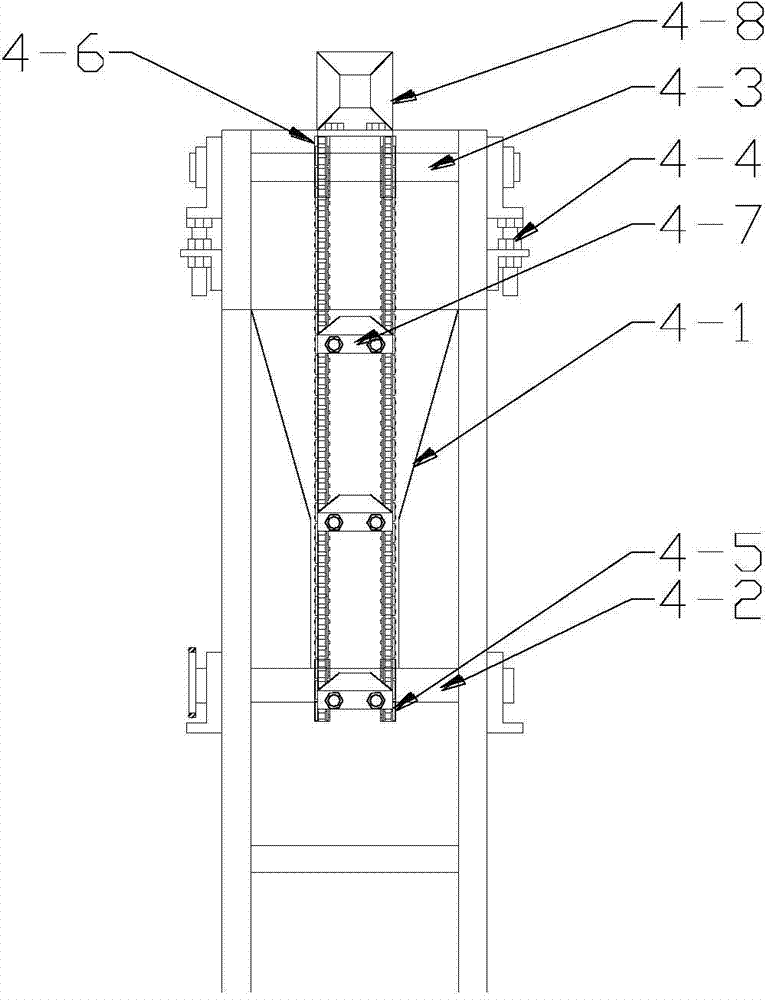

[0016] Such as Figure 1-5 As shown, the tuber crop seed cutting machine with a lifting device includes a frame 1, and the frame 1 plays a supporting and stable role; the bottom of the frame 1 is provided with a speed-regulating motor 2, and the speed-regulating motor 2 provides power; the frame 1 top is provided with conveying mechanism 3, and conveying mechanism 3 is mainly used for conveying the tuber crop with bud eye, and speed regulating motor 2 is connected with conveying mechanism 3 by chain transmission, and conveying mechanism 3 works under the drive of chain; The starting end of the conveying is provided with a feeding port 3-1, and the feeding port 4-9 of the lifting device 4 is placed above the feeding port 3-1. 1 enters the conveying mechanism 3; the conveying end of the conveying mechanism 3 is provided with a cutting mechanism 5, and the cutting mechanism 5 will move to the tuber crops with bud eyes at the conveying end of the conveying mechanism 3 to cut into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com