Combined Mecanum wheel hub

A combination and hub technology, applied in hubs, wheels, transportation and packaging, etc., can solve the problems that the processing accuracy of positioning pin holes cannot be guaranteed, affects the assembly accuracy, and requires high dimensional accuracy and position accuracy of positioning pin holes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Refer to attached figure 1 to attach Figure 5 .

[0066] The technical solution adopted by the present invention to solve its technical problems is:

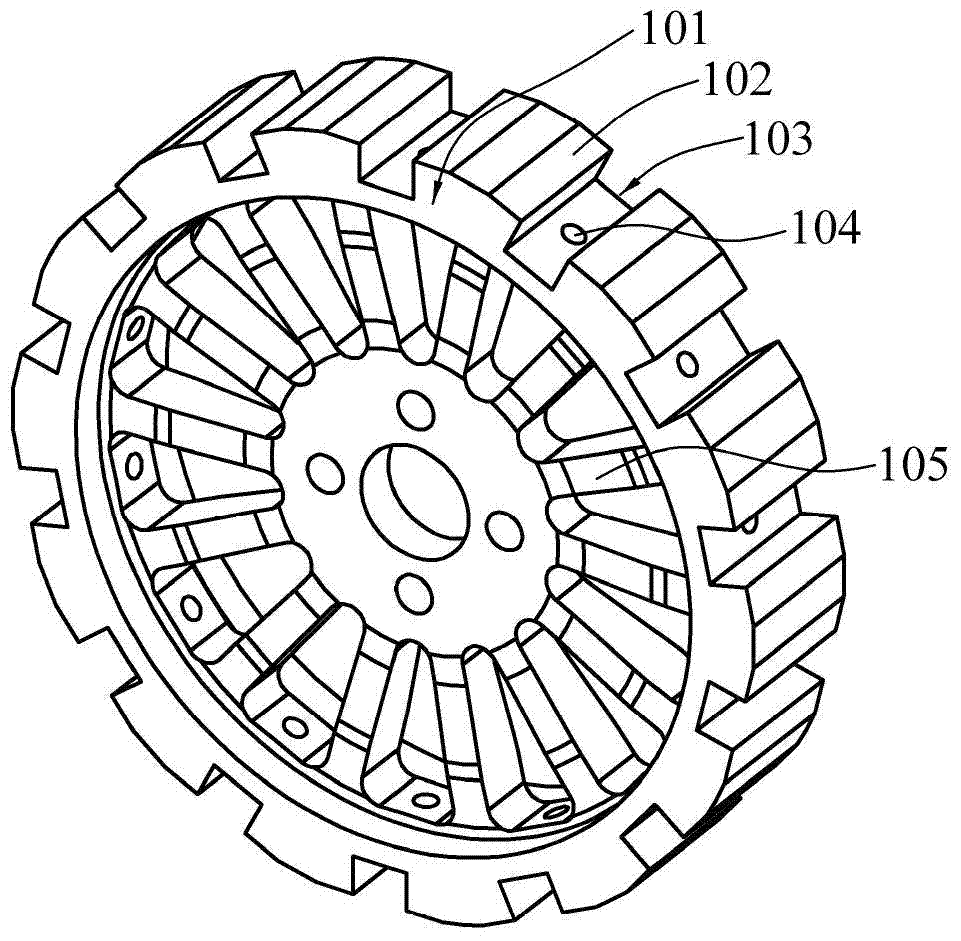

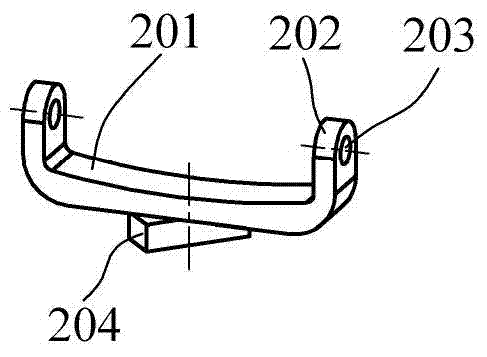

[0067] The first embodiment of the combined mecanum wheel hub is a two-side supported mecanum wheel hub, which includes a hub body 1 and a plurality of roller support frames, and the roller support frame adopts a roller support fork 2; figure 1 As shown, the rim 101 of the hub body 1 is provided with a plurality of connecting interfaces, and the connecting interfaces are distributed in a circular array with the axis of the hub body as the center line; the connecting interfaces include a side plane 102, a positioning groove 103 and a positioning The hole 104, the side plane 102 is set on the hub body 1 and parallel to the axis of the hub body 1, the positioning groove 103 is set in the center of the side plane 102 along the axial direction of the hub body 1, and the positioning hole 104 is set in the positioning groove ...

Embodiment 2

[0071] Refer to attached Image 6 To attach Figure 7 .

[0072] Embodiment 2 is also a two-side supported mecanum wheel hub. Embodiment 2 uses the same roller support fork as Embodiment 1. The difference from Embodiment 1 is that the overall size of the hub body in Embodiment 2 is smaller than that of Embodiment 2. The hub body of Example 1, but the size of the positioning groove and the positioning hole in the positioning groove of the hub body connection interface of the second embodiment is the same as that of the first embodiment. Like this, the connection mode of the roller support fork and the hub body of the second embodiment is the same, and the front view of assembling the second embodiment is as follows Image 6 shown. Through this combination, using the same roller support fork and hub bodies of different sizes and specifications, the Mecanum wheel hubs of different sizes and specifications are combined. Mecanum wheels of different sizes and specifications can ...

Embodiment 3

[0074] Refer to attached Figure 8 To attach Figure 12 .

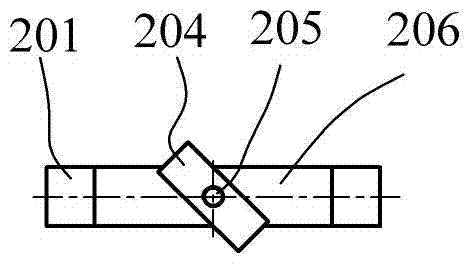

[0075] Embodiment 3 is also a two-sided supported Mecanum wheel hub, which is different from Embodiment 1 in that: the hub body 1 is a regular polygon, and the side of the regular polygon is used as the side plane 102 of the connection interface. A positioning groove 103 is provided in the center of the side plane 102, such as Figure 8 shown; and a positioning block 204 is provided on the bottom plane 206 of the roller support fork 2, and the bottom surface of the positioning block 204 is square, and the extending direction of the positioning block 204 forms an oblique angle with the axis of the roller shaft hole 203 is 45 degrees, such as Figure 9 , 10 As shown; when the roller support fork 2 is connected with the hub body 1, the positioning block 204 is embedded in the positioning groove 103 on the hub body 1, and the two parallel sides of the positioning block 204 are respectively used as the positioning posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com