An indirect cooling tower with triangular petal-like arrangement

A cooling triangle and cooling tower technology, applied in the field of indirect cooling towers, can solve the problems of increasing the diameter of the tower, affecting the ventilation volume, and small heat exchange area, so as to achieve uniform flow field and temperature field in the tower, large air density difference, The effect of reducing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention is described in detail below in conjunction with accompanying drawing:

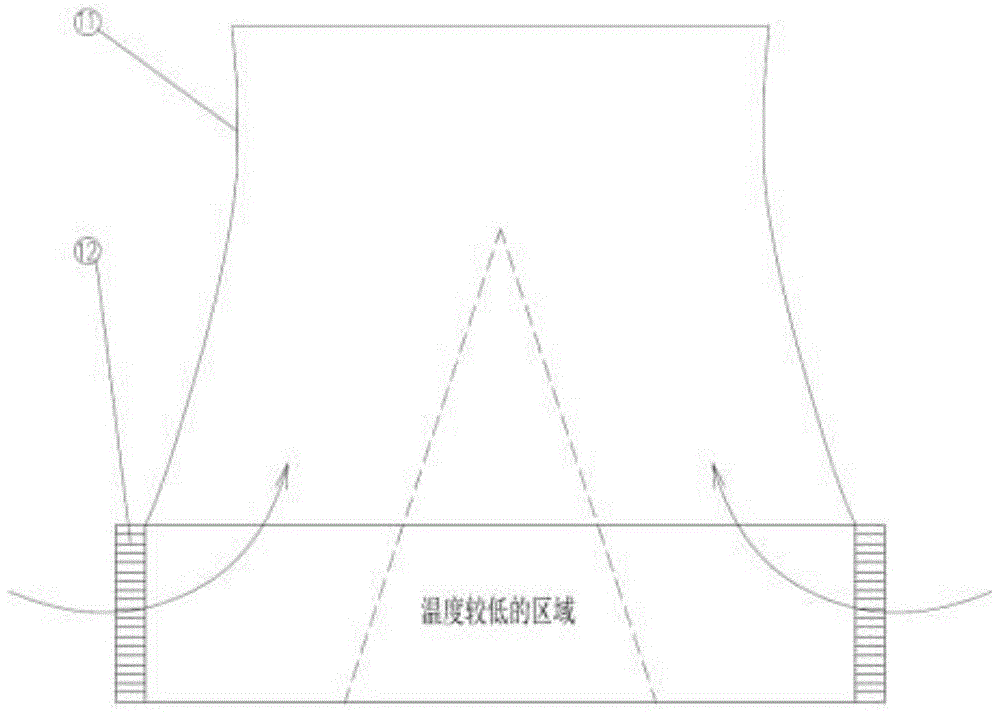

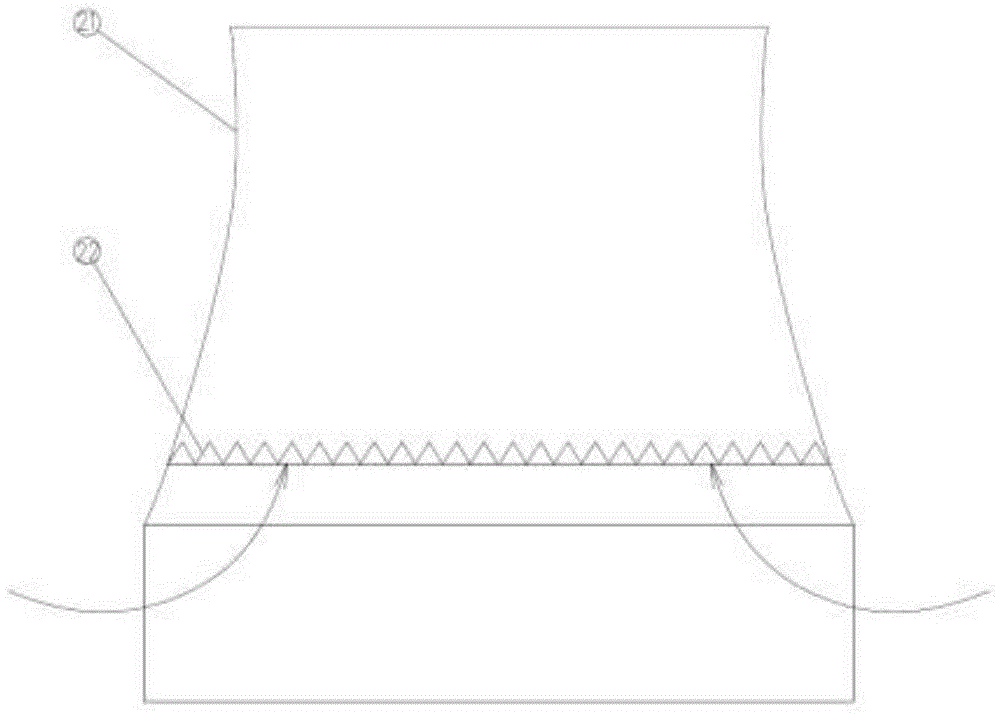

[0043] figure 1 , figure 2 It shows that the prior art intermediate cooling tower is arranged according to the position of the heat exchanger, which can be arranged at the air inlet of the cooling tower ( figure 1 ), can also be arranged inside the tower ( figure 2 ), its existing defects have been pointed out in the background technology. On the basis of the background technology, the present invention proposes a petal-shaped indirect cooling tower. Arrange the cooling triangle to ensure sufficient air natural circulation power, as follows:

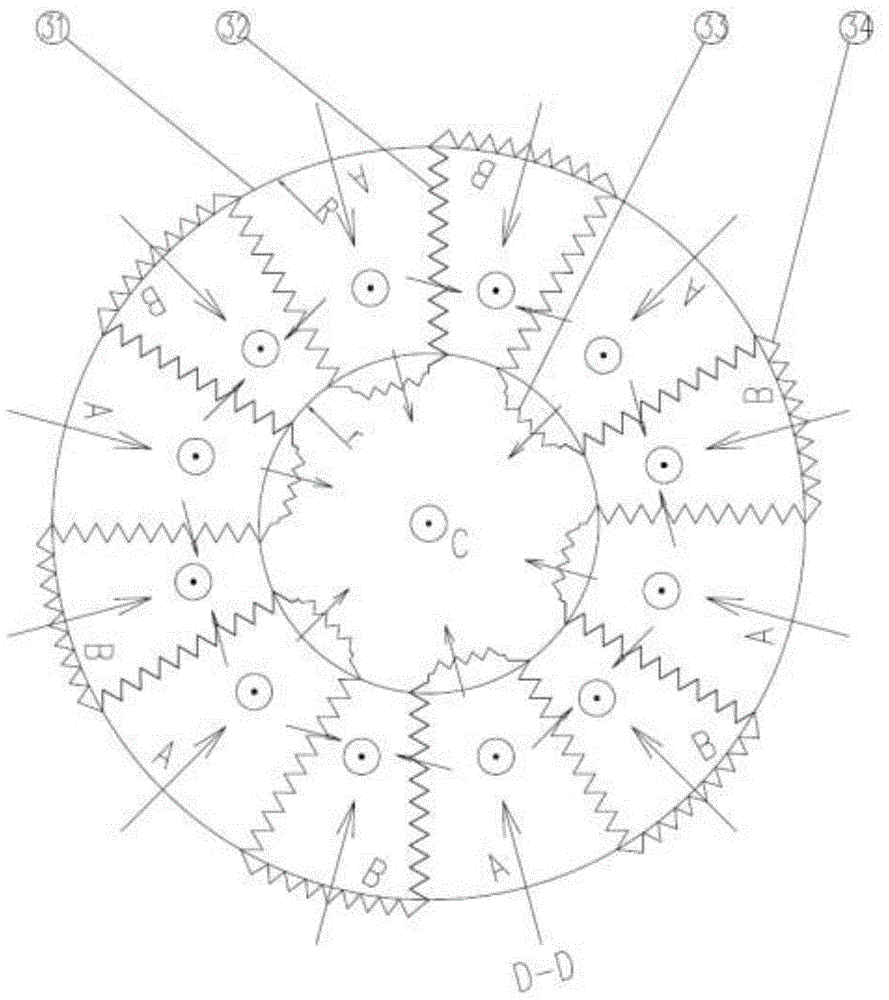

[0044] Such as image 3 (top view), Figure 4 As shown, the indirect cooling tower arranged in a petal shape consists of a tower tube 31, a vertical cooling triangle 34 arranged circumferentially at the outer edge of the diameter of the tower tube bottom, a vertical cooling triangle 32 arranged radially inside the tower tube, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com