Test device for control valve body of speed changer of engineering vehicle

A transmission control and engineering vehicle technology, which is applied in the direction of machine gear/transmission mechanism testing, etc., can solve the problems of low precision, high manual labor intensity, complicated operation, etc., and achieve the effect of high versatility, improved operability and practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

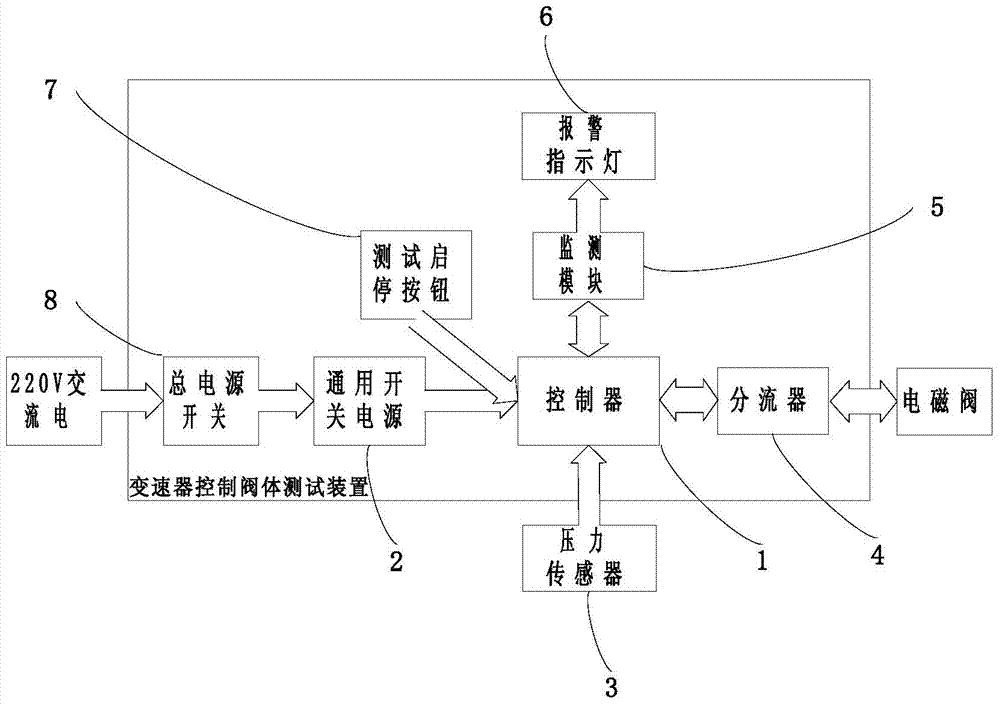

[0025] Embodiment: When in use, 220V AC is connected to the general switching power supply 2 through the main power switch 8 so that the 220V AC is converted into 24V DC to supply power for the entire test device; The upper shunt 4, the specification of the shunt 4 is 2A, 200mV, and the number is ten in total. The controller 1 monitors the current value of the solenoid valve by measuring the voltage value of the shunt 4. Connect the output signal of the pressure sensor 3 to the controller 1. The specification of the pressure sensor 3 is 4Mpa, and the output is a 0-5V signal. There are six pressure sensors 3 in total. The valve body is monitored by measuring the voltage value of the pressure sensor 3 oil pressure value. When carrying out valve body test, press main power switch 2 and test start-stop button 7 successively, then test device just can repeatedly carry out valve body shift cycle test work, if want to stop testing, press test start-stop button 7 again.

[0026] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com