Gasometric porosity measuring method taking temperature effect into consideration

A measurement method and technology of temperature effect, applied in measurement devices, analysis of suspensions and porous materials, instruments, etc., can solve the problems of porosity measurement error, difficult to achieve constant temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1: Take the measurement of sandstone core porosity as an example.

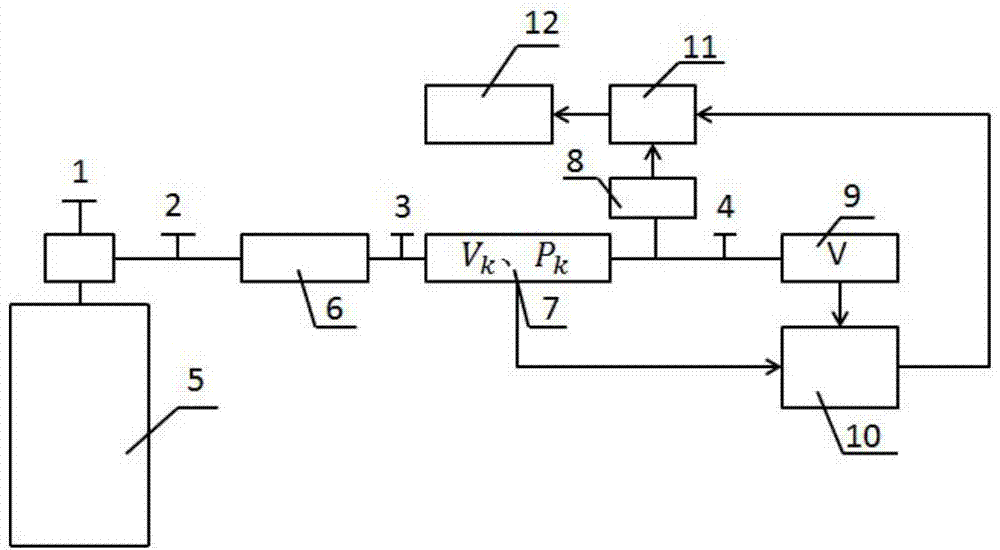

[0050] A gas porosity measurement method considering the temperature effect, using porosity measurement equipment to measure porosity, such as figure 1 As shown, the porosity measurement equipment includes a gas source bottle 5, an air pressure control device 3, an air pressure fine-tuning device 6, a known gas chamber 7 and a rock core chamber 9, and the gas source bottle 5 is connected to a gas source bottle decompression device 1, Control the maximum measured air pressure of the measuring equipment; the gas source bottle decompression device 1 is connected with a gas source communication valve 2 to control the on-off of the gas source; the gas source communication valve 2 is connected with the air pressure fine-tuning device 6 and the air pressure control device 3 in turn , wherein, the air pressure control device 3 controls the general air pressure, and the air pressure fine-tuning device...

Embodiment 2

[0096] Embodiment 2: Taking the measurement of the porosity of carbonate rock as an example, in this implementation, the measurement method and equipment of the porosity are the same as in Embodiment 1.

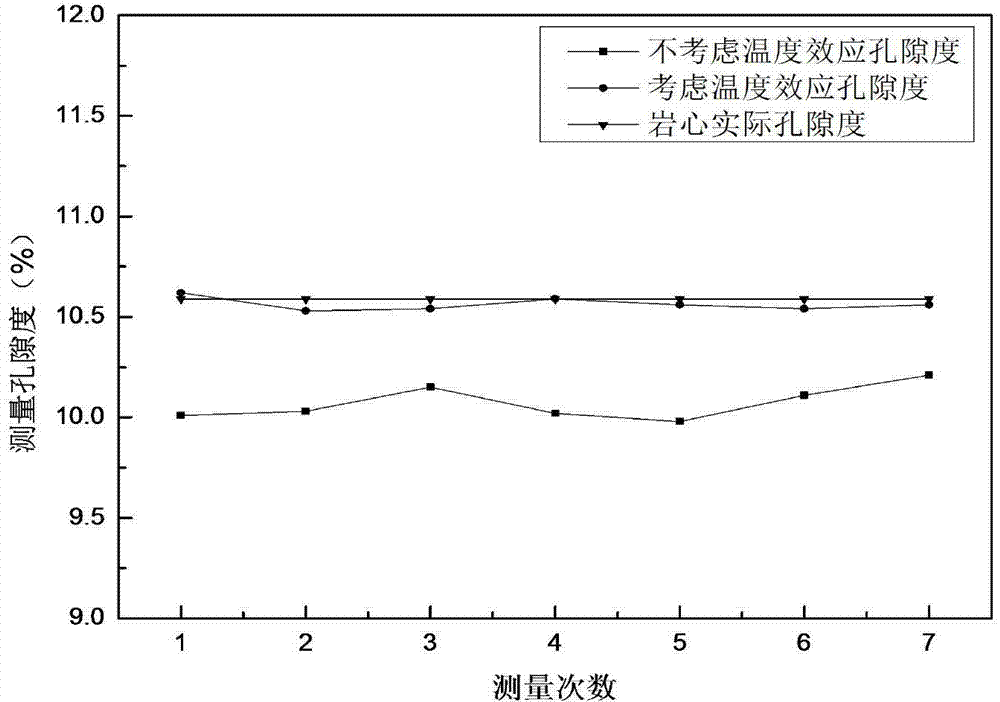

[0097]According to the porosity measurement method in Example 1, the measurement was repeated 7 times, and the porosity obtained by each measurement, the porosity after considering the temperature effect in this embodiment, and the temperature at the beginning and end of the measurement were respectively recorded.

[0098] The experimental data are shown in the table below:

[0099]

[0100] From the above experimental data, it can be seen that in terms of stability, the variance of the 7 measurement results without considering the temperature effect is 0.0178, and the variance of the 7 measurement results after considering the temperature effect is 0.0011; in terms of accuracy, the 7 measurement results without considering the temperature effect The average value of is 14...

Embodiment 3

[0103] Embodiment 3: Taking the porosity measurement of volcanic rock as an example, in this implementation, the porosity measurement method and equipment are the same as in Embodiment 1.

[0104] In order to accurately verify the application effect of the present invention, in this embodiment, when the porosity is measured in the laboratory, the temperature of the air conditioner is adjusted to 30°C on the basis of the room temperature being 18.01°C, and it is considered that the temperature is continuously rising during the measurement process.

[0105] According to the porosity measurement method in Example 1, the measurement was repeated 7 times, and the porosity obtained by each measurement, the porosity after considering the temperature effect in this embodiment, and the temperature at the beginning and end of the measurement were respectively recorded.

[0106] The experimental data are shown in the table below:

[0107]

[0108]

[0109] From the above experiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com