Method of monitoring rusting risk of reinforcement in concrete in situ

A steel corrosion and concrete technology, applied in measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problems of sensor failure, difficulty in providing quantitative analysis, and difficulty in the corresponding relationship between steel corrosion amounts, so as to improve reliability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

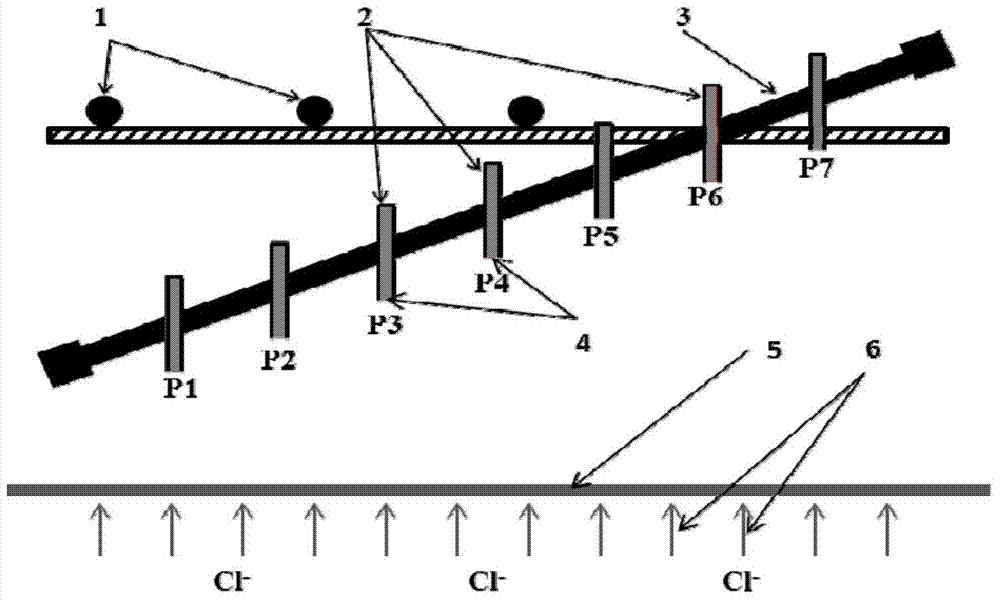

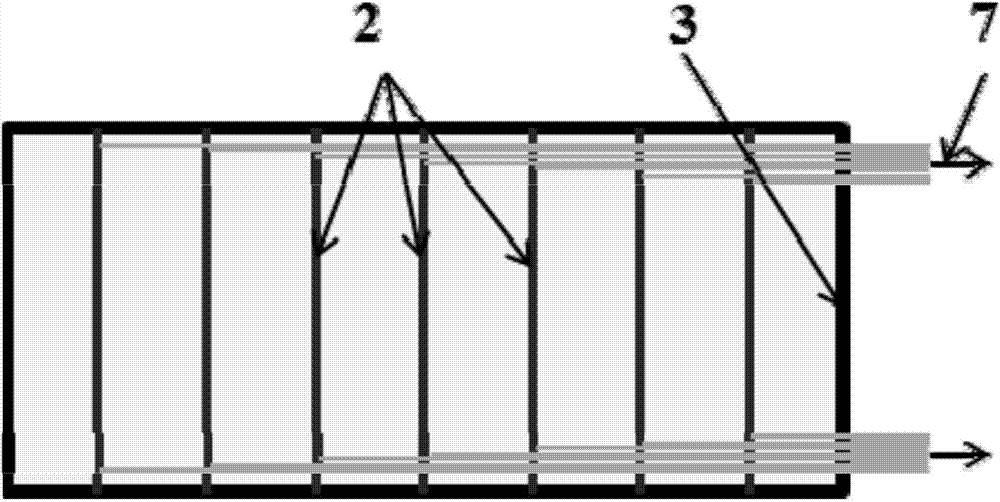

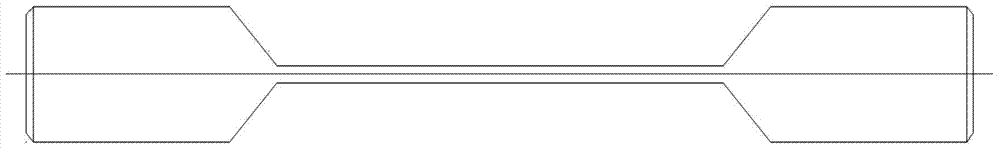

[0025] The schematic layout of the present invention is as figure 1 , 2 As shown, the ladder frame 3 arranges the corrosion monitoring sensing elements 2 at equal intervals, and the depth from the concrete protective layer increases gradually. The structure of steel bar corrosion monitoring components is as follows: Figure 3a , Figure 3b and Figure 4 As shown, the middle steel bar sheet 10 is made of the same material as the longitudinal reinforced steel bar in the concrete structure, and the distributed continuous strain measuring points 11 are arranged at different heights on the cross section of the middle steel bar sheet 10 ( Figure 3a and Figure 3b As shown), the continuous strain measuring point 11 adopts distributed optica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com