Method of automatically detecting joint twitching of steel wire core conveyor belt

An automatic detection and steel rope core technology, applied in the direction of optical testing flaws/defects, image data processing, instruments, etc., can solve problems such as economic losses, affecting production safety, false positives or missing negatives, etc., to improve detection accuracy and ensure safety running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

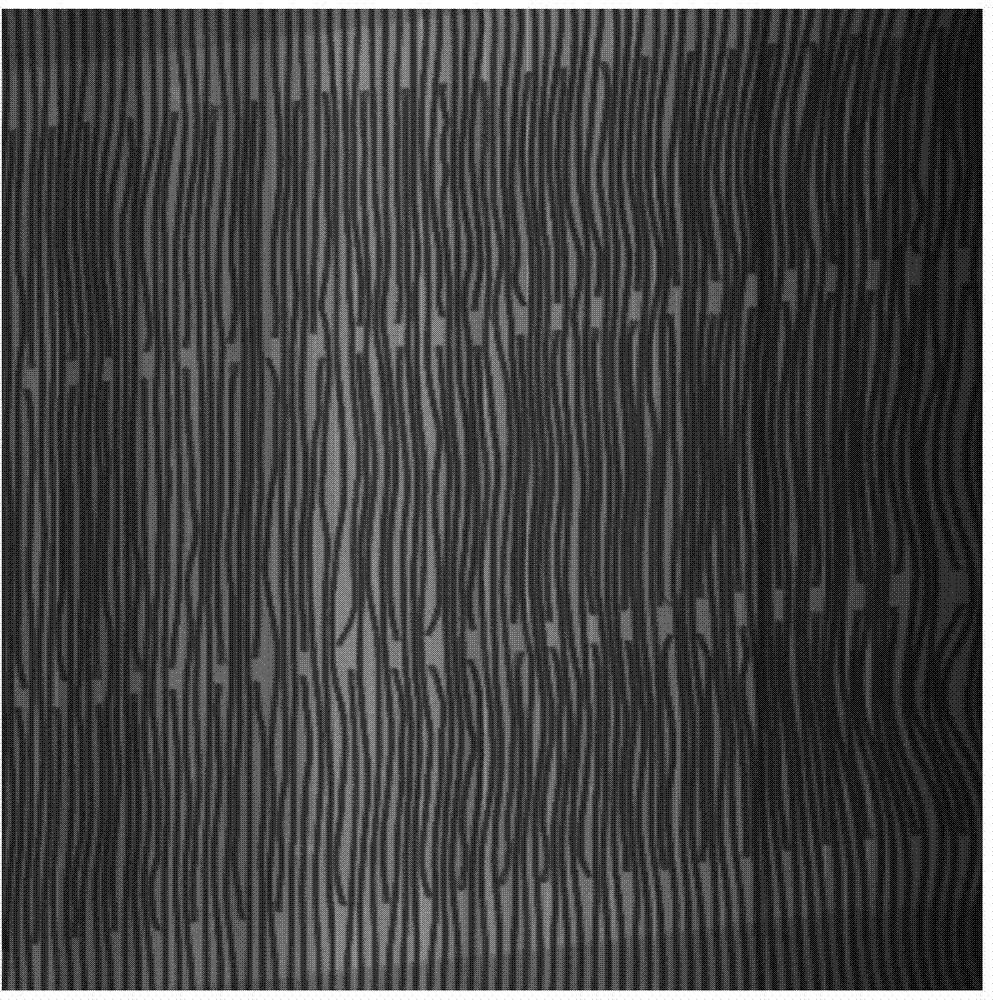

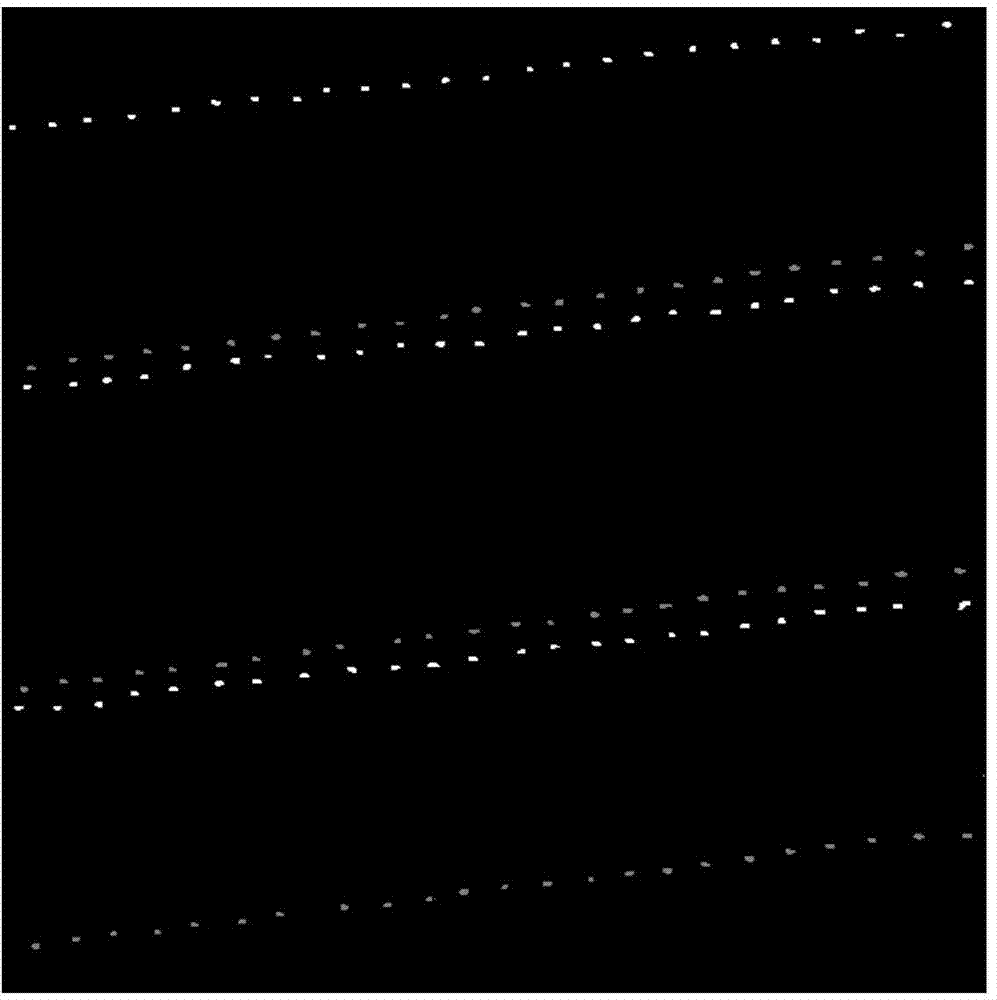

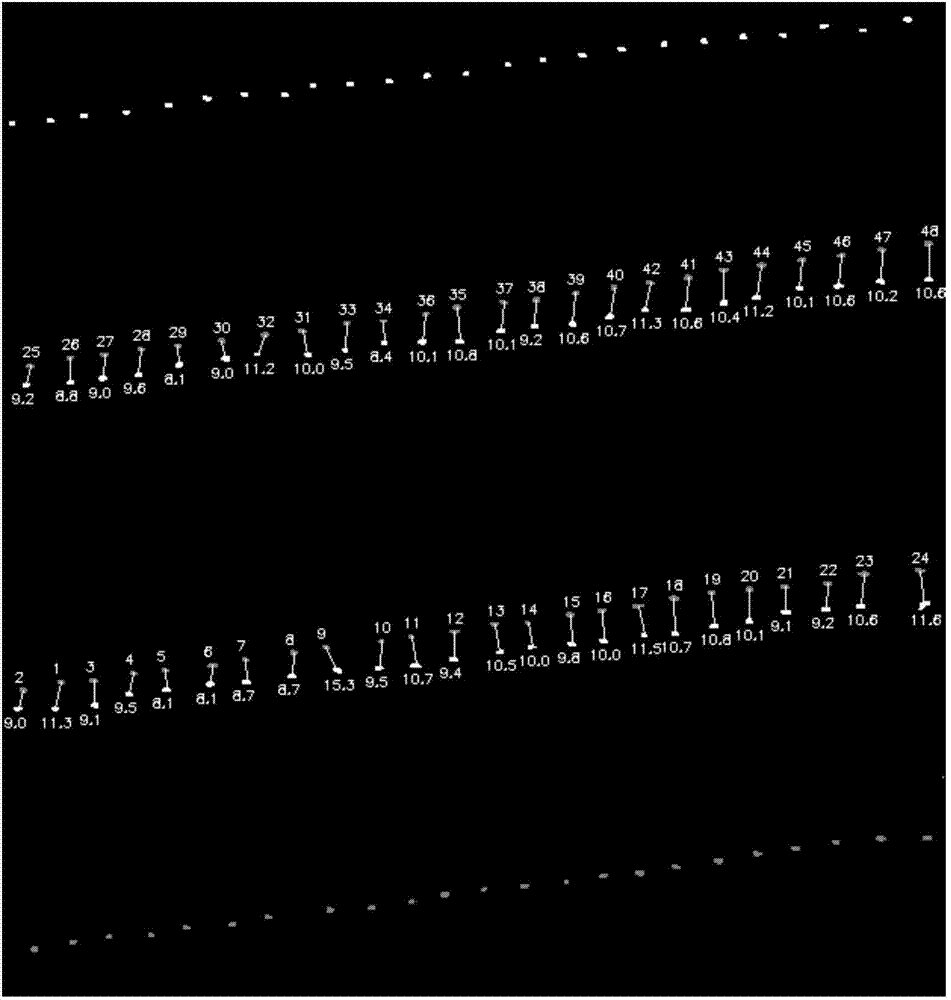

[0012] figure 1 is a schematic diagram of the joint image, figure 2 In order to eliminate the image schematic diagram of isolated points, image 3 It is a schematic diagram of the joint distance; as shown in the figure: the automatic detection method for the joint twitch of the steel cord conveyor belt of the present embodiment includes the following steps: a, performing joint point detection on the joint image to be detected and the reference joint image; b, the joint point image to be inspected Perform surf feature extraction, perform feature matching according to feature values, seek a mapping relationship between the joint image and the reference joint image, and obtain a normalization coefficient; c, perform twitch analysis and calculation according to the normalization coefficient to obtain the twitch distance.

[0013] In this embodiment, the step a specifically includes the following steps: a1, gray level correction; a2, Gaussian filtering; a3, image segmentation; a4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com