Method and device for rapidly judging operation stability of chemical industry production device

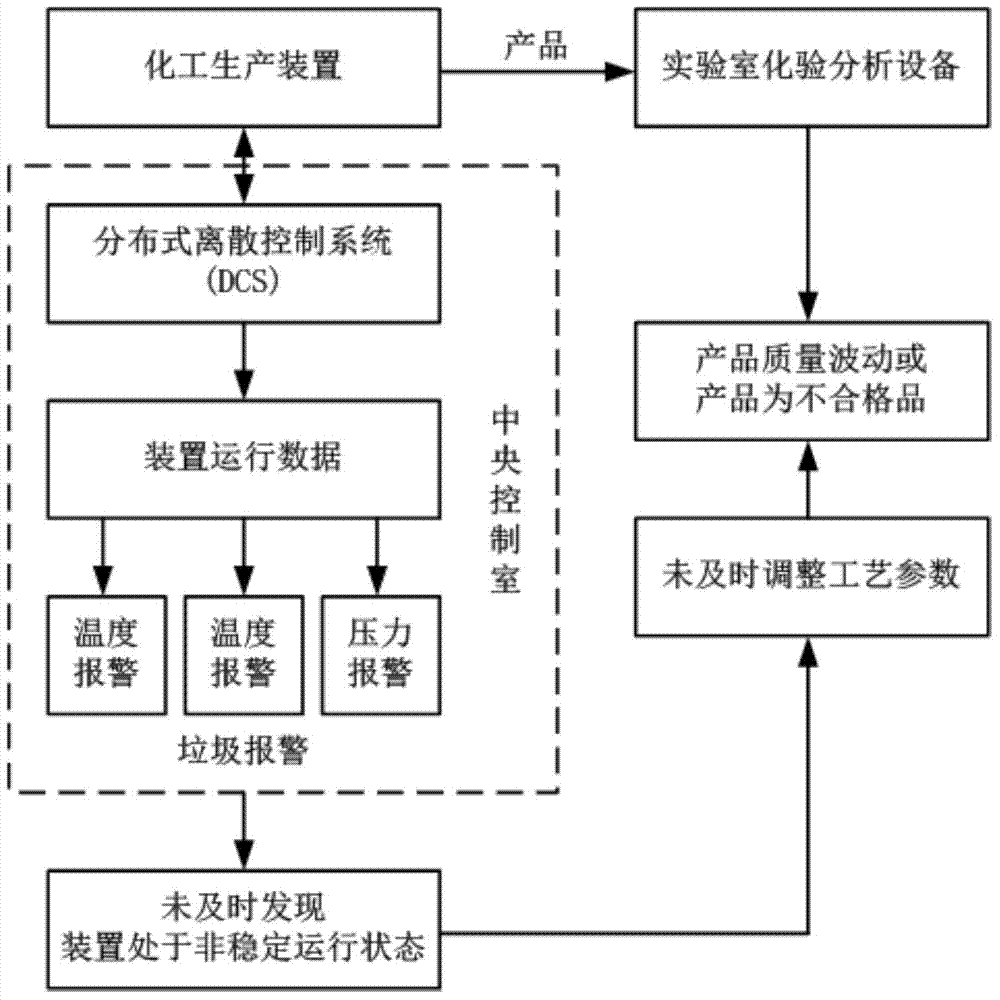

A chemical production and stability technology, which is applied in the fields of manufacturing, chemical industry and metallurgy, can solve the problems that the production process cannot be guaranteed to be stable and full, the failure can not be detected as early as possible, and the failure loss cannot be reduced, so as to improve safety and reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the invention are described in detail below, but the invention can be practiced in many different ways as defined and covered by the claims.

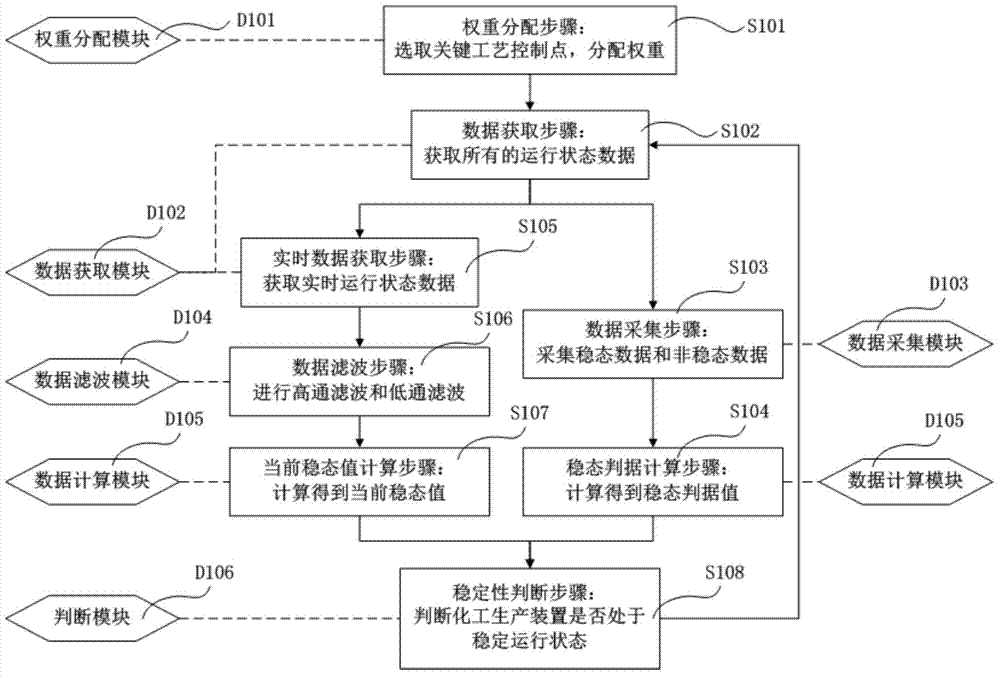

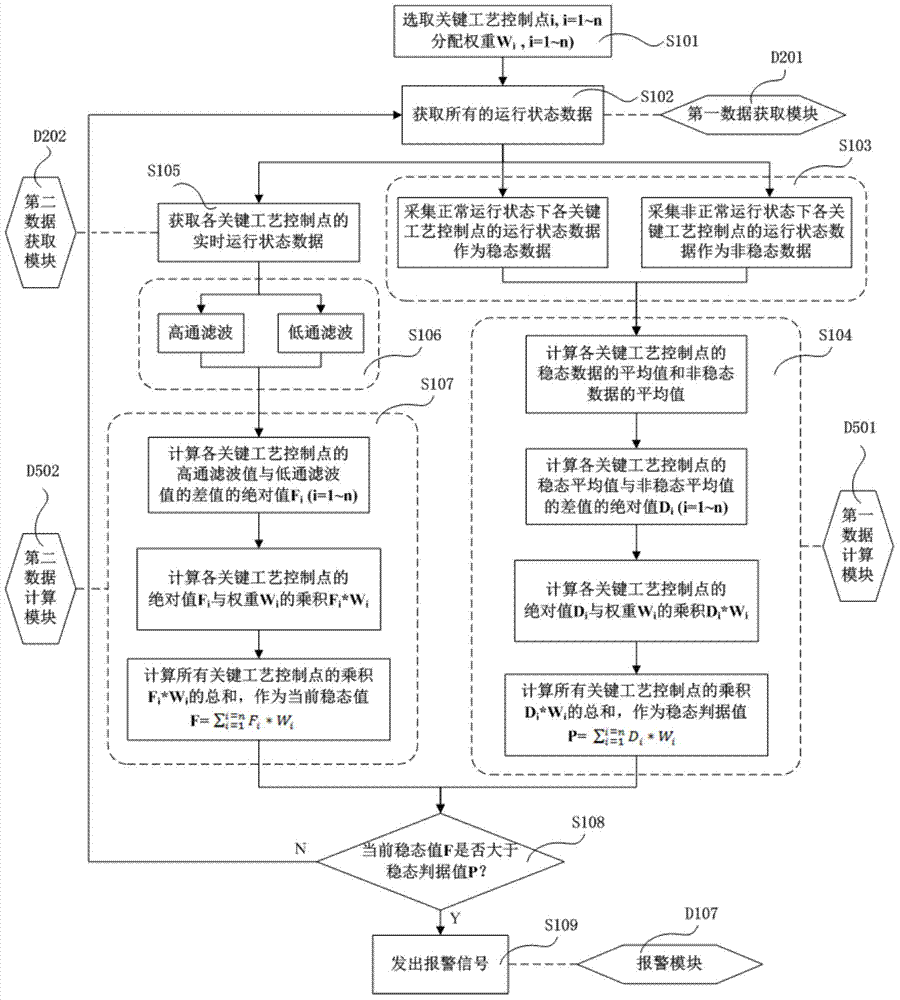

[0029] As a first aspect of the present invention, the present invention provides a method for quickly judging the operational stability of a chemical production plant, see figure 1 shown. The method specifically includes the following steps:

[0030] The data acquisition step S102 and the weight distribution step S101 are respectively: the data acquisition step S102 is to obtain all the operating status data of the chemical production device; the weight distribution step S101 is to select key process control points according to the production requirements of the chemical production device, Process control points are assigned weights respectively;

[0031] Data collection step S103, from all the operating state data, collect the operating state data of each key process control point of the chemical production dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com