A kind of preparation method of high tap density composite cathode material

A composite positive electrode material and tap density technology, applied in battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of difficulty in ensuring the stability and consistency of materials, difficulty in target template manganese carbonate, unfavorable production, etc., to achieve Improved discharge specific capacity and coulombic efficiency, improved rate characteristics, and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

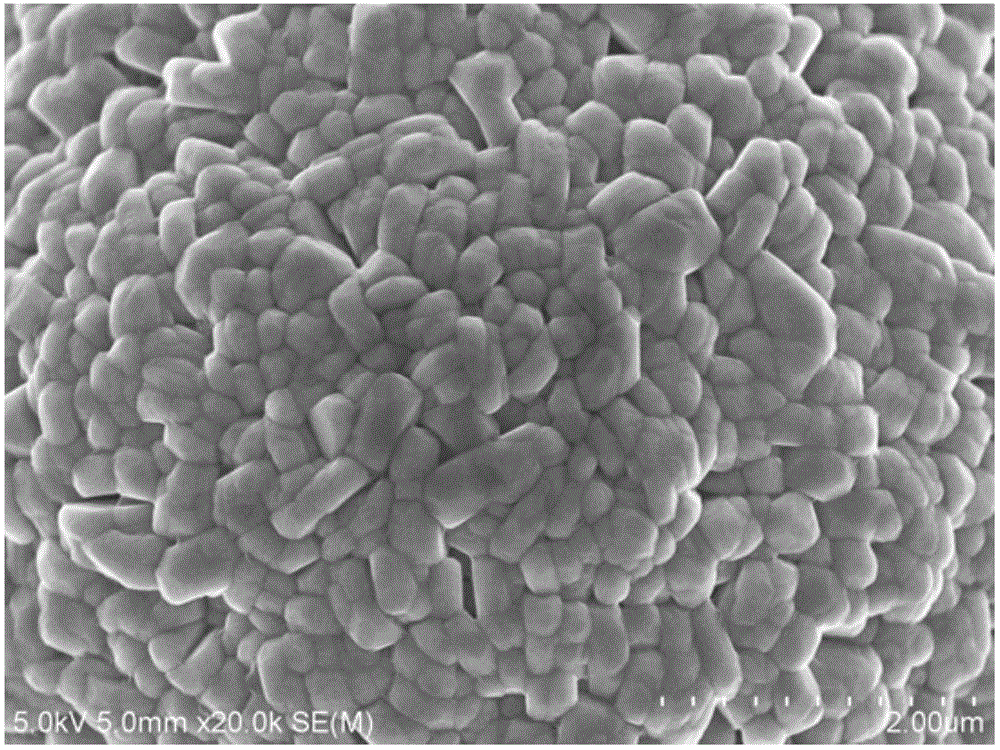

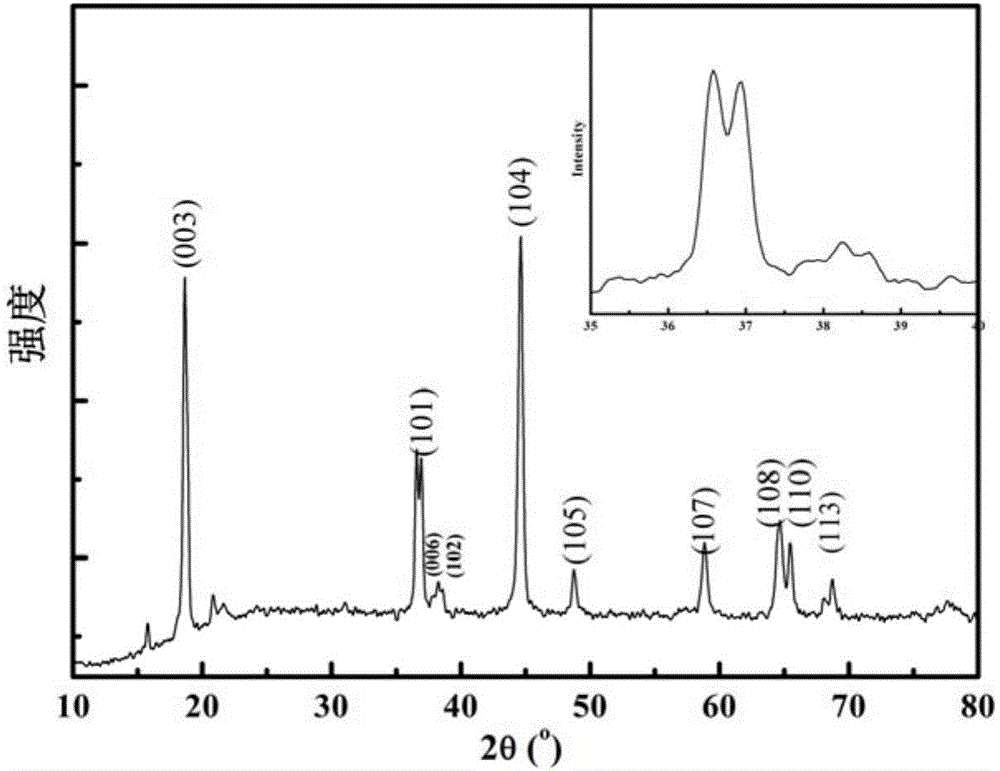

[0035] First press the molecular formula 0.5LiNi 1 / 3 Co 1 / 3 Mn 1 / 3 O 2 -0.5Li 2 MnO 3 The stoichiometric ratio of Mn, Ni, Co to prepare MnSO 4 , NiSO 4 , CoSO 4 The mixed solution, the cation concentration is 2.0mol / L, and then press 0.5LiNi 1 / 3 Co 1 / 3 Mn 1 / 3 O 2 -0.5Li 2 MnO 3 -0.3MnO 2 Medium MnO 2 Add MnO to the stoichiometric ratio 2 Powder, forming a suspension;

[0036] Then prepare Na 2 CO 3 And NH 3 ·H 2 Mixed solution of O, Na 2 CO 3 The concentration is 2.0mol / L, NH 3 ·H 2 The O concentration is 0.24mol / L;

[0037] Use a peristaltic pump to drop the above two solutions into the reaction vessel, and control the pH value to be around 7.5. The water bath is heated at 50°C and contains MnO. 2 The volume ratio of the suspension to the lye is 1:1.1, and the reaction is 24h. After the reaction is completed, suction filtration, washing, and drying in a vacuum oven at 120°C for 12 hours to obtain MCO 3 -MnO 2 Compound (M=Mn, Ni, Co);

[0038] MCO 3 -MnO 2 The compound and 0.38LiCl-0...

Embodiment 2

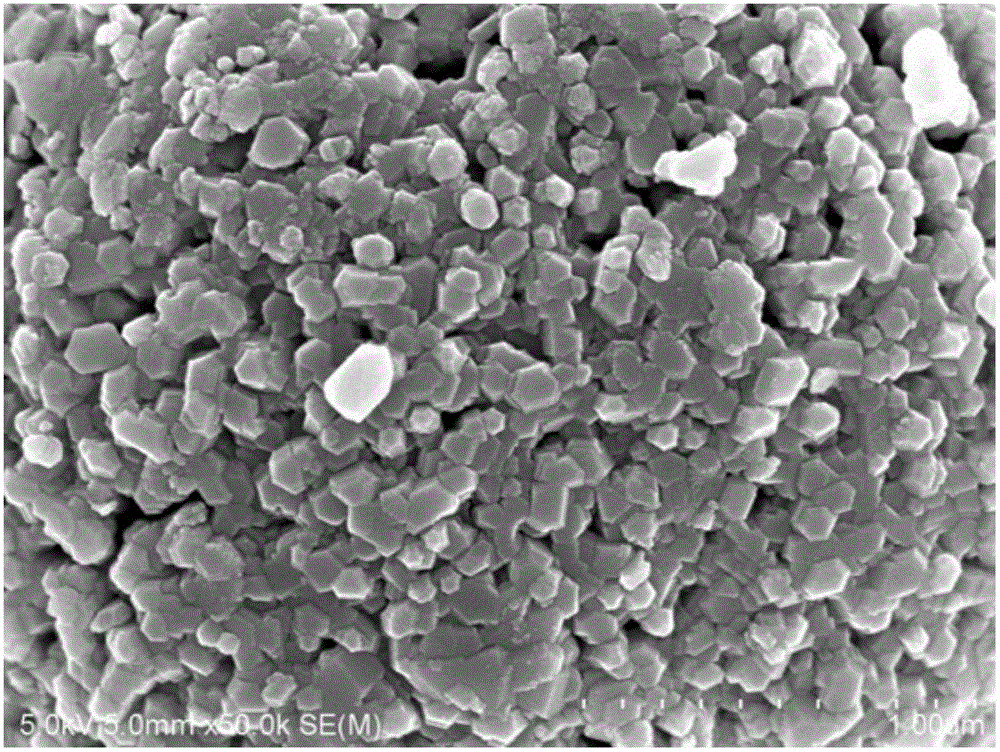

[0042] First press the molecular formula 0.5LiNi 1 / 3 Co 1 / 3 Mn 1 / 3 O 2 -0.5Li 2 MnO 3 The stoichiometric ratio of Mn, Ni, Co to prepare MnSO 4 , NiSO 4 , CoSO 4 The mixed solution, the cation concentration is 2.0mol / L, and then press 0.5LiNi 1 / 3 Co 1 / 3 Mn 1 / 3 O 2 -0.5Li 2 MnO 3 -0.3MnO 2 Medium MnO 2 Add MnO to the stoichiometric ratio 2 Powder, forming a suspension;

[0043] Prepare Na 2 CO 3 And NH 3 ·H 2 Mixed solution of O, Na 2 CO 3 The concentration is 2.0mol / L, NH 3 ·H 2 The O concentration is 0.24mol / L;

[0044] Use a peristaltic pump to drop the above two solutions into the reaction vessel, and control the pH value to be around 7.5. The water bath is heated at 50°C and contains MnO. 2 The volume ratio of the suspension to the lye is 1:1.1, and the reaction is 24h. After the reaction is completed, suction filtration, washing, and drying in a vacuum oven at 120°C for 12 hours to obtain MCO 3 -MnO 2 Compound (M=Mn, Ni, Co);

[0045] MCO 3 -MnO 2 Complex with 0.6LiNO 3 -0.4LiOH ...

Embodiment 3

[0047] First press the molecular formula 0.5LiNi 1 / 3 Co 1 / 3 Mn 1 / 3 O 2 -0.5Li 2 MnO 3 The stoichiometric ratio of Mn, Ni, Co to prepare MnSO 4 , NiSO 4 , CoSO 4 The mixed solution, the cation concentration is 2.0mol / L, and then press 0.5LiNi 1 / 3 Co 1 / 3 Mn 1 / 3 O 2 -0.5Li 2 MnO 3 -0.3MnO 2 Medium MnO 2 Add MnO to the stoichiometric ratio 2 Powder, forming a suspension;

[0048] Prepare Na 2 CO 3 And NH 3 ·H 2 Mixed solution of O, Na 2 CO 3 The concentration is 2.0mol / L, NH 3 ·H 2 The O concentration is 0.24mol / L;

[0049] Use a peristaltic pump to drop the above two solutions into the reaction vessel, and control the pH value to be around 7.5. The water bath is heated at 50°C and contains MnO. 2 The volume ratio of the suspension to the lye is 1:1.1, and the reaction is 24h. After the reaction is completed, suction filtration, washing, and drying in a vacuum oven at 120°C for 12 hours to obtain MCO 3 -MnO 2 Compound (M=Mn, Ni, Co);

[0050] MCO 3 -MnO 2 Complex with 0.3LiCl-0.7LiNO 3 A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com