Structure for a dish-type point-based solar concentration system, and concentration system including said structure

A solar concentrating, dish-shaped technology, applied in the field of solar concentrating systems, can solve the problems of expensive, heavy, and complicated manufacturing, and achieve the effects of avoiding stress, ensuring quality, and compact transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

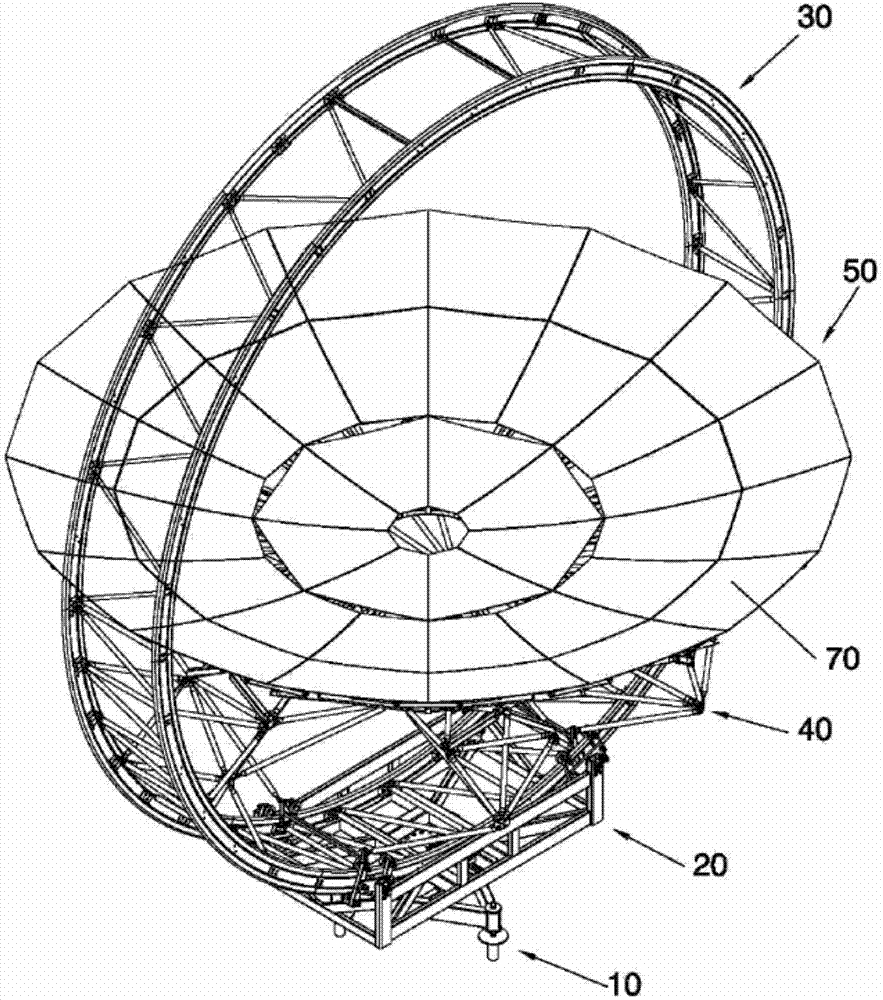

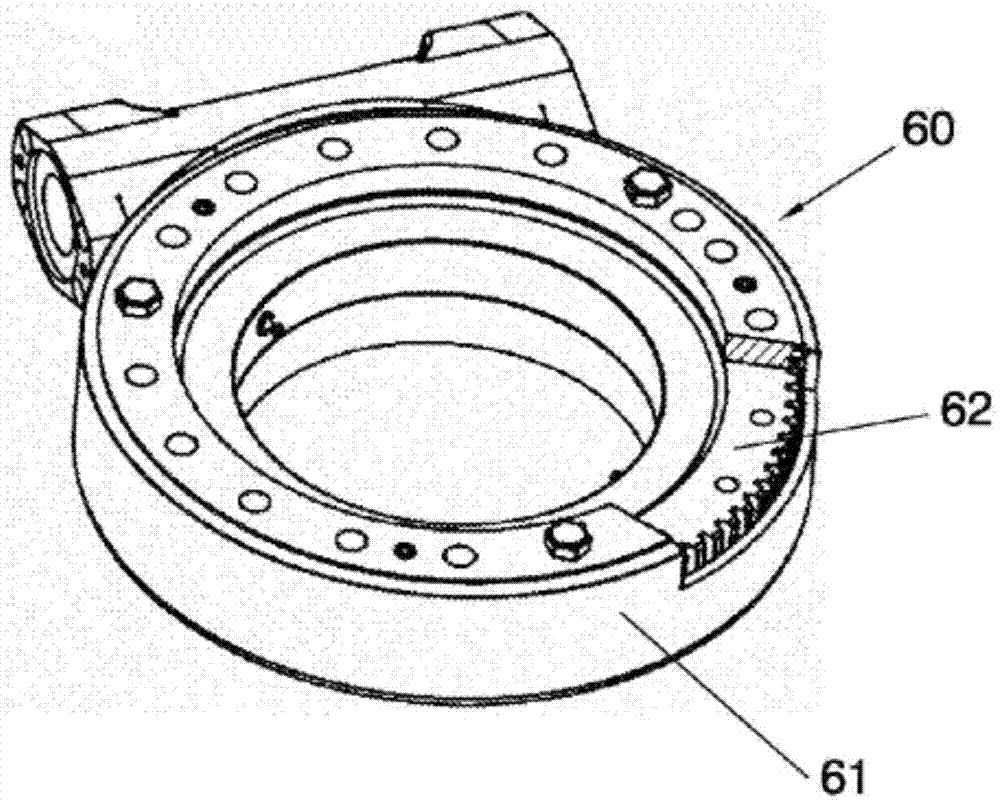

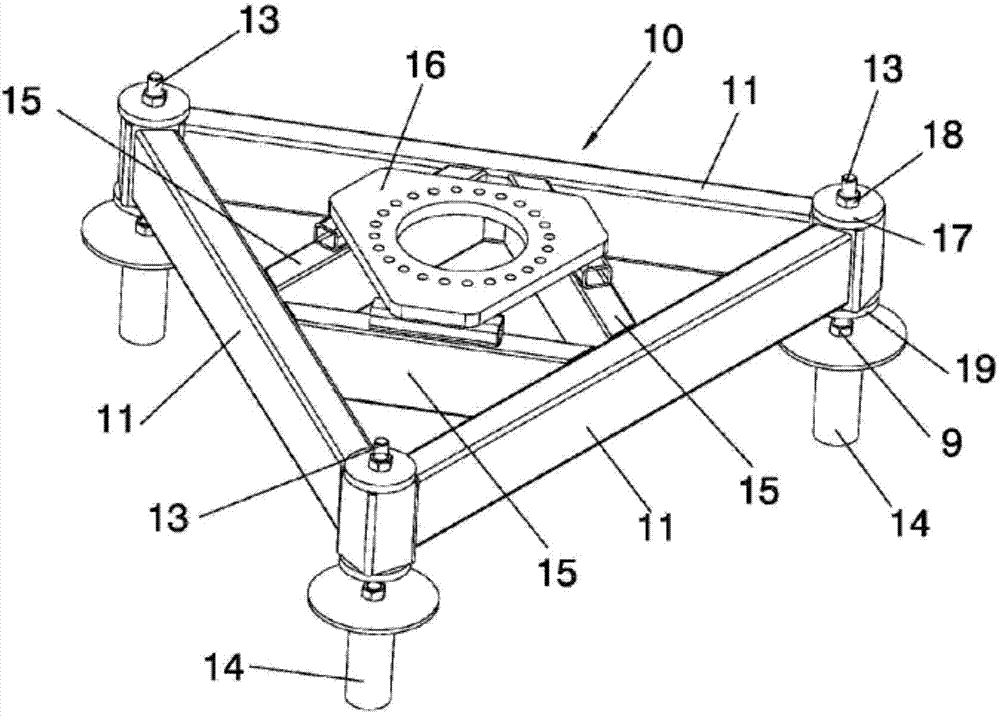

[0056] Below, with the help of the Figures 1 to 15 To illustrate the detailed description of the present invention.

[0057] In the following, the reference numerals corresponding to the figures used in the description of the preferred embodiment are given in the list.

[0058] 10 anchor substructure

[0059] 11 First profile

[0060] 13 bolts

[0061] 14 pile foundation

[0062] 15 Second profile

[0063] 16 first plate

[0064] 17 upper base

[0065] 18 upper nut

[0066] 19 lower base

[0067] 9 lower nut

[0068] 20 Trace Substructure

[0069] 21 pillars

[0070] 22 second plate

[0071] 23 sliders

[0072] 24 rolling elements

[0073] 25 chain

[0074] 30 driver substructure

[0075] 31 ring frame

[0076] 32 connecting rod

[0077] 33 segments

[0078] 34 bend rod

[0079] 35 containers

[0080] 40 link substructure

[0081] 41 central core

[0082] 42 modules

[0083] 43 first triangle

[0084] 44 First Pedestal

[0085] 45 First base apex

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com