Treatment device and method for coating waste gas

A waste gas and coating technology, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, can solve the problems of low purification rate and low recovery rate, improve the recovery rate of absorbents, reduce operating costs, and equipment investment low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

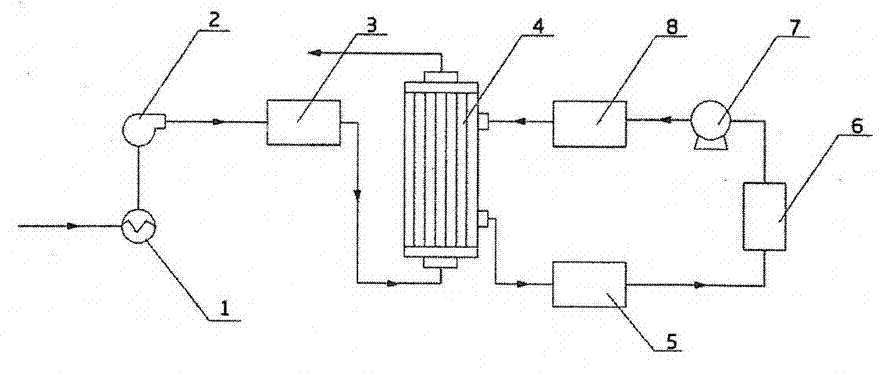

[0028] A coating exhaust gas treatment method, comprising the following steps:

[0029] (1) Add absorbent silicone oil at a temperature of 20°C to the liquid storage tank 6;

[0030] (2) The absorbent silicone oil in the liquid storage tank 6 enters the membrane absorber 4 from the shell side inlet of the membrane absorber 4 through the constant flow pump 7 through the liquid flow controller 8; the membrane module in the membrane absorber 4 adopts Hydrophobic polypropylene hollow fiber membrane, the filling factor is 0.4, the porosity is 0.5, and the pressure difference between the gas-liquid two-phase on both sides of the membrane is 0.03Mpa;

[0031] (3) Set the concentration to 300mg / m 3 , the flow rate is 10m 3 / h, the coating exhaust gas at a temperature of 40°C is cooled by the filter 1, and then enters the tube of the membrane absorber 4 by the fan 2 through the gas flow controller 3, and the exhaust gas passes through the fiber membrane and is absorbed by th...

Embodiment 2

[0035] A coating exhaust gas treatment method, comprising the following steps:

[0036] (1) Add absorbent diesel-water at a temperature of 25°C into the liquid storage tank 6;

[0037] (2) The absorbent diesel-water in the liquid storage tank 6 enters the membrane absorber 4 from the shell side inlet of the membrane absorber 4 through the constant flow pump 7 through the liquid flow controller 8; the membrane module in the membrane absorber 4 adopts Hydrophobic polypropylene hollow fiber membrane, the filling factor is 0.4, the porosity is 0.5, and the pressure difference of gas-liquid two-phase on both sides of the membrane is 0.005Mpa;

[0038] (3) Set the concentration to 100mg / m 3 , the flow rate is 8m 3 / h, the coating exhaust gas at a temperature of 20°C is cooled by the filter 1, and then enters the tube of the membrane absorber 4 by the fan 2 through the gas flow controller 3, and the exhaust gas passes through the fiber membrane and is absorbed by the absorbent ...

Embodiment 3

[0042] A coating exhaust gas treatment method, comprising the following steps:

[0043] (1) Add F-BDO absorbent and SD-VOC at a temperature of 10°C to the liquid storage tank 6 polymer absorbent;

[0044] (2) The F-BDO absorbent and SD-VOC in the storage tank 6 The polymer absorbent enters the membrane absorber 4 from the shell side inlet of the membrane absorber 4 through the constant flow pump 7 through the liquid flow controller 8; the membrane module in the membrane absorber 4 adopts a hydrophobic polypropylene hollow fiber membrane, and the filling factor is 0.4, the porosity is 0.5, and the pressure difference between the gas-liquid two-phase on both sides of the membrane is 0.01Mpa; the membrane absorber 4 adopts two stages in series;

[0045] (3) Set the concentration to 50mg / m 3 , the flow rate is 6m 3 / h, the coating exhaust gas at a temperature of 30°C is cooled by the filter 1, and then enters the tube of the membrane absorber 4 by the fan 2 through the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com