A powder classification device and method

A grading device and a grading method technology, applied in chemical instruments and methods, solid separation, separating solids from solids with airflow, etc., can solve the problem that powder properties cannot meet the requirements, fast loss of screen mesh, unstable powder particle size, etc. problems, to achieve the effect of prolonging the continuous grading time, improving the grading accuracy and preventing the powder from escaping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

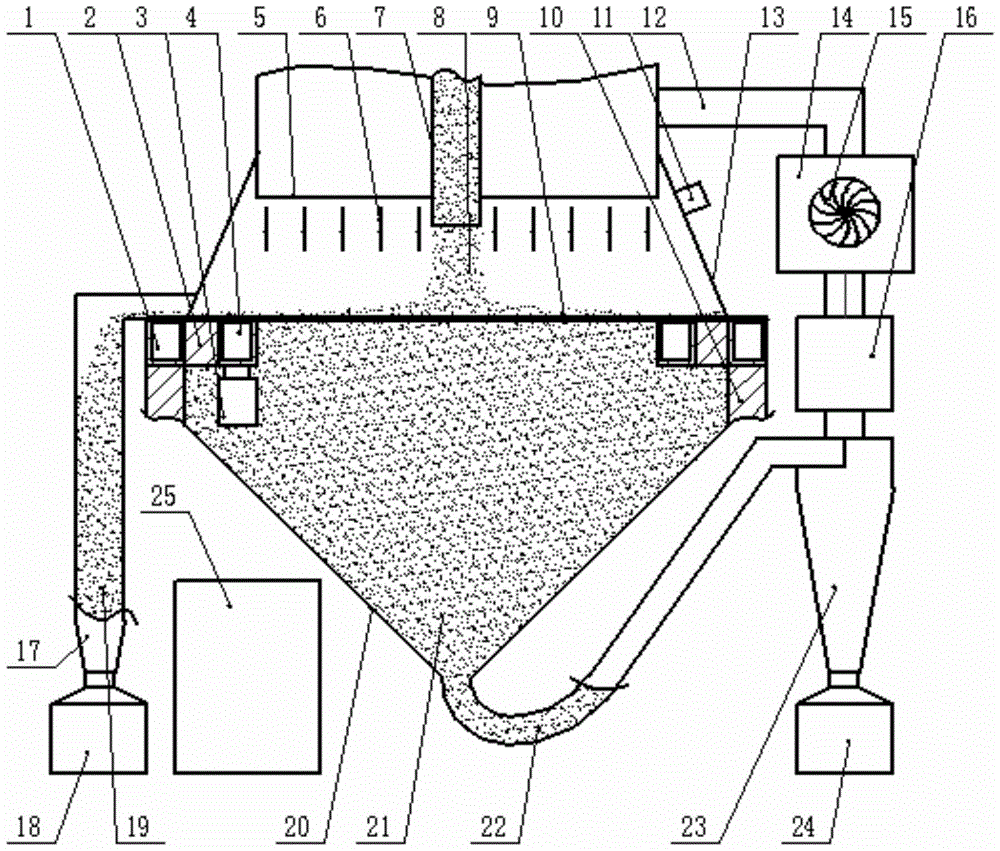

[0080] Hierarchical SnAg 3 Cu 0.5 powder. Such as figure 1 As shown, the device includes a powder supply part, a gas supply part, a classification part, a collection part, a purification part, a control part, an auxiliary part and other parts. The powder supply part includes the powder supply pipe 7 and other parts, the gas supply part includes the fan 15, the fan chamber 14, the air inlet pipe 12 and the air distributor 5, and the classification part includes the support ring 1, the connecting rib 2, the vibration ring 4, and the vibration source 3 , screen 9, base 10 and other parts, the collection part includes powder outlet pipe 17, first powder collection tank 18, powder collection cone 20 and other parts, and the purification part includes cyclone dust collector 23, filter 16, fan chamber 14 and other parts , the control part includes the control cabinet (PLC) 25, the pressure sensor 11 and other parts, and the auxiliary part includes the enclosure 13, pipelines and o...

Embodiment 2

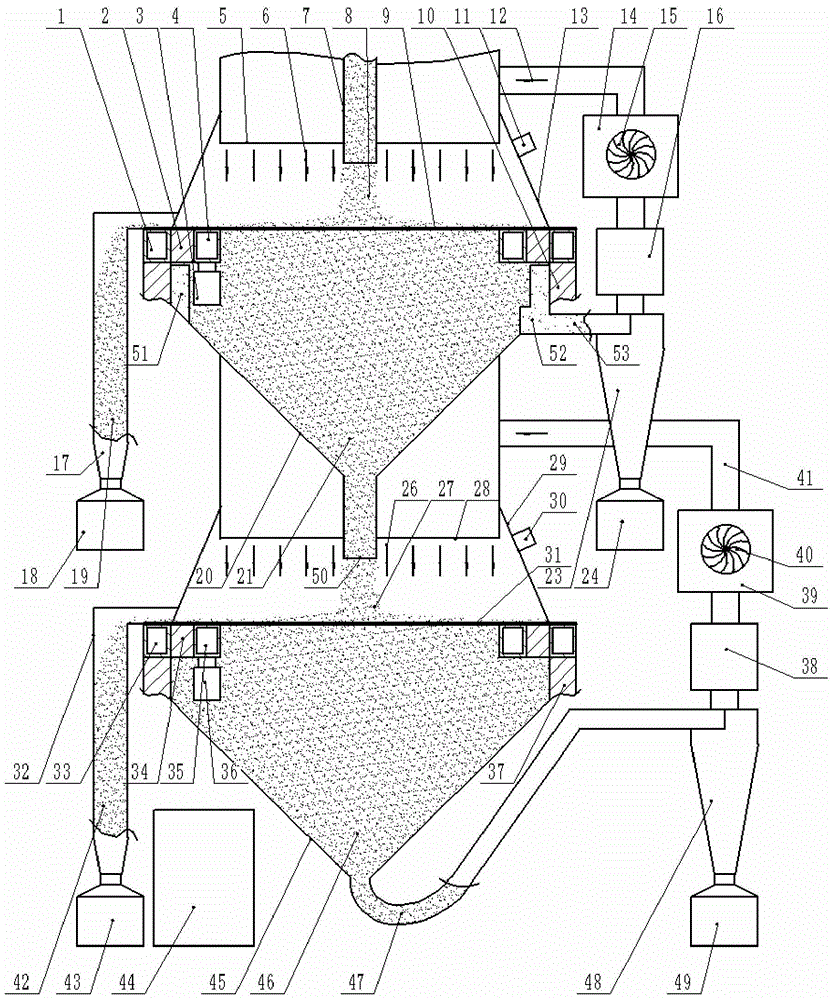

[0085] Classified SnBi58 powder. The use of secondary classification devices, such as figure 2 As shown, it is composed of two-stage grading units connected in series. The difference is that in the first grading device, the powder collecting cone 20 is not connected with the conveying pipe 22, but connected with the secondary powder feeding pipe 50, directly passing through the The powder after the first stage classification is injected into the secondary screen 31, and the wind collecting ring 51 is added at the same time. The wind collecting ring 51 is connected to the cyclone dust collector 23 through the adapter 52 and the connecting pipe 53, and the other parts are connected to the primary classifying device. basically the same.

[0086]The classification atmosphere is nitrogen. The powder 8 is transported from the airtight container to the powder feeding pipe 7 through the electromagnetic vibrating powder feeder, and then falls onto the screen 9 (230 mesh) through the...

Embodiment 3

[0091] Classified SnAg0.3Cu0.7 powder. The use of secondary classification devices, such as figure 2 shown. The staging atmosphere is argon. The powder 8 is conveyed from the airtight container to the powder feeding pipe 7 through the electromagnetic vibrating powder feeder, and then falls onto the screen 9 (400 mesh) through the powder feeding pipe 7. The base 10 is driven by a known rotary vibration machine to generate three-dimensional vibrations, which are transmitted to the support ring 1, and then transmitted to the screen 9 by the support ring 1, so as to realize the primary classification of the powder. The frequency of the high-frequency vibration used to clean the screen cloth 9 is 47KHz, and its vibration mode is a pulse mode. The powder 8 passing through the primary screen 9, except that a small amount of ultrafine powder enters the wind collection ring 51, then settles to the second powder collection tank 24 through the cyclone dust collector 23 and enters the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com